The big breather hose is the thin one, from under the air box, to the base of the plastic inlet manifold. It provides vaccum to extract fumes from the crank case. This one is goosed.

I find the standard hose a bit short, to the extent it pulls off when you touch the air box, and is not long enough to allow you turn the air box over without removing it, or to see to attach it again. As the hose on my car has cracked and split I decided to change it and extend it a little to alleviate the above issues.

Tools needed and equipment

1. Remove the air intake spout

2. Remove the two 10mm bolts that secure the air box and carefully lift the air box off the throttle body and back mount.

Lift straight up to avoid straining or breaking the back mounting.

3. Remove the clip attaching the crank case breather hose to the spiggot on the cam cover and pull the hose away

4. Remove air box and put aside.

5. Pull the big breather hose off the air box. (Its the little pipe)

4 Pull the thin hose from the copper spiggot under the air box so its now free and ready for removal at its lower end where it fixes to the inlet manifold.

At this point I decided to remove the battery as the hose lower fitting was very tight and hard to pull off, even though there are no hose clips. If you are able to reach down the back of the engine without extra space thats good. I recommend you wear a glove to protect your hand from knocks and scratches though.

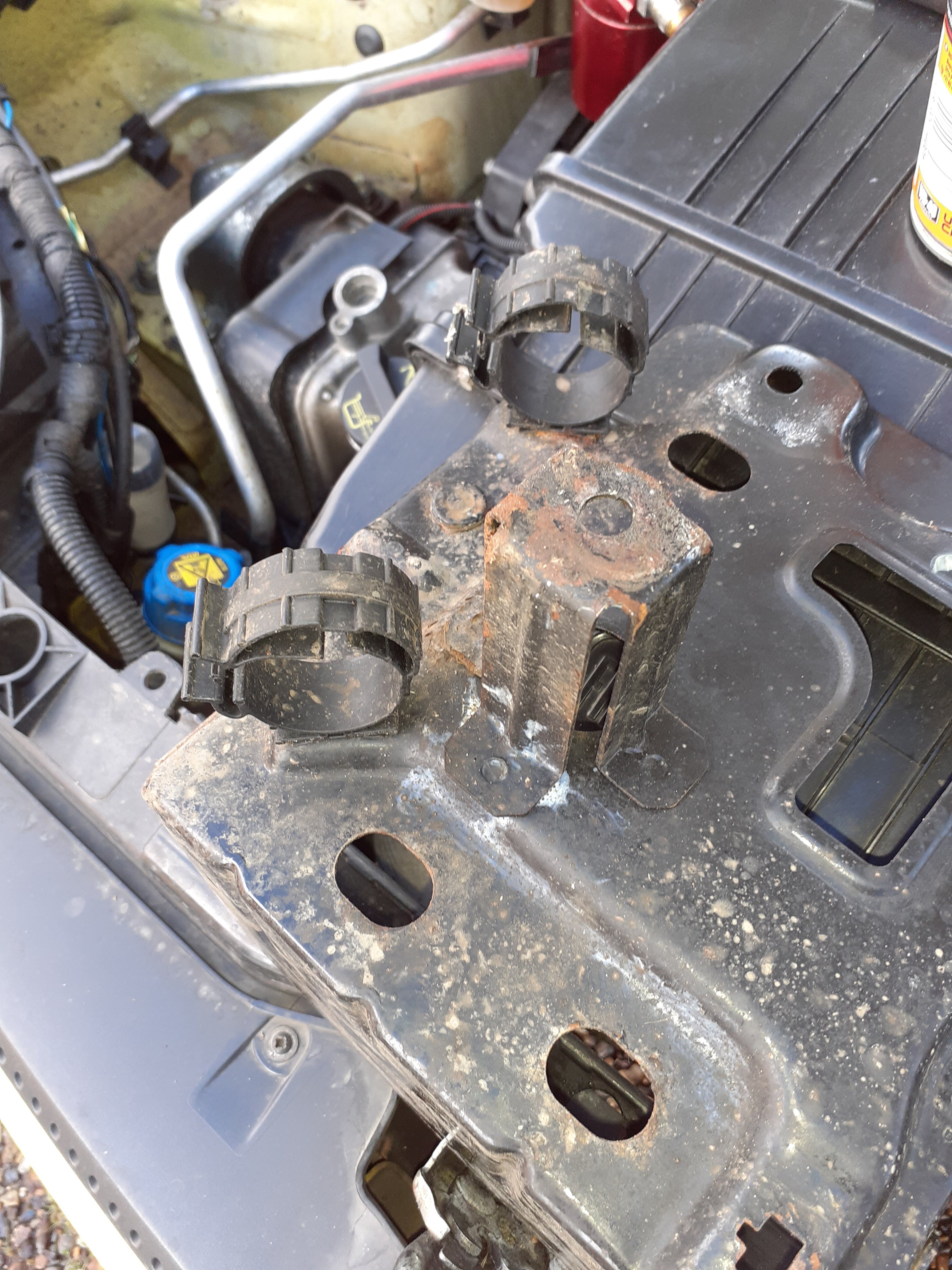

This pic shows the cable clips that hold the main wiring harness under the battery tray, so yo can see how the open. Just prise open by inserting and twisting a flat blade screw driver. Its awkward but not too hard.

