Scottieo321

Member

Hi guys,

I've got a very big issue with a 1.2 06 grande Punto timing.

Now before anyone asks I've been through all the guides on here and looked at quite a few threads to find out my issue but I'm all out of ideas.

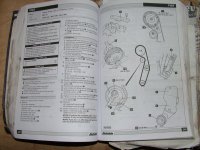

Changed the timing belt and pulley on Sunday gone (yes a whole week to do this). The cam and crank both have timing marks on them but the cam doesn't have one on the engine to put it to which isn't a big problem as I have the timing tools, so I put both to TDC but it's a struggle at points to manually turn the engine over (still turns but sort of has points where gets a little tough but still turns with not too much pressure on).

Now that aside get through the whole process everything remaining in time put all back together and it won't start, it tries but will not go at all. So I thought ok maybe it's actually 180 out from the last person (bearing in mind this has been messed on with before me) so tried and same results. Now if I put either crank or cam just past TDC then it turns over perfectly fine by hand but again won't start (obviously) also might I add no matter what I've got oil sorted of spitting out of the few holes dotted round which I'm guessing is just a build up of pressure turning it over (all sparks are removed and in good condition only few months old).

I know there's a few different engines for this one but just wondering if anyone has ran into this issue before and if they were able to rectify it and get the car running again. This has had my head bashed in for days and no matter what I seem to do it will not start (well it did once and had smoke coming out exhaust then misfired and cut out ) .

Please any help is appreciated

Thank you.

I've got a very big issue with a 1.2 06 grande Punto timing.

Now before anyone asks I've been through all the guides on here and looked at quite a few threads to find out my issue but I'm all out of ideas.

Changed the timing belt and pulley on Sunday gone (yes a whole week to do this). The cam and crank both have timing marks on them but the cam doesn't have one on the engine to put it to which isn't a big problem as I have the timing tools, so I put both to TDC but it's a struggle at points to manually turn the engine over (still turns but sort of has points where gets a little tough but still turns with not too much pressure on).

Now that aside get through the whole process everything remaining in time put all back together and it won't start, it tries but will not go at all. So I thought ok maybe it's actually 180 out from the last person (bearing in mind this has been messed on with before me) so tried and same results. Now if I put either crank or cam just past TDC then it turns over perfectly fine by hand but again won't start (obviously) also might I add no matter what I've got oil sorted of spitting out of the few holes dotted round which I'm guessing is just a build up of pressure turning it over (all sparks are removed and in good condition only few months old).

I know there's a few different engines for this one but just wondering if anyone has ran into this issue before and if they were able to rectify it and get the car running again. This has had my head bashed in for days and no matter what I seem to do it will not start (well it did once and had smoke coming out exhaust then misfired and cut out ) .

Please any help is appreciated

Thank you.

- Year

- 2006