Introduction

We have just taken on the ownership of this camper from Kelly and Karl and hope to have it on the road within the next six months.

DSC_6177 by Peter Thompson, on Flickr

DSC_6177 by Peter Thompson, on Flickr

Not only is it a really lovely vehicle, it was also a pleasure to buy it from such a genuine and really nice couple. There was a huge amount of interest in the sale and I am really appreciative that I was favoured to be the buyer ; so many thanks Karl.

DSC_6176 by Peter Thompson, on Flickr

DSC_6176 by Peter Thompson, on Flickr

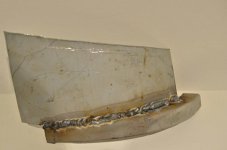

There is a certain amount of essential welding to do underneath, which will add to the welding that has been done in the past. It is currently pretty solid underneath but not as pretty as it could be. I hope to tidy as I go and then work around the bodywork. This has signs of a lot of filler and there is rust poking through in places, but it looks like we will be able to get using it soon.

There are a number of mechanical issue but nothing too onerous and it starts and runs really well.

So a rolling restoration to usable standards.

I just need to get the roof open now!

Watch this space as I document my progress.

Not only is it a really lovely vehicle, it was also a pleasure to buy it from such a genuine and really nice couple. There was a huge amount of interest in the sale and I am really appreciative that I was favoured to be the buyer ; so many thanks Karl.

There is a certain amount of essential welding to do underneath, which will add to the welding that has been done in the past. It is currently pretty solid underneath but not as pretty as it could be. I hope to tidy as I go and then work around the bodywork. This has signs of a lot of filler and there is rust poking through in places, but it looks like we will be able to get using it soon.

There are a number of mechanical issue but nothing too onerous and it starts and runs really well.

So a rolling restoration to usable standards.

I just need to get the roof open now!

Watch this space as I document my progress.