You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Brake Fluid Tester temptation

- Thread starter Pugglt Auld Jock

- Start date

Currently reading:

Brake Fluid Tester temptation

Thanks. I might just try that sometime if I'm looking for something interesting to do.You could try simulating water content. For about 200 ml of brakefluid, 0,5% means 1 ml in volume. You could see instantly how accurate it is.

I was having one last thought on this subject earlier this morning. I prefer not to pump the brake pedal for bleeding - because of the possibility of causing damage to the master cylinder by operating it through part of the stroke it normally wouldn't be operated. My Gunson eezibleed is now very old and the seals are not sealing very well any more. besides, being an older version, many of the adaptor caps aren't relative to more modern vehicles. Then there's the fact that I've had a couple of "floods" lately due to the caps not sealing properly. I've messed about making seals from old inner tubes etc but it's far from ideal - so, time to "retire" it and I've been giving thought to what to replace it with. I've just had a wee "flashlight" moment which was brought on by something s130 said yesterday. "As for big dealersI suspect some/many??? put whatever they can find left over on the shelf in and tick the "brake fluid change box"

I've realized I've been guilty of this in the past in that I've left unused, new at the time, fluid in the eezibleed and simply topped it up with new when I came to use it next time. As the years have gone by and my car fixing activities have gone into decline this means there may well have been a small amount of fluid in the eezibleed which, although never used, could be almost a year old on occasion! Reflecting on this I now remember the much larger power bleeder we had at work was pretty much never emptied - unless you could see contamination in the reservoir - new fluid just being added as needed. I doubt if this was a problem though as the bleeder would likely be used several times a day and certainly many times in a week, so the fluid was being topped up all the time.

So, although I don't like the way they drag air in past the bleed nipple threads, I think I'm going to go for a vacuum bleeder this time. Simpler to use and the fluid you end up with in the container at the end of the operation will all be old fluid so I won't be tempted to keep it! Was it you PB? or you Charlie? who recommended wrapping the bleed nipple threads with PTFE plumber's tape to stop the air draw problem? I like that idea and it occurs to me that it may also stop/slow down corrosion of the threads long term thus making things easier next time you need to bleed.

On the subject of big dealers/any dealers doing brake fluid changes. From the workshop viewpoint this task can be a bit of a poison chalice, especially if the car is older, as it's very easy to break bleed nipples on the older vehicles due to the nipples being solidly corroded into their threads. We had a disclaimer on our job sheets (which the customer signed at check in) and if a fluid change was to be performed the reception would call the customer's attention to it and mention that if nipples do break then further work and maybe parts would be needed. Customers nearly always declined a fluid change even when the dangers of not doing it were mentioned. I would be very interested to know how often a "fluid change" consists of sucking out the reservoir contents and refilling with new fluid without doing any system bleeding? Of course this practice makes using a fluid tester on the reservoir a complete waste of time and could give a false sense of security.

As an "add on" to my above post, and especially regarding seized bleed nipples, people might like to take a look at the Vibroshock tool. I made a post recently about mine and how I'm using it here - 4th post down, just in case you missed it: https://www.fiatforum.com/threads/check-glow-plugs.496633/#post-4654767 It's continuing to be very useful and recently slackened the front disc retaining screws on my boy's Punto almost effortlessly.

The Panda Nut

Nutty about Pandas Infected by Panda virus and OPD

I love it when someone else misreads a woman as badly as do I!!Had bigger and dirtier things than that in the oven, for instance dynamo/alternator end plates, small engine crankcase halves and even a hub assembly to expand it when fitting wheel bearings. Also put things like bearings and flanges in the freezer. We started going out together in our teens and she's grown up with me building motor bike engines on the kitchen table when we lived in the London flat and using the kitchen sink as a parts cleaner. As long as I cleaned up after she didn't seem to mind too much. Mind you, although I still use the oven and freezer, it's been years since I did anything like cleaning stuff in the sink as our second house had a garage as has all subsequent houses.

