theoneandonly

Prominent member

For those that wanted to see the full version of Alfaobd log. New battery fitted and no airbag issues

full licienced version android

___________________________

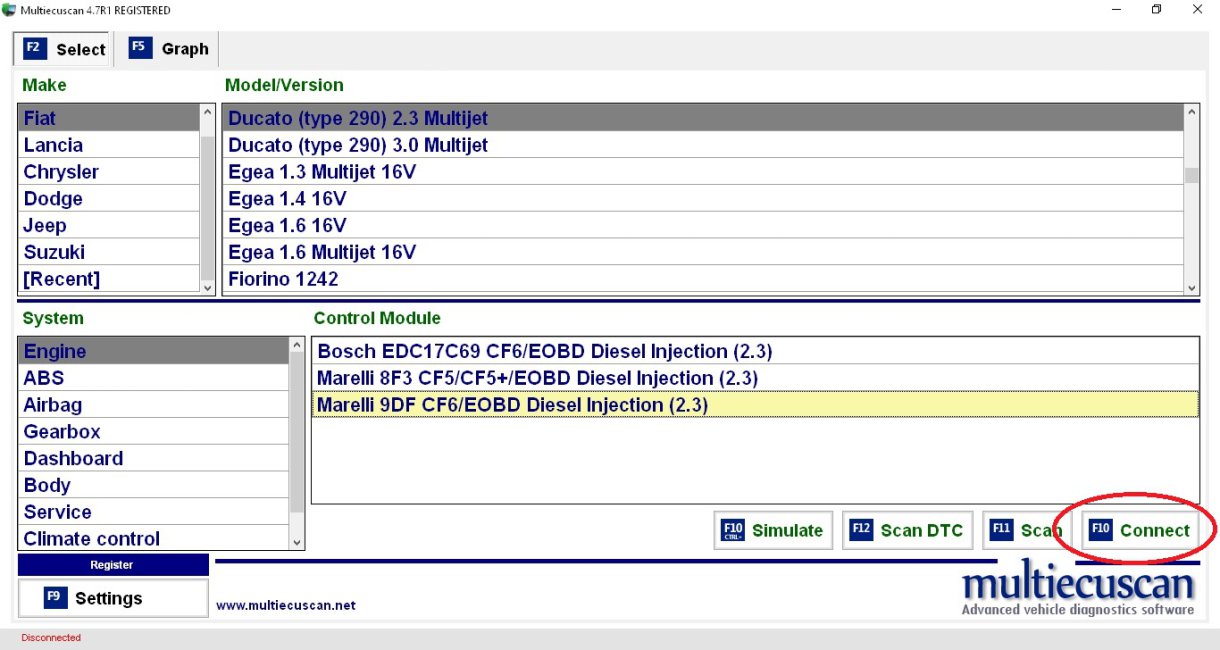

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:00:07.428

EGR high pressure valve duty cycle command:

EGR high pressure valve opening/closing sense: Opening

DEVICE INFO:

Fiat drawing number: 55271527

VMI:

VDS:

VIS:

Hardware number: MJ9DFHW000

Hardware version: 00

Software number: 4L43A128

Software version: 0028

Homologation number: 9DF.A1

ISO code: 0001500814

SINCOM:

Factory:

Serial No:

VIN - Original:

ECU Time Stamps (RAM): 23683.00 min

ECU Time Stamps From Key On (RAM): 45.00 sec

Speed limiter omologation: 255.00 km/h

Driven distance too low viscosity recognition: 0.00 km

EGR high pressure valve duty cycle command:

EGR high pressure valve opening/closing sense: Opening

EGR high pressure valve control status:

EGR high pressure valve offset learning: Disabled

EGR high pressure valve position control: Disabled

EGR high pressure valve air quantity control: Enabled

EGR high pressure valve last offset learnt: 0.00 mm

Number of consecutive interrupted regenerations by key off: 0.00

Driven distance since Diesel Particulate Filter lamp ON: 0.00 km

Mission profile in the engine life:

Engine life time: 342.00 H

A1 Hill: 0.00 %

B1 Fast Highway: 1.00 %

C1 Extra Urban: 50.00 %

D1 City: 13.00 %

E1 Heavy Urban: 17.00 %

F1 Highway WarmUp: 0.00 %

G1 Extra Urban Engine Cold: 6.00 %

H1 Extreme Cold Engine: 0.00 %

I1 Cut-off: 0.00 %

L1 DTD - Hot: 6.00 %

Percentage of the mission profile M1: 2.00 %

Mission profile during Diesel Particulate Filter regeneration:

Engine life time: 224.00 min

A2 Hill: 0.00 %

B2 Fast Highway: 6.00 %

C2 Extra Urban: 59.00 %

D2 City: 17.00 %

E2 Heavy Urban: 4.00 %

F2 Highway WarmUp: 0.00 %

G2 Extra Urban Engine Cold: 1.00 %

H1 Extreme Cold Engine: 0.00 %

I2 Cut-off: 0.00 %

L2 DTD - Hot: 10.00 %

M2: 0.00 %

Mission profile since last Diesel Particulate Filter regeneration:

Engine life time: 132.00 min

A3 Hill: 0.00 %

B3 Fast Highway: 0.00 %

C3 Extra Urban: 23.00 %

D3 City: 8.00 %

E3 Heavy Urban: 50.00 %

F3 Highway WarmUp: 0.00 %

G3 Extra Urban Engine Cold: 11.00 %

H2 Extreme Cold Engine: 0.00 %

I3 Cut-off: 0.00 %

L3 DTD - Hot: 3.00 %

M3: 1.00 %

Engine condition status 1:

Water In Fuel: Not present

Glow plugs activated: Yes

DPF Regeneration mode: High oxygen concentration

Lambda upstream probe status: Not active,

EGR high pressure cooler bypass (exhaust gas cooled): Off

EGR high pressure valve control closed loop: Disabled

Boost control closed loop: Not active,

Particulate filter regeneration: Off

Key On Counter (EEPROM): 23683.00 min

CAN Communication Status:

Manual Trasmission Automated or Robotic Gear status: NO FAULTS

Braking System Module status: NO FAULTS

Body Control Module status: NO FAULTS

Engine Control Module mute status: NO FAULTS

Engine Control Module bus off status: NO FAULTS

Status of injection:

Injection post 4: Not active,

Injection post 3: Not active,

Post 2 injection: Not active,

Post 1 injection: Not active,

AFTER injection status: Off

Main injection: On

PRE injection status: On

Pilot injection: On

Lambda/Diesel Particulate Filter presence:

Lambda downstream probe: Present

Diesel Particulate Filter and upstream lambda probe: Present

Lambda upstream probe: Present

Diesel Particulate Filter: Present

Percentage of Diesel Particulate Filter soot mass: 26.47 %

Diesel Particulate Filter:

Diesel Particulate Filter clogged (forced regeneration needed): No

Filter overloaded - load level in range 4: No

Filter loaded - load level in range 3: No

Filter load normal - load level in range 2: No

Filter regenerated - load level in range 1: Yes

Diesel Particulate Filter broken (regeneration not possible): No

Particulate filter lamp:

Diesel Particulate Filter lamp activation due to flow resistance, distance from last manual RGN, oil viscosity: Off

Diesel Particulate Filter lamp activation due to flow resistance, number of suspended regeneration and driven distance from last DoorToDoor RGN: Off

lamp IOCP command (active diagnosis) - automatic cycle received: Off

lamp IOCP command (active diagnosis) - ON received: Off

lamp IOCP command (active diagnosis) - OFF received: Off

Diesel Particulate Filter lamp activation in ON mode during check test: No

Activation in ON mode due to number of regeneration interrupted by key off (after check test): Off

Activation ON (after check test) due to soot value too high: Off

Diesel Particulate Filter lamp activation in OFF mode (after check test): Yes

Result of Diesel Particulate Filter forced regeneration:

Forced regeneration state: Not active,

Diesel Particulate Filter regeneration activated and underway: Ended or not activated

Remaining percentage of not exhausted engine oil: 93.33 %

Water in fuel filter status:

Water in fuel filter lamp IOCP command (active diagnosis) - automatic cycle received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Water in fuel filter lamp IOCP command (active diagnosis) - OFF received: No

Water in fuel filter lamp due to sensor autotest at key ON: No

Water in fuel filter sensor in fault: No

Water in fuel filter present: No

Fuel filter heater:

Fuel filter heater command status: Off

Glow plug status:

Low voltage glow plug feedback: Correct

Glow plugs command : Cycle mode activation during IOLI mode: Off

Glow plugs command : OFF activation during IOLI mode: Off

Glow plugs command : ON activation during IOLI mode: Off

Feedback high voltage glow plugs: Active

Glow plugs command: On

Warm-Up status:

Warm Up status during this driving cycle: Not completed

Warm up activable status during current driving cycle: Yes

Engine Running: Yes

Warm up completed in the last driving cycle: Not completed

Maximum engine overspeed exceeding time counter: 1000.00 msec

ECU Time Stamps (RAM): 23690 min

ECU Time Stamps From Key On (RAM): 15 sec

Speed limiting (from proxi): 255 km/h

Engine oil viscosity odometer: 0.00 km

EGR valve duty cycle command: Opening

EGR high pressure valve control status:

Air quantity control: Enabled

EGR position control: Disabled

EGR valve learn: Disabled

Number of regenerations interrupted by key off: 0

Km travelled with DPF warning lamp 'on': 0

Mission profile in the engine life:

Engine life time: 342 min

Percentage of the mission profile A1: 0

Percentage of the mission profile B1: 1

Percentage of the mission profile C1: 50

Percentage of the mission profile D1: 13

Percentage of the mission profile E1: 17

Percentage of the mission profile F1: 0

Percentage of the mission profile G1: 6

Percentage of the mission profile H1: 0

Percentage of the mission profile I1: 0

Percentage of the mission profile L1: 6

Mission profile during the regeneration:

Engine life time: 224 min

Percentage of the mission profile A2: 0

Percentage of the mission profile B2: 6

Percentage of the mission profile C2: 59

Percentage of the mission profile D2: 17

Percentage of the mission profile E2: 4

Percentage of the mission profile F2: 0

Percentage of the mission profile G2: 1

Percentage of the mission profile H2: 0

Percentage of the mission profile I2: 0

Percentage of the mission profile L2: 10

Mission profile since last regeneration:

Engine life time: 138 min

Percentage of the mission profile A3: 0

Percentage of the mission profile B3: 0

Percentage of the mission profile C3: 22

Percentage of the mission profile D3: 8

Percentage of the mission profile E3: 51

Percentage of the mission profile F3: 0

Percentage of the mission profile G3: 11

Percentage of the mission profile H3: 0

Percentage of the mission profile I3: 0

Percentage of the mission profile L3: 3

Particulate filter regeneration: Off

Turbo control: Disabled

EGR valve control closed loop: Disabled

Lambda sensor status: Not active

Regeneration mode: High oxygen content

Glow plugs control status: Not active

Water In Fuel: Not present

Brake switch: Not pressed

Redundant Brake Switch Status: Not pressed

Clutch pedal: Not pressed

Fan command 1: Not activated

Fan command 2: Not activated

Fan command 3: Not activated

A/C Request: Off

Air Conditioner command: Off

Engine Control Module bus off status: NO FAULTS

Engine Control Module mute status: NO FAULTS

Body Control Module status: NO FAULTS

Braking System Module status: NO FAULTS

Manual Transmission Automated or Robotic Gear status: NO FAULTS

Pilot injection: Off

PRE injection status: Off

Main injection: Off

AFTER injection status: Off

POST 1 injection status: Off

POST 2 injection status: Off

POST 3 injection status: Off

POST 4 injection status: Off

Vehicle version:

With DPF and Lambda upstream sensor

With Lambda downstream sensor

Particulate filter state: 0% - 30%, Not clogged

DPF Lamp status:

IOCP command (active diagnosis) - ON received: No

IOCP command (active diagnosis) - automatic cycle received: No

DPF lamp activation via number of suspended rgn since last oil change: No

DPF lamp activation via distance since last manual procedure since last oil change: No

Activation OFF (after check test): Yes

Activation ON (after check test) due to soot value too high: No

Activation in ON mode due to number of regeneration interrupted by key off (after check test): No

Activation ON during check test: No

Priority command for activation in Blinking mode received (bit used only for MIL lamp): No

IOCP command (active diagnosis) - OFF received: No

Requested regeneration forced state of Diesel Particulate Filter:

Regeneration Status: Not active

Regeneration active with load level in range 2 (30% - 120%): Not active

Regeneration active with load level in range 3 (120% - 200%): Not active

Forced regeneration state: Not active

Engine oil change request: Off

Water in diesel filter: Not present

Water in fuel filter sensor in fault: No

Water in fuel filter lamp check at key ON: No

Water in fuel filter lamp IOCP command (active diagnosis) - OFF received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Fuel filter heater relay command: Off

Preheating control unit: Off

Feedback glow plugs high voltage: Off

ON activation during IOLI mode (only for high voltage): Off

OFF activation during IOLI mode (only for high voltage): Off

Cycle mode activation during IOLI mode (only for high voltage): Off

Low voltage glow plug feedback: Correct

Warm up completed in the last driving cycle: No

Engine Running: No

Warm up activable status during current driving cycle: No

Warm up completed in current driving cycle: No

Power latch duration: 6 msec

Engine status:

Failure warning lamp:

Lamp activation in OFF mode (after check test): No

Lamp activation in ON mode (after check test): No

Lamp activation in ON mode during check test: Yes

Lamp activation in BLINKING mode: No

Vehicle status: Still

Alternator status: Low

Key status: On

Engine status: Off

Crank Status: Off

Power Latch procedure activated: No

Power Latch status last cycle completed: Yes

Key ON before Power Latch completed: Yes

Top Travel Clutch pedal pressed: No

Accelerator pedal potentiometer 1 used: No

Accelerator pedal potentiometer 2 used: No

Accelerator Pedal Recovery: No

Main brake pedal pressed: No

Secondary brake pedal pressed: No

Brake pedal in fault: No

Extended travel clutch pedal pressed: No

Cruise switch: On

Cruise restore button (RCL): Released

Set cruise deceleration (-): Not requested

Set cruise acceleration (+): Not requested

Cruise control status: Active

Acceleration requested by cruise: Off

Tip up status: Off

Hold status: Off

Tip down status: Off

Deceleration requested by cruise: Off

Cruise disabled (temporary disable): On

Cruise disabled until end of trip: Off

Irreversible cruise error status:

Cruise lever error (invalid message from Body Control module on CAN): Not present

General system error: Not present

Reversible cruise deactivation: Cruise control switch

Alternator status: Not recharging

Gear engaged: Neutral

Transmission Self-Learning: Completed

Self-learning condition: Not plausible

Type of gearbox present: Mechanical

Conditioner enable request: Off

Conditioner relay control: Off

Air conditioner pressure first level reached: No

Air conditioner pressure last level reached: No

Air conditioner pressure sensor in fault: No

Output stage 1 FAN in fault: No

Output stage 2 FAN in fault: No

Engine coolant sensor in fault: No

Air conditioner compressor request: No

Output stage 1 FAN low speed command: No

Output stage 2 FAN high speed command: No

Cooling fan 1: Not active

Cooling fan 2: Not active

First speed FAN modality: Not active

Second speed FAN modality: Not active

Third speed FAN modality: Not active

Limited torque request from Brake System Module: Not active

Limited torque request from Transmission Control Module: Not active

Fuel pump relay command: Off

Crank Status: Off

Fuel pump relay command: OK

Throttle valve opening/closing sense: Negative

Throttle valve position control: Enabled

EGR check: Off

EGR in fault: No

Air flow sensor in fault: No

Error memory: Errors not present

Engine Oil Pressure Switch: pressure not present (switch closed)

Insufficient oil pressure with engine running: No

oil sensor in fault: No

Oil pressure lamp status: On

Engine oil level sensor initialization: Yes

Engine oil level sensor signal error: No

Engine oil level: 20% - 33%

Sensor Supply 1: Correct

Sensor Supply 2: Correct

Sensor Supply 3: Correct

Glow plugs lamp: Off

Engine oil lamp: Engine oil lamp activation ON during check test: Yes

Variable geometry turbo valve status: Not learnt

Phonic wheel synchronization status: Not synchronized

Engine speed sensor status: NO FAULTS

Speed limiter request by Body Control Module: No

Speed limiter control in stand by condition: Yes

Speed limiter control in activated condition: No

Speed limiter control in not actuable condition: No

Speed limiter control in override condition: No

Speed limiter control not available: No

Speed limiter buzzer activation: No

Reversible shut off of speed limiter by driver:

Override: No

VDC operation: No

Messages incoherence: No

Message counter SPEED_SETTING error: No

Irreversible shut off of speed limiter by driver function:

Shut off for acceleration pedal in fault: No

Shut off for vehicle speed sensor in fault: No

Message SPEED_SETTING absent: No

Counter of DPF lamp activation via soot load since last oil change: 0

Counter of DPF lamp activation via number of interrupted rgn since last oil change: 0

Counter of DPF lamp activation via distance since last manual procedure (DoorToDoor rgn) since last oil change: 0

Number of gear shift suggested by Gear Shift Indicator: 38929

Number of gear shift executed by driver: 8421

Engine stop causes:

Engine stop without any micro reset events: No

Engine stop after 5 consecutive micro reset events: No

Engine stop due to Manual Transmission Automated request (at low speed): No

Engine stop due to micro/HW supervisor error: No

Engine stop due to RAM/ROM level 2 test failed: No

Immobilizer Status:

Injection control unit: Programmed

Engine startup: Allowed

Universal code: Not enabled

Fast restart Function: Not active

Key code wrong (antenna/Key transponder wrong): No

Unknown code: No

No code received (CAN line not connected) or Timeout: No

Odometer: 17759.40 km

Odometer at last rewrite: 4219.00 km

Number of rewrites: 2

Number of overrevs: 19

Maximum engine speed: 4880 rpm

Maximum engine speed counter: 1000.00 msec

Last overrev odometer: 15657.10 km

Functioning time (eeprom): 23683 min

Time since Key-On (eeprom): 30 sec

Key On Counter (EEPROM): 1876

ECU Time first DTC detection (EEPROM): 0 min

ECU Time Stamps from KeyOn first DTC detection (EEPROM): 0 sec

Key-On counter alignment: Yes

Key-On counter alignment: 127

Low pressure EGR valve duty cycle command sign: Negative

Low pressure EGR valve air control enabled: Yes

Low pressure EGR valve position control enabled: No

Low pressure EGR valve offset learning procedure enabled or in progress: No

Low pressure EGR valve roller/cam link procedure enabled or in progress: No

Last DPF replacement odometer: 17759.40 km

Odometer from last DPF regeneration: 55.40 km

___________________________

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:09:59.576

___________________________

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:09:59.643

Average temperature of last 5 regenerations: 79.90 °C

full licienced version android

___________________________

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:00:07.428

EGR high pressure valve duty cycle command:

EGR high pressure valve opening/closing sense: Opening

DEVICE INFO:

Fiat drawing number: 55271527

VMI:

VDS:

VIS:

Hardware number: MJ9DFHW000

Hardware version: 00

Software number: 4L43A128

Software version: 0028

Homologation number: 9DF.A1

ISO code: 0001500814

SINCOM:

Factory:

Serial No:

VIN - Original:

ECU Time Stamps (RAM): 23683.00 min

ECU Time Stamps From Key On (RAM): 45.00 sec

Speed limiter omologation: 255.00 km/h

Driven distance too low viscosity recognition: 0.00 km

EGR high pressure valve duty cycle command:

EGR high pressure valve opening/closing sense: Opening

EGR high pressure valve control status:

EGR high pressure valve offset learning: Disabled

EGR high pressure valve position control: Disabled

EGR high pressure valve air quantity control: Enabled

EGR high pressure valve last offset learnt: 0.00 mm

Number of consecutive interrupted regenerations by key off: 0.00

Driven distance since Diesel Particulate Filter lamp ON: 0.00 km

Mission profile in the engine life:

Engine life time: 342.00 H

A1 Hill: 0.00 %

B1 Fast Highway: 1.00 %

C1 Extra Urban: 50.00 %

D1 City: 13.00 %

E1 Heavy Urban: 17.00 %

F1 Highway WarmUp: 0.00 %

G1 Extra Urban Engine Cold: 6.00 %

H1 Extreme Cold Engine: 0.00 %

I1 Cut-off: 0.00 %

L1 DTD - Hot: 6.00 %

Percentage of the mission profile M1: 2.00 %

Mission profile during Diesel Particulate Filter regeneration:

Engine life time: 224.00 min

A2 Hill: 0.00 %

B2 Fast Highway: 6.00 %

C2 Extra Urban: 59.00 %

D2 City: 17.00 %

E2 Heavy Urban: 4.00 %

F2 Highway WarmUp: 0.00 %

G2 Extra Urban Engine Cold: 1.00 %

H1 Extreme Cold Engine: 0.00 %

I2 Cut-off: 0.00 %

L2 DTD - Hot: 10.00 %

M2: 0.00 %

Mission profile since last Diesel Particulate Filter regeneration:

Engine life time: 132.00 min

A3 Hill: 0.00 %

B3 Fast Highway: 0.00 %

C3 Extra Urban: 23.00 %

D3 City: 8.00 %

E3 Heavy Urban: 50.00 %

F3 Highway WarmUp: 0.00 %

G3 Extra Urban Engine Cold: 11.00 %

H2 Extreme Cold Engine: 0.00 %

I3 Cut-off: 0.00 %

L3 DTD - Hot: 3.00 %

M3: 1.00 %

Engine condition status 1:

Water In Fuel: Not present

Glow plugs activated: Yes

DPF Regeneration mode: High oxygen concentration

Lambda upstream probe status: Not active,

EGR high pressure cooler bypass (exhaust gas cooled): Off

EGR high pressure valve control closed loop: Disabled

Boost control closed loop: Not active,

Particulate filter regeneration: Off

Key On Counter (EEPROM): 23683.00 min

CAN Communication Status:

Manual Trasmission Automated or Robotic Gear status: NO FAULTS

Braking System Module status: NO FAULTS

Body Control Module status: NO FAULTS

Engine Control Module mute status: NO FAULTS

Engine Control Module bus off status: NO FAULTS

Status of injection:

Injection post 4: Not active,

Injection post 3: Not active,

Post 2 injection: Not active,

Post 1 injection: Not active,

AFTER injection status: Off

Main injection: On

PRE injection status: On

Pilot injection: On

Lambda/Diesel Particulate Filter presence:

Lambda downstream probe: Present

Diesel Particulate Filter and upstream lambda probe: Present

Lambda upstream probe: Present

Diesel Particulate Filter: Present

Percentage of Diesel Particulate Filter soot mass: 26.47 %

Diesel Particulate Filter:

Diesel Particulate Filter clogged (forced regeneration needed): No

Filter overloaded - load level in range 4: No

Filter loaded - load level in range 3: No

Filter load normal - load level in range 2: No

Filter regenerated - load level in range 1: Yes

Diesel Particulate Filter broken (regeneration not possible): No

Particulate filter lamp:

Diesel Particulate Filter lamp activation due to flow resistance, distance from last manual RGN, oil viscosity: Off

Diesel Particulate Filter lamp activation due to flow resistance, number of suspended regeneration and driven distance from last DoorToDoor RGN: Off

lamp IOCP command (active diagnosis) - automatic cycle received: Off

lamp IOCP command (active diagnosis) - ON received: Off

lamp IOCP command (active diagnosis) - OFF received: Off

Diesel Particulate Filter lamp activation in ON mode during check test: No

Activation in ON mode due to number of regeneration interrupted by key off (after check test): Off

Activation ON (after check test) due to soot value too high: Off

Diesel Particulate Filter lamp activation in OFF mode (after check test): Yes

Result of Diesel Particulate Filter forced regeneration:

Forced regeneration state: Not active,

Diesel Particulate Filter regeneration activated and underway: Ended or not activated

Remaining percentage of not exhausted engine oil: 93.33 %

Water in fuel filter status:

Water in fuel filter lamp IOCP command (active diagnosis) - automatic cycle received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Water in fuel filter lamp IOCP command (active diagnosis) - OFF received: No

Water in fuel filter lamp due to sensor autotest at key ON: No

Water in fuel filter sensor in fault: No

Water in fuel filter present: No

Fuel filter heater:

Fuel filter heater command status: Off

Glow plug status:

Low voltage glow plug feedback: Correct

Glow plugs command : Cycle mode activation during IOLI mode: Off

Glow plugs command : OFF activation during IOLI mode: Off

Glow plugs command : ON activation during IOLI mode: Off

Feedback high voltage glow plugs: Active

Glow plugs command: On

Warm-Up status:

Warm Up status during this driving cycle: Not completed

Warm up activable status during current driving cycle: Yes

Engine Running: Yes

Warm up completed in the last driving cycle: Not completed

Maximum engine overspeed exceeding time counter: 1000.00 msec

ECU Time Stamps (RAM): 23690 min

ECU Time Stamps From Key On (RAM): 15 sec

Speed limiting (from proxi): 255 km/h

Engine oil viscosity odometer: 0.00 km

EGR valve duty cycle command: Opening

EGR high pressure valve control status:

Air quantity control: Enabled

EGR position control: Disabled

EGR valve learn: Disabled

Number of regenerations interrupted by key off: 0

Km travelled with DPF warning lamp 'on': 0

Mission profile in the engine life:

Engine life time: 342 min

Percentage of the mission profile A1: 0

Percentage of the mission profile B1: 1

Percentage of the mission profile C1: 50

Percentage of the mission profile D1: 13

Percentage of the mission profile E1: 17

Percentage of the mission profile F1: 0

Percentage of the mission profile G1: 6

Percentage of the mission profile H1: 0

Percentage of the mission profile I1: 0

Percentage of the mission profile L1: 6

Mission profile during the regeneration:

Engine life time: 224 min

Percentage of the mission profile A2: 0

Percentage of the mission profile B2: 6

Percentage of the mission profile C2: 59

Percentage of the mission profile D2: 17

Percentage of the mission profile E2: 4

Percentage of the mission profile F2: 0

Percentage of the mission profile G2: 1

Percentage of the mission profile H2: 0

Percentage of the mission profile I2: 0

Percentage of the mission profile L2: 10

Mission profile since last regeneration:

