Hi All

First post here on this great forum, I am a member of many other forums for Mercedes, Audi's, Range Rover VW, but today I picked up a little bargin ! hence why I have decided to join !

I have just bought a great little Fiat 500, year 2009, 1.2L in white, it has 80K miles and I bought her for £700!! it has a years MOT too.

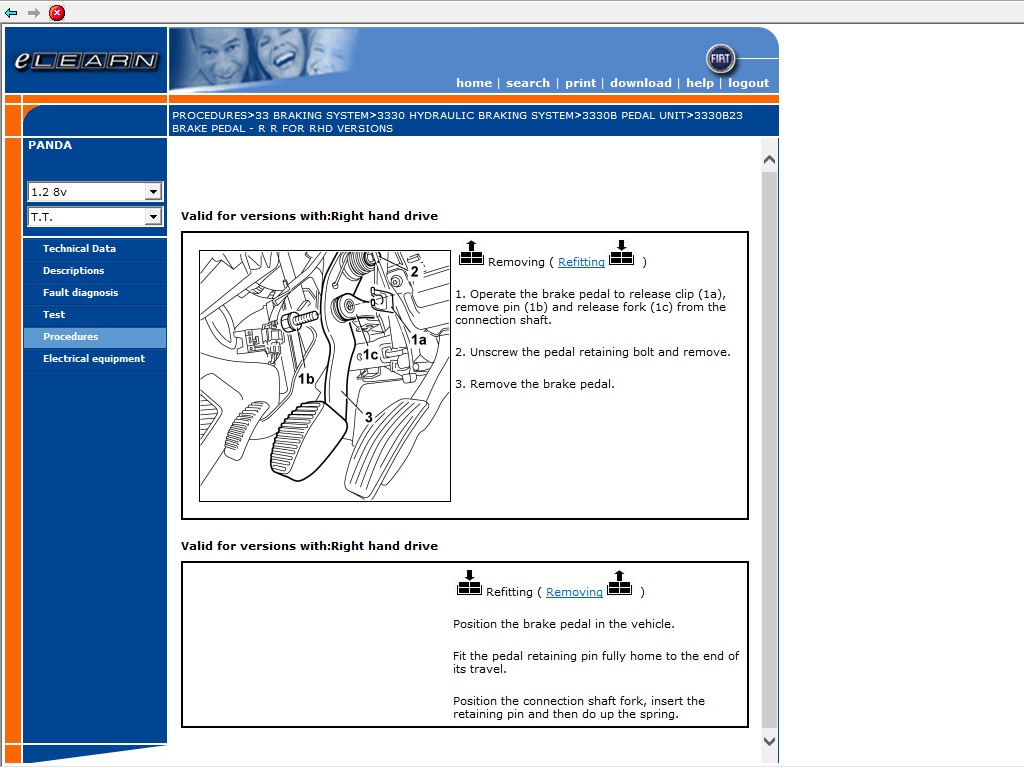

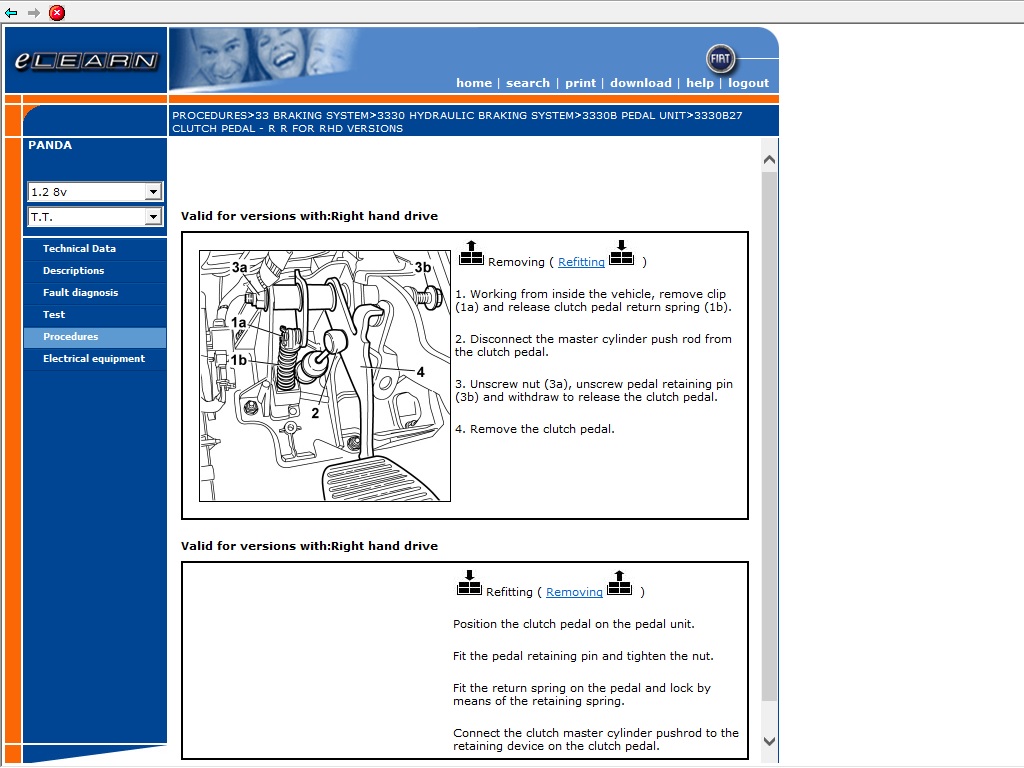

I have noticed that the clutch pedal has snapped at the welds a the pivot bar at the top, to which I believe is a very common fault on these cars along with Fiat Panda's.

I am therefore looking at replacing the clutch pedal, I pay try and weld myself or just buy another.

I found two great info sheets on this forum on the clutch pedal removal, but just wanted to know if anyone has done the job and to gain any tips?

Thanks in advance.

First post here on this great forum, I am a member of many other forums for Mercedes, Audi's, Range Rover VW, but today I picked up a little bargin ! hence why I have decided to join !

I have just bought a great little Fiat 500, year 2009, 1.2L in white, it has 80K miles and I bought her for £700!! it has a years MOT too.

I have noticed that the clutch pedal has snapped at the welds a the pivot bar at the top, to which I believe is a very common fault on these cars along with Fiat Panda's.

I am therefore looking at replacing the clutch pedal, I pay try and weld myself or just buy another.

I found two great info sheets on this forum on the clutch pedal removal, but just wanted to know if anyone has done the job and to gain any tips?

Thanks in advance.