Long suffering would cover it I think - on her part that is.I love it when someone else misreads a woman as badly as do I!!

The Panda Nut

Nutty about Pandas Infected by Panda virus and OPD

Makes the whole job a waste of time if you dont change the fluid at the hot and dirty end! I would go balistic if I found anyone doing that on my car its not changing the fluid at all. Touch wood I have not had a bleed nipple break off for well lver 40 years. I reckon if it did new cylinders / calipers are probably due anyway. Trouble starts if you buy second hand and this job is well over due,Thanks. I might just try that sometime if I'm looking for something interesting to do.

I was having one last thought on this subject earlier this morning. I prefer not to pump the brake pedal for bleeding - because of the possibility of causing damage to the master cylinder by operating it through part of the stroke it normally wouldn't be operated. My Gunson eezibleed is now very old and the seals are not sealing very well any more. besides, being an older version, many of the adaptor caps aren't relative to more modern vehicles. Then there's the fact that I've had a couple of "floods" lately due to the caps not sealing properly. I've messed about making seals from old inner tubes etc but it's far from ideal - so, time to "retire" it and I've been giving thought to what to replace it with. I've just had a wee "flashlight" moment which was brought on by something s130 said yesterday. "As for big dealersI suspect some/many??? put whatever they can find left over on the shelf in and tick the "brake fluid change box"

I've realized I've been guilty of this in the past in that I've left unused, new at the time, fluid in the eezibleed and simply topped it up with new when I came to use it next time. As the years have gone by and my car fixing activities have gone into decline this means there may well have been a small amount of fluid in the eezibleed which, although never used, could be almost a year old on occasion! Reflecting on this I now remember the much larger power bleeder we had at work was pretty much never emptied - unless you could see contamination in the reservoir - new fluid just being added as needed. I doubt if this was a problem though as the bleeder would likely be used several times a day and certainly many times in a week, so the fluid was being topped up all the time.

So, although I don't like the way they drag air in past the bleed nipple threads, I think I'm going to go for a vacuum bleeder this time. Simpler to use and the fluid you end up with in the container at the end of the operation will all be old fluid so I won't be tempted to keep it! Was it you PB? or you Charlie? who recommended wrapping the bleed nipple threads with PTFE plumber's tape to stop the air draw problem? I like that idea and it occurs to me that it may also stop/slow down corrosion of the threads long term thus making things easier next time you need to bleed.

On the subject of big dealers/any dealers doing brake fluid changes. From the workshop viewpoint this task can be a bit of a poison chalice, especially if the car is older, as it's very easy to break bleed nipples on the older vehicles due to the nipples being solidly corroded into their threads. We had a disclaimer on our job sheets (which the customer signed at check in) and if a fluid change was to be performed the reception would call the customer's attention to it and mention that if nipples do break then further work and maybe parts would be needed. Customers nearly always declined a fluid change even when the dangers of not doing it were mentioned. I would be very interested to know how often a "fluid change" consists of sucking out the reservoir contents and refilling with new fluid without doing any system bleeding? Of course this practice makes using a fluid tester on the reservoir a complete waste of time and could give a false sense of security.

The Panda Nut

Nutty about Pandas Infected by Panda virus and OPD

Shes a gem. I would be so very very dead if I brought anything into the house without a pre negotiated and formal written agreement and large damage deposit having been paid. In that case I would just be severely punished for many many years.Long suffering would cover it I think - on her part that is.

The Panda Nut

Nutty about Pandas Infected by Panda virus and OPD

Ha shes denied this and said its ok if I dont use one of her oven trays... But you must remember fine means no, no means no yes or may be and yes may mean no. Among the many mine fields that must be traversed with er indoors... or indeed outdoors!

I know my place.

I know my place.

Yes. I think it's safest to assume that either yes or no means maybe but with attached conditions. Best to ascertain the conditions before proceeding.Ha shes denied this and said its ok if I dont use one of her oven trays... But you must remember fine means no, no means no yes or may be and yes may mean no. Among the many mine fields that must be traversed with er indoors... or indeed outdoors!

