KurtVerbose

Member

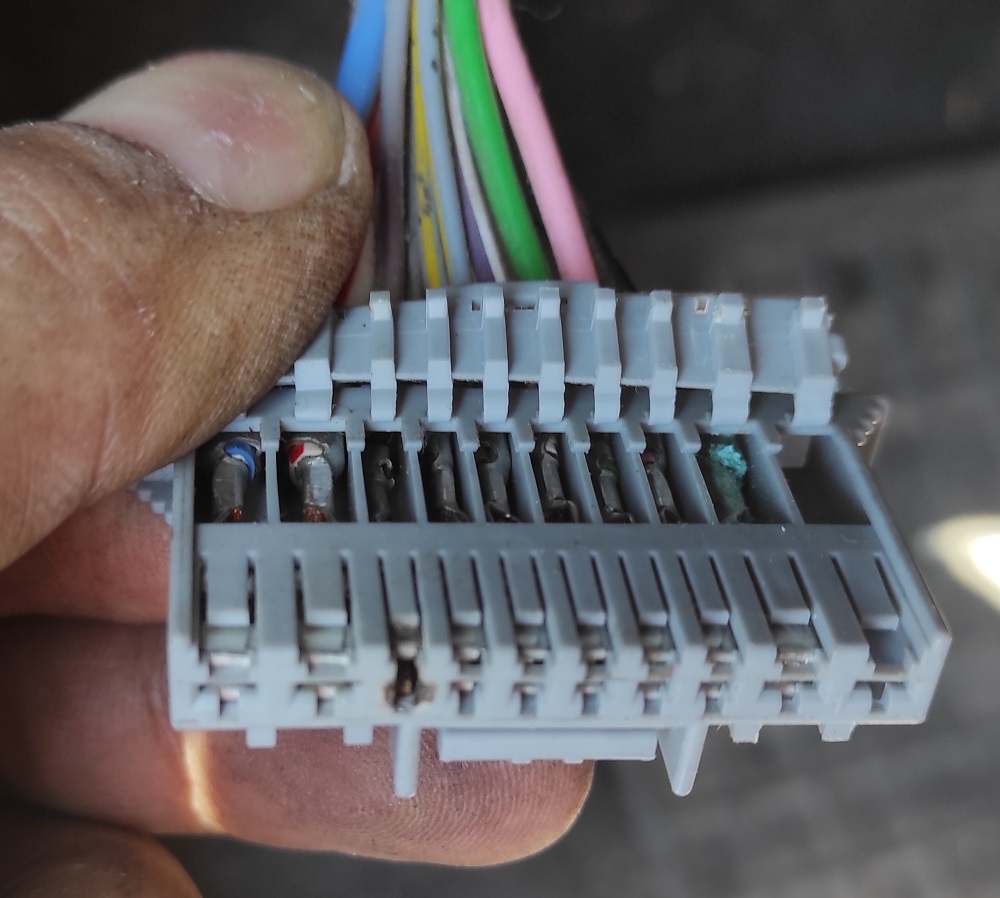

So I noticed that one of the dipped beams on our Panda wasn't working. Changing the bulb didn't fix it and I noticed that the connector was a bit melted and charred.

I checked the other one and although it was working it was so much worse that it fell apart as I took it out.

So I did a bit of research and found out about the block connector issue and pulled it out. One connector was a bit charred, but I've seen worse on the internet.

So I've removed the lamps as they will need new block connectors (which I've ordered), and I've ordered a new block connector. Just wondering if that's the route cause of the problem. It's quite a palaver getting all this done so I don't want to do it twice.

The other thing I don't really understand is the revised block connector has thicker wires, but you still join it onto the original thinner wires. Doesn't that just shift the problem?

By the way, bulbs are standard. Don't know if they always have been. Maybe someone in the past put brighter bulbs in? Fuses are ok.

All suggestions and feedback gratefully appreciated!

I checked the other one and although it was working it was so much worse that it fell apart as I took it out.

So I did a bit of research and found out about the block connector issue and pulled it out. One connector was a bit charred, but I've seen worse on the internet.

So I've removed the lamps as they will need new block connectors (which I've ordered), and I've ordered a new block connector. Just wondering if that's the route cause of the problem. It's quite a palaver getting all this done so I don't want to do it twice.

The other thing I don't really understand is the revised block connector has thicker wires, but you still join it onto the original thinner wires. Doesn't that just shift the problem?

By the way, bulbs are standard. Don't know if they always have been. Maybe someone in the past put brighter bulbs in? Fuses are ok.

All suggestions and feedback gratefully appreciated!