Engine life time: 138 min

Percentage of the mission profile A3: 0

Percentage of the mission profile B3: 0

Percentage of the mission profile C3: 22

Percentage of the mission profile D3: 8

Percentage of the mission profile E3: 51

Percentage of the mission profile F3: 0

Percentage of the mission profile G3: 11

Percentage of the mission profile H3: 0

Percentage of the mission profile I3: 0

Percentage of the mission profile L3: 3

Particulate filter regeneration: Off

Turbo control: Disabled

EGR valve control closed loop: Disabled

Lambda sensor status: Not active

Regeneration mode: High oxygen content

Glow plugs control status: Not active

Water In Fuel: Not present

Brake switch: Not pressed

Redundant Brake Switch Status: Not pressed

Clutch pedal: Not pressed

Fan command 1: Not activated

Fan command 2: Not activated

Fan command 3: Not activated

A/C Request: Off

Air Conditioner command: Off

Engine Control Module bus off status: NO FAULTS

Engine Control Module mute status: NO FAULTS

Body Control Module status: NO FAULTS

Braking System Module status: NO FAULTS

Manual Transmission Automated or Robotic Gear status: NO FAULTS

Pilot injection: Off

PRE injection status: Off

Main injection: Off

AFTER injection status: Off

POST 1 injection status: Off

POST 2 injection status: Off

POST 3 injection status: Off

POST 4 injection status: Off

Vehicle version:

With DPF and Lambda upstream sensor

With Lambda downstream sensor

Particulate filter state: 0% - 30%, Not clogged

DPF Lamp status:

IOCP command (active diagnosis) - ON received: No

IOCP command (active diagnosis) - automatic cycle received: No

DPF lamp activation via number of suspended rgn since last oil change: No

DPF lamp activation via distance since last manual procedure since last oil change: No

Activation OFF (after check test): Yes

Activation ON (after check test) due to soot value too high: No

Activation in ON mode due to number of regeneration interrupted by key off (after check test): No

Activation ON during check test: No

Priority command for activation in Blinking mode received (bit used only for MIL lamp): No

IOCP command (active diagnosis) - OFF received: No

Requested regeneration forced state of Diesel Particulate Filter:

Regeneration Status: Not active

Regeneration active with load level in range 2 (30% - 120%): Not active

Regeneration active with load level in range 3 (120% - 200%): Not active

Forced regeneration state: Not active

Engine oil change request: Off

Water in diesel filter: Not present

Water in fuel filter sensor in fault: No

Water in fuel filter lamp check at key ON: No

Water in fuel filter lamp IOCP command (active diagnosis) - OFF received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Water in fuel filter lamp IOCP command (active diagnosis) - ON received: No

Fuel filter heater relay command: Off

Preheating control unit: Off

Feedback glow plugs high voltage: Off

ON activation during IOLI mode (only for high voltage): Off

OFF activation during IOLI mode (only for high voltage): Off

Cycle mode activation during IOLI mode (only for high voltage): Off

Low voltage glow plug feedback: Correct

Warm up completed in the last driving cycle: No

Engine Running: No

Warm up activable status during current driving cycle: No

Warm up completed in current driving cycle: No

Power latch duration: 6 msec

Engine status:

Failure warning lamp:

Lamp activation in OFF mode (after check test): No

Lamp activation in ON mode (after check test): No

Lamp activation in ON mode during check test: Yes

Lamp activation in BLINKING mode: No

Vehicle status: Still

Alternator status: Low

Key status: On

Engine status: Off

Crank Status: Off

Power Latch procedure activated: No

Power Latch status last cycle completed: Yes

Key ON before Power Latch completed: Yes

Top Travel Clutch pedal pressed: No

Accelerator pedal potentiometer 1 used: No

Accelerator pedal potentiometer 2 used: No

Accelerator Pedal Recovery: No

Main brake pedal pressed: No

Secondary brake pedal pressed: No

Brake pedal in fault: No

Extended travel clutch pedal pressed: No

Cruise switch: On

Cruise restore button (RCL): Released

Set cruise deceleration (-): Not requested

Set cruise acceleration (+): Not requested

Cruise control status: Active

Acceleration requested by cruise: Off

Tip up status: Off

Hold status: Off

Tip down status: Off

Deceleration requested by cruise: Off

Cruise disabled (temporary disable): On

Cruise disabled until end of trip: Off

Irreversible cruise error status:

Cruise lever error (invalid message from Body Control module on CAN): Not present