The lower end of the hose is also a push fit so replacement is just a case of pushing the end onto the little spiggot See pic. Its worth saying at this time that both of these spiggots are fragile and if you break them it will be a significant problem. I have previously broken the small one under the air box. If you do have a disaster, some Speedy Fix glue for black plastic may get you out of trouble.

When replacing the hose its important to note two things.

1. the lower spiggot is 8mm so a 4 mm bore hose will not fit. AT the top its a 4mm spiggot! I used an 8mm drill to ream out the end 15mm of my 4mm bore hose. Take care not to end up with the hose or your hand twisted when drilling out the end. I used silicon spray in the end of the hose to help allow the drill work freely until the end of the hose https://www.ebay.co.uk/itm/321600159659was enlarged to 8mm internal bore.

2, The pipe only needs to be pushed onto the manifold spiggot about 10mm. There is a ridge on the spiggot that stops the hose being pushed on further even though it appears it might need to do so.

Reassembly is just a reverse job but make sure the pipe is not kinked or hanging low. Route any extra length so there are no places where oil or water can gather and block it.While we are here here are a few other useful bits.

The main earth strap that causes so much grief. This is in good condition. I have removed it cleaned it and massaged it with copper grease.

In red is the joining block for the pipes from the clutch master cylinder, and to the slave cylinder. It looks totally seized so I left the clutch slave pipe in place when replacing the cylinder Below is the slave cylinder pipe retaining clip that just flips out of the way with a small scredriver seen in the pic. Once this little clip is pulled up, the pipe and its steel end pull out of the slave cylinder. I changed the O rings on the pipe before reassembly.

You can clearly see the bleed outlet and the bleed screw (allen key type too).

You can clearly see the bleed outlet and the bleed screw (allen key type too).

I find the standard hose a bit short, to the extent it pulls off when you touch the air box, and is not long enough to allow you turn the air box over without removing it, or to see to attach it again. As the hose on my car has cracked and split I decided to change it and extend it a little to alleviate the above issues.

Tools needed and equipment

- 10mm socket and extension

- 13mm socket

- click R click plers or tools to remove clips pliers and screwdriver with flat blade or mini hacksaw.

- Screw drivers

- Padded glove to avoid scraping kncklwes when pulling the old hose off the manifold

- Sharp knife to cut hose Jubilee clips if required to replace any damaged hose clips.

- 18" length of 4mm hose https://www.ebay.co.uk/itm/321600159659

- 8mm drill and elctric drill

- Silicon spray

1. Remove the air intake spout

2. Remove the two 10mm bolts that secure the air box and carefully lift the air box off the throttle body and back mount.

Lift straight up to avoid straining or breaking the back mounting.

3. Remove the clip attaching the crank case breather hose to the spiggot on the cam cover and pull the hose away

4. Remove air box and put aside.

5. Pull the big breather hose off the air box. (Its the little pipe)

4 Pull the thin hose from the copper spiggot under the air box so its now free and ready for removal at its lower end where it fixes to the inlet manifold.

At this point I decided to remove the battery as the hose lower fitting was very tight and hard to pull off, even though there are no hose clips. If you are able to reach down the back of the engine without extra space thats good. I recommend you wear a glove to protect your hand from knocks and scratches though.

This pic shows the cable clips that hold the main wiring harness under the battery tray, so yo can see how the open. Just prise open by inserting and twisting a flat blade screw driver. Its awkward but not too hard.

The lower end of the hose is also a push fit so replacement is just a case of pushing the end onto the little spiggot See pic. Its worth saying at this time that both of these spiggots are fragile and if you break them it will be a significant problem. I have previously broken the small one under the air box. If you do have a disaster, some Speedy Fix glue for black plastic may get you out of trouble.

When replacing the hose its important to note two things.

1. the lower spiggot is 8mm so a 4 mm bore hose will not fit. AT the top its a 4mm spiggot! I used an 8mm drill to ream out the end 15mm of my 4mm bore hose. Take care not to end up with the hose or your hand twisted when drilling out the end. I used silicon spray in the end of the hose to help allow the drill work freely until the end of the hose https://www.ebay.co.uk/itm/321600159659was enlarged to 8mm internal bore.

2, The pipe only needs to be pushed onto the manifold spiggot about 10mm. There is a ridge on the spiggot that stops the hose being pushed on further even though it appears it might need to do so.

Reassembly is just a reverse job but make sure the pipe is not kinked or hanging low. Route any extra length so there are no places where oil or water can gather and block it.While we are here here are a few other useful bits.

The main earth strap that causes so much grief. This is in good condition. I have removed it cleaned it and massaged it with copper grease.

In red is the joining block for the pipes from the clutch master cylinder, and to the slave cylinder. It looks totally seized so I left the clutch slave pipe in place when replacing the cylinder Below is the slave cylinder pipe retaining clip that just flips out of the way with a small scredriver seen in the pic. Once this little clip is pulled up, the pipe and its steel end pull out of the slave cylinder. I changed the O rings on the pipe before reassembly.