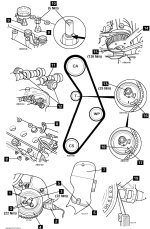

Installation

1. Hold camshaft sprocket. Use tool No 1860831000 [14].

2. Slacken camshaft sprocket bolt [15]

3. Ensure piston position tools fitted correctly into cylinders No.1 & No.2 [9].

& Ensure locking tools fitted correctly to each camshaft [12].

5 Fit timing belt in anti-clockwise direction, starting at crankshaft sprocket Ensure belt is taut between sprockets on non-tensioned side.

6. Turn tensioner pulley until mark at maximum tension position [16]. Use tool No. 1860987000

7. Tighten tensioner nut to 25 Nm [13]

8. Hold camshaft sprocket. Use tool No 1860831000 [14].

9. Tighten camshaft sprocket bolt to 120 Nm [15j

10. Remove locking tools from camshafts [12] Remove piston position tools [9]

11. Turn crankshaft two turns clockwise to setting position

12. Temporarily refit crankshaft pulley Check alignment of dowel pin opposite crankshaft position (CKP) sensor [1]

13. Slacken tensioner nut [13].

14 Turn tensioner pulley until marks aligned [17] & [18] Use tool No. 1860987000

15 Tighten tensioner nut to 25 Nm [13].

16. Turn crankshaft two turns clockwise to setting position.

17. Screw piston position tools into cylinders No.1 & No.2 [9] Tool No. 1860992000. Tightening torque: 5 Nm.

18. Turn crankshaft slightly until notches of both tools aligned with upper surface [10].

19. Ensure slots in camshafts are aligned with blanking plug holes [11]

20. Ensure locking tools fit easily to each camshaft [12]. If not: Repeat installation and tensioning procedures.

21. Install components in reverse order of removal

22. Tighten crankshaft pulley bolts [3]. Tightening torque: 22 Nm

23. Ensure crankshaft position (CKP) sensor air gap is 0.5-1,5 mm [19].

Stains Addition

24. turn engine 2 complete crank revolutions, in direction of rotation, BY HAND before starting with the key to ensure it will turn 'freely'.