As suggested by Koalar, I backed the bolts about 2.5mm from the flywheel and there is some clutch pedal travel but I guess I will find out if enough to operate the clutch when the car is assembled again. Also who knows what those bolts are torqued to now

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Clutch pedal not working after clutch replacement.

- Thread starter Jdazz

- Start date

Currently reading:

Technical Clutch pedal not working after clutch replacement.

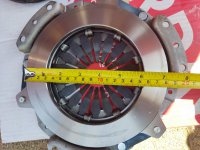

Clutch kits and the original.

At first I thought it was the difference in the spring diaphragm that was the problem.

At first I thought it was the difference in the spring diaphragm that was the problem.

Attachments

-

Screenshot_2023-04-15-09-09-56-789_org.thoughtcrime.securesms.jpg941.3 KB · Views: 51

Screenshot_2023-04-15-09-09-56-789_org.thoughtcrime.securesms.jpg941.3 KB · Views: 51 -

IMG_20230416_224259.jpg6 MB · Views: 55

IMG_20230416_224259.jpg6 MB · Views: 55 -

IMG_20230417_002654.jpg5.8 MB · Views: 56

IMG_20230417_002654.jpg5.8 MB · Views: 56 -

IMG_20230416_224447.jpg5 MB · Views: 47

IMG_20230416_224447.jpg5 MB · Views: 47 -

Screenshot_2023-04-17-00-22-14-867_com.miui.gallery.jpg1.9 MB · Views: 58

Screenshot_2023-04-17-00-22-14-867_com.miui.gallery.jpg1.9 MB · Views: 58 -

IMG_20230527_102247.jpg2.7 MB · Views: 70

IMG_20230527_102247.jpg2.7 MB · Views: 70

Trans mech clutch kit.

About 6mm gap between pressure plate and flywheel without being bolted, just resting on it.

About 6mm gap between pressure plate and flywheel without being bolted, just resting on it.

Attachments

-

IMG_20230527_113512.jpg1.3 MB · Views: 62

IMG_20230527_113512.jpg1.3 MB · Views: 62 -

IMG_20230527_103644.jpg5.4 MB · Views: 54

IMG_20230527_103644.jpg5.4 MB · Views: 54 -

IMG_20230527_103627.jpg5.5 MB · Views: 50

IMG_20230527_103627.jpg5.5 MB · Views: 50 -

IMG_20230527_103150.jpg4.9 MB · Views: 53

IMG_20230527_103150.jpg4.9 MB · Views: 53 -

IMG_20230527_103126.jpg3.9 MB · Views: 53

IMG_20230527_103126.jpg3.9 MB · Views: 53 -

IMG_20230527_103103.jpg5.5 MB · Views: 56

IMG_20230527_103103.jpg5.5 MB · Views: 56 -

IMG_20230527_102753.jpg1.7 MB · Views: 53

IMG_20230527_102753.jpg1.7 MB · Views: 53 -

IMG_20230527_102424.jpg5.1 MB · Views: 58

IMG_20230527_102424.jpg5.1 MB · Views: 58 -

IMG_20230527_101753.jpg1.1 MB · Views: 46

IMG_20230527_101753.jpg1.1 MB · Views: 46 -

IMG_20230527_101650.jpg1.1 MB · Views: 53

IMG_20230527_101650.jpg1.1 MB · Views: 53

Nope I think you miss understood meAs suggested by Koalar, I backed the bolts about 2.5mm from the flywheel and there is some clutch pedal travel but I guess I will find out if enough to operate the clutch when the car is assembled again. Also who knows what those bolts are torqued to now

A very bad idea

Valeo clutch kit.

About 5mm gap between pressure plate and flywheel without being bolted, just resting on it.

About 5mm gap between pressure plate and flywheel without being bolted, just resting on it.

Attachments

-

IMG_20230527_104927.jpg1.9 MB · Views: 44

IMG_20230527_104927.jpg1.9 MB · Views: 44 -

IMG_20230527_104857.jpg1.9 MB · Views: 68

IMG_20230527_104857.jpg1.9 MB · Views: 68 -

IMG_20230527_104739.jpg1.9 MB · Views: 45

IMG_20230527_104739.jpg1.9 MB · Views: 45 -

IMG_20230527_104511.jpg2.1 MB · Views: 55

IMG_20230527_104511.jpg2.1 MB · Views: 55 -

IMG_20230527_104122.jpg4.2 MB · Views: 49

IMG_20230527_104122.jpg4.2 MB · Views: 49 -

IMG_20230527_104038.jpg4.6 MB · Views: 51

IMG_20230527_104038.jpg4.6 MB · Views: 51 -

IMG_20230527_103920.jpg5.5 MB · Views: 89

IMG_20230527_103920.jpg5.5 MB · Views: 89 -

IMG_20230527_103912.jpg5.3 MB · Views: 48

IMG_20230527_103912.jpg5.3 MB · Views: 48

Ridex clutch kit.

About 4mm gap between pressure plate and flywheel without being bolted, just resting on it.

About 4mm gap between pressure plate and flywheel without being bolted, just resting on it.

Attachments

-

IMG_20230527_110320.jpg1.2 MB · Views: 52

IMG_20230527_110320.jpg1.2 MB · Views: 52 -

IMG_20230527_110259.jpg1.4 MB · Views: 45

IMG_20230527_110259.jpg1.4 MB · Views: 45 -

IMG_20230527_110042.jpg1.6 MB · Views: 44

IMG_20230527_110042.jpg1.6 MB · Views: 44 -

IMG_20230527_105735.jpg5.8 MB · Views: 45

IMG_20230527_105735.jpg5.8 MB · Views: 45 -

IMG_20230527_105611.jpg6 MB · Views: 50

IMG_20230527_105611.jpg6 MB · Views: 50 -

IMG_20230527_105503.jpg5 MB · Views: 50

IMG_20230527_105503.jpg5 MB · Views: 50 -

IMG_20230527_105436.jpg5.6 MB · Views: 56

IMG_20230527_105436.jpg5.6 MB · Views: 56 -

IMG_20230527_110404.jpg1.5 MB · Views: 47

IMG_20230527_110404.jpg1.5 MB · Views: 47

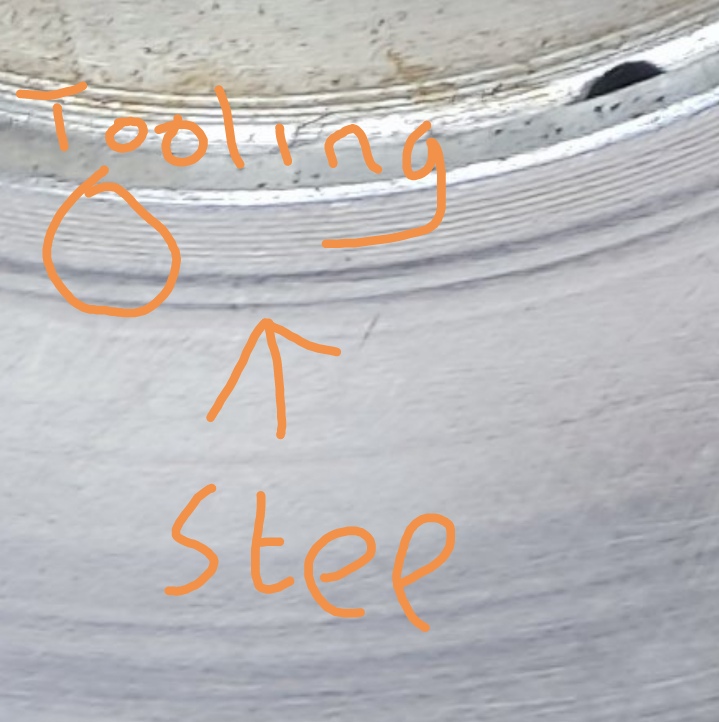

Your flywheel has a groove down the drive surface?

Mine bottom image

Original fiat AP clutch kit.

Shown with transmech and Ridex friction plates. Valeo friction plate does not fit with the AP pressure plate.

Shown with transmech and Ridex friction plates. Valeo friction plate does not fit with the AP pressure plate.

Attachments

-

IMG_20230527_111725.jpg2 MB · Views: 87

IMG_20230527_111725.jpg2 MB · Views: 87 -

IMG_20230527_111709.jpg1.7 MB · Views: 43

IMG_20230527_111709.jpg1.7 MB · Views: 43 -

IMG_20230527_111459_1.jpg3.9 MB · Views: 54

IMG_20230527_111459_1.jpg3.9 MB · Views: 54 -

IMG_20230527_111459.jpg5.9 MB · Views: 50

IMG_20230527_111459.jpg5.9 MB · Views: 50 -

IMG_20230527_111437.jpg5.8 MB · Views: 46

IMG_20230527_111437.jpg5.8 MB · Views: 46 -

IMG_20230527_111352.jpg6.4 MB · Views: 53

IMG_20230527_111352.jpg6.4 MB · Views: 53 -

IMG_20230527_111329.jpg5.8 MB · Views: 53

IMG_20230527_111329.jpg5.8 MB · Views: 53 -

IMG_20230527_111923.jpg5.1 MB · Views: 56

IMG_20230527_111923.jpg5.1 MB · Views: 56 -

IMG_20230527_112258.jpg2.1 MB · Views: 46

IMG_20230527_112258.jpg2.1 MB · Views: 46 -

IMG_20230527_112524.jpg5.7 MB · Views: 44

IMG_20230527_112524.jpg5.7 MB · Views: 44 -

IMG_20230527_112859.jpg2 MB · Views: 51

IMG_20230527_112859.jpg2 MB · Views: 51

Yours looks flat all the way probably because your car runs a 200mm friction plateView attachment 424222View attachment 424223

Your flywheel has a groove down the drive surface?

Mine bottom image

Mine runs a 180mm, so I guess it has bedded itself in.

Yours looks flat all the way probably because your car runs a 200mm friction plateView attachment 424222View attachment 424223

Your flywheel has a groove down the drive surface?

Mine bottom image

Mine runs a 180mm, so I guess it has bedded itself in

The transmech looks a bit different the others are pretty much the same. When I measured them with the calipers they are all the same size.Did all the release bearing you got with the kits look identical?

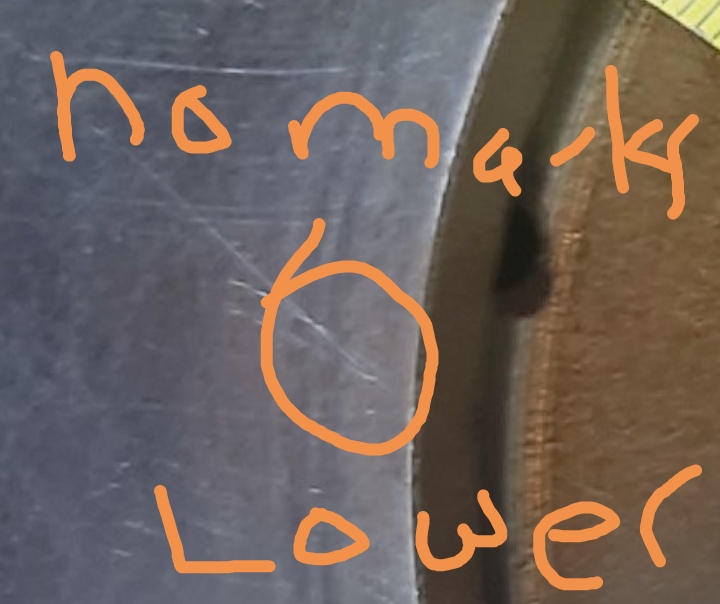

How can the drive plate sit flat

The flywheel is worn lower at different points

It's a bit more than bedding in looking at the photos, but I am not there

The photo of mine is the wear at 100K miles

The flywheel is worn lower at different points

It's a bit more than bedding in looking at the photos, but I am not there

The photo of mine is the wear at 100K miles

The friction plate sits completely flat on on the flywheel, the marks you highlighted are very superficial. I actually took the flywheel to a machining shop as it was a bit glassed and the guy there told me to save the money, took a bit of emery cloth and right in front of me started running the glassing off of it. Gave the emery cloth to take home as wellHow can the drive plate sit flat

The flywheel is worn lower at different points

It's a bit more than bedding in looking at the photos, but I am not there

The photo of mine is the wear at 100K milesView attachment 424245View attachment 424246

So now my question is, is the step the reason the pressure plate doesn't sit flat?

My car is at 102k miles.How can the drive plate sit flat

The flywheel is worn lower at different points

It's a bit more than bedding in looking at the photos, but I am not there

The photo of mine is the wear at 100K milesView attachment 424245View attachment 424246

- Joined

- Sep 14, 2009

- Messages

- 19,899

- Points

- 3,413

A 4mm gap under pressure plate is about what I had on 100HP and diesel. Tightening the screws pulls in down and slightly reduces the spring fingers angle. Make 100% sure the dowels are correctly located. They will cause the plate to sit high and/or unevenly if they don't locate properly.

I repeat it is not correctA 4mm gap under pressure plate is about what I had on 100HP and diesel. Tightening the screws pulls in down and slightly reduces the spring fingers angle. Make 100% sure the dowels are correctly located. They will cause the plate to sit high and/or unevenly if they don't locate properly.

the original posters has already posted a picture of the fingers disappearing when the pressure plate is tightened

I can not emphasise enough that until this is sorted it a waste of time lifting the gearbox in and out

It has to be one or more, flywheel, drive plate or pressure plate, either wrong part or damaged part. Which is what we are trying to sort,

Here a copy of the OP photo

Saying everything is normal is not perticulary helpful

Hi Dave,A 4mm gap under pressure plate is about what I had on 100HP and diesel. Tightening the screws pulls in down and slightly reduces the spring fingers angle. Make 100% sure the dowels are correctly located. They will cause the plate to sit high and/or unevenly if they don't locate properly.

the dowels have not been removed, also without the friction plate the pressure plate sits flat against the flywheel.

My car is a 1.2 Dynamic with a petrol engine, year 2004.

Thank you for the suggestion.

You need to put a dial test indicator on itThe friction plate sits completely flat on on the flywheel, the marks you highlighted are very superficial. I actually took the flywheel to a machining shop as it was a bit glassed and the guy there told me to save the money, took a bit of emery cloth and right in front of me started running the glassing off of it. Gave the emery cloth to take home as well

So now my question is, is the step the reason the pressure plate doesn't sit flat?

I don't have the fiat spec but normally it's less than 0.004" it looks like it's going to be more than that to me.

What ever is skimmed off the matting surface has to so be removed from the bolt face also

Too much run out and you end up burning out the new clutch and/or judder

I don't think it's the only problem.

Right let's start at the begining

The original clutch was working and slave didnt break until you changed the clutch

If you put the original drive plate and pressure plate back the fingers still bend flat

The only thing that's been altered is the flywheel has been off and put back

Try removing the flywheel and try without the centre bolts and ring

Be easer to see what's happening on the bench Anyhow