General system error: Not present

Reversible cruise deactivation: Cruise control switch

Alternator status: Not recharging

Gear engaged: Neutral

Transmission Self-Learning: Completed

Self-learning condition: Not plausible

Type of gearbox present: Mechanical

Conditioner enable request: Off

Conditioner relay control: Off

Air conditioner pressure first level reached: No

Air conditioner pressure last level reached: No

Air conditioner pressure sensor in fault: No

Output stage 1 FAN in fault: No

Output stage 2 FAN in fault: No

Engine coolant sensor in fault: No

Air conditioner compressor request: No

Output stage 1 FAN low speed command: No

Output stage 2 FAN high speed command: No

Cooling fan 1: Not active

Cooling fan 2: Not active

First speed FAN modality: Not active

Second speed FAN modality: Not active

Third speed FAN modality: Not active

Limited torque request from Brake System Module: Not active

Limited torque request from Transmission Control Module: Not active

Fuel pump relay command: Off

Crank Status: Off

Fuel pump relay command: OK

Throttle valve opening/closing sense: Negative

Throttle valve position control: Enabled

EGR check: Off

EGR in fault: No

Air flow sensor in fault: No

Error memory: Errors not present

Engine Oil Pressure Switch: pressure not present (switch closed)

Insufficient oil pressure with engine running: No

oil sensor in fault: No

Oil pressure lamp status: On

Engine oil level sensor initialization: Yes

Engine oil level sensor signal error: No

Engine oil level: 20% - 33%

Sensor Supply 1: Correct

Sensor Supply 2: Correct

Sensor Supply 3: Correct

Glow plugs lamp: Off

Engine oil lamp: Engine oil lamp activation ON during check test: Yes

Variable geometry turbo valve status: Not learnt

Phonic wheel synchronization status: Not synchronized

Engine speed sensor status: NO FAULTS

Speed limiter request by Body Control Module: No

Speed limiter control in stand by condition: Yes

Speed limiter control in activated condition: No

Speed limiter control in not actuable condition: No

Speed limiter control in override condition: No

Speed limiter control not available: No

Speed limiter buzzer activation: No

Reversible shut off of speed limiter by driver:

Override: No

VDC operation: No

Messages incoherence: No

Message counter SPEED_SETTING error: No

Irreversible shut off of speed limiter by driver function:

Shut off for acceleration pedal in fault: No

Shut off for vehicle speed sensor in fault: No

Message SPEED_SETTING absent: No

Counter of DPF lamp activation via soot load since last oil change: 0

Counter of DPF lamp activation via number of interrupted rgn since last oil change: 0

Counter of DPF lamp activation via distance since last manual procedure (DoorToDoor rgn) since last oil change: 0

Number of gear shift suggested by Gear Shift Indicator: 38929

Number of gear shift executed by driver: 8421

Engine stop causes:

Engine stop without any micro reset events: No

Engine stop after 5 consecutive micro reset events: No

Engine stop due to Manual Transmission Automated request (at low speed): No

Engine stop due to micro/HW supervisor error: No

Engine stop due to RAM/ROM level 2 test failed: No

Immobilizer Status:

Injection control unit: Programmed

Engine startup: Allowed

Universal code: Not enabled

Fast restart Function: Not active

Key code wrong (antenna/Key transponder wrong): No

Unknown code: No

No code received (CAN line not connected) or Timeout: No

Odometer: 17759.40 km

Odometer at last rewrite: 4219.00 km

Number of rewrites: 2

Number of overrevs: 19

Maximum engine speed: 4880 rpm

Maximum engine speed counter: 1000.00 msec

Last overrev odometer: 15657.10 km

Functioning time (eeprom): 23683 min

Time since Key-On (eeprom): 30 sec

Key On Counter (EEPROM): 1876

ECU Time first DTC detection (EEPROM): 0 min

ECU Time Stamps from KeyOn first DTC detection (EEPROM): 0 sec

Key-On counter alignment: Yes

Key-On counter alignment: 127

Low pressure EGR valve duty cycle command sign: Negative

Low pressure EGR valve air control enabled: Yes

Low pressure EGR valve position control enabled: No

Low pressure EGR valve offset learning procedure enabled or in progress: No

Low pressure EGR valve roller/cam link procedure enabled or in progress: No

Last DPF replacement odometer: 17759.40 km

Odometer from last DPF regeneration: 55.40 km

___________________________

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:09:59.576

___________________________

Tested device: Injection Diesel Marelli F1A 130HP Euro6

___________________

2024/01/17 16:09:59.643

Average temperature of last 5 regenerations: 79.90 °C