I know my place.

Knowing one's place is fundamental to harmonious co-existence. As is being prepared to eat humble pie.

I once tried using using my Gunson Eezibleed on one of my older Fiats and the fluid was everywhere except in the reservoir. Took ages to clean up the mess. I don't think I ever used it again. I just use the bottle as a catch bottle when bleeding by pumping.

However, I'm now seriously think of the Sealey VS1205

https://www.sealey.co.uk/product/5637204882/brake-clutch-bleeder

Being able to gently manually pump pressure the system is hopefully going to be more accurate (by feel and bleed results) than just connecting to a tyre at some nominal low PSI.

As you pump up if there are any leaks then you can abort immediately and at a low pressure.

Instructions even say:

"No fluid - Pump the handle to pressurise, make sure there are no leaks, fig.2. 4.4. Release the pressure and fill the bottle with new brake fluid, fig.3"

Also with Sealey they provide spare parts for this as well.

However, I'm now seriously think of the Sealey VS1205

https://www.sealey.co.uk/product/5637204882/brake-clutch-bleeder

Being able to gently manually pump pressure the system is hopefully going to be more accurate (by feel and bleed results) than just connecting to a tyre at some nominal low PSI.

As you pump up if there are any leaks then you can abort immediately and at a low pressure.

Instructions even say:

"No fluid - Pump the handle to pressurise, make sure there are no leaks, fig.2. 4.4. Release the pressure and fill the bottle with new brake fluid, fig.3"

Also with Sealey they provide spare parts for this as well.

Haven't seen that one but I'm aware of this one: https://www.sealey.co.uk/product/5637206325/25l-brake-clutch-bleeding-system Which can be found on ebay for under £60. There are cheaper versions around but what you'd do for spares I don't know. I do like the idea of pressurizing the system rather than sucking at the bleed nipple but my "disasters" with the Gunson tool have rather put me off! I'm thinking about a vacuum system to replace the Gunson but I'm still swithering. If rather like the idea of a hand held vacuum pump - if I do go with vacuum - something like this perhaps: https://www.ebay.co.uk/itm/353742509277?hash=item525cb254dd:g:ZXIAAOSwpJJhdnxE&amdata=enc:AQAHAAAA4JoT1ymJYR7uSebdoxi40NuwK3TTiPwEMiYMUYvEhIYkSeMAemmTP8pQGGipjxTl+chiTmrfLp4+h2AclVDUbisTB9ehG53hxRk2yma/Zxyoi3v7xrVHXvObHyCa5/IWka56qJRGnXVSskd7ovVRxS7HVBLvqTXR0n/WlVSVeb7CiqxEK6UTnKVhh8NWCgFALiO4JW2hPccn1KLyBUrCLDfQkdekX69lYVbws4xi0hS+v602KgPx03wvC2x7Pnz54HEo0PScIcgyjT7Fj8JoMlZ/JEaZMQ7cUGkuI6T8Nz8e|tkp:BFBM-NOKnIph as it can also be used to apply suction to things like MAP sensors, old type turbo actuators, and other stuff when diagnosing problems. Or maybe I should just get both?I once tried using using my Gunson Eezibleed on one of my older Fiats and the fluid was everywhere except in the reservoir. Took ages to clean up the mess. I don't think I ever used it again. I just use the bottle as a catch bottle when bleeding by pumping.

However, I'm now seriously think of the Sealey VS1205

https://www.sealey.co.uk/product/5637204882/brake-clutch-bleeder

Being able to gently manually pump pressure the system is hopefully going to be more accurate (by feel and bleed results) than just connecting to a tyre at some nominal low PSI.

As you pump up if there are any leaks then you can abort immediately and at a low pressure.

Instructions even say:

"No fluid - Pump the handle to pressurise, make sure there are no leaks, fig.2. 4.4. Release the pressure and fill the bottle with new brake fluid, fig.3"

Also with Sealey they provide spare parts for this as well.

This post contains eBay links which may earn a commission at no additional cost to you.

I'm not sure that would work well as they'd just separate. Oil and water dont mix (unless your headgasket goes!!) but not sure much more more is absorbed if sitting liquid to liquid.You could try simulating water content. For about 200 ml of brakefluid, 0,5% means 1 ml in volume. You could see instantly how accurate it is.

I guess both systems (suction vs pressure vs pedal pump) have their advantages / disadvantages

Pressure: Less easy to run out of brake fluid if you suck the old fluid out of the reservoir and fill with new and of course you have the filler bottle contents as well. Easier to open nibble and not have to suction pump at same time

Suction: No pressure fluid leaks at reservoir. Limited / frequent reservoir checks required. Air bubbles in suction pipe unless you can effectively seal the nipple threads.

Pedal Pump: No tools required. Two persons required. Synchronisation of Up/Down & nipple Open/Close often required. No continuous fluid flow so on difficult to bleed systems can be rather tedious and frustrating getting all the air out.

Pressure: Less easy to run out of brake fluid if you suck the old fluid out of the reservoir and fill with new and of course you have the filler bottle contents as well. Easier to open nibble and not have to suction pump at same time

Suction: No pressure fluid leaks at reservoir. Limited / frequent reservoir checks required. Air bubbles in suction pipe unless you can effectively seal the nipple threads.

Pedal Pump: No tools required. Two persons required. Synchronisation of Up/Down & nipple Open/Close often required. No continuous fluid flow so on difficult to bleed systems can be rather tedious and frustrating getting all the air out.

Meant to add 'More likely to have fluid leaks'Pressure: Less easy to run out of brake fluid if you suck the old fluid out of the reservoir and fill with new and of course you have the filler bottle contents as well. Easier to open nibble and not have to suction pump at same time

I wish the post edit timeout were longer! Ben ... where are you with this?

The 'cheaper' of the two Sealey pressure systems seems to be like my memoriy of the Gunson one, where it will fill the master cylinder reservoir to the brim. That gets very messy once you're done. The expensive one seems to have a stem to the cap, which will hopefully maintain some air space in the reservoir, and avoid the mess.

It is disappointing that Gunson do not seem to have updated theirs with different caps, sticking with the ones for old British cars.

It is disappointing that Gunson do not seem to have updated theirs with different caps, sticking with the ones for old British cars.

I've been looking at vacuum bleeders and I've caught myself thinking "you could make something like that" So I've just been round a couple of our local tyre fitting shops and collected some used tyre valve stems and cores, They gave me handfulls of them so if anyone needs vale cores be aware this could be a good free source? I also have some coils of different sized clear tubing (like screen washer tube) and a big thick glass pickle jar. To create the vacuum I'm going to try reversing the washer in a bycicle pump so it sucks instead of blowing. My thinking is that bike tyres are often blown up to around 30 psi or more, so it should be able to suck a good vacuum being as how atmospheric pressure is only around 15psi - or is my thinking flawed?

The second workshop I stopped at was the small independent tyre supplier/repair shop just up the road. As I was leaving he called me back and asked me if I'd like to work for him. My guess would be on tyres and deliveries as he seems to supply others in the trade with tyres. He's actually asked me before, a couple of years ago, but he seems to have forgotten that. I declined at this time but told him I wasn't completely burying the idea for the future to which he invited me to come talk to him at any time. Hasn't half swelled my ego! However age, arthritis, and family commitments probably make this impractical much as the idea attracts me. I started out, late on in the '60's, with tyres. It would have been nice for my last job to have been in the same trade. Maybe sounds strange, but I like the smell of new tyres. It takes me right back there every time!

The second workshop I stopped at was the small independent tyre supplier/repair shop just up the road. As I was leaving he called me back and asked me if I'd like to work for him. My guess would be on tyres and deliveries as he seems to supply others in the trade with tyres. He's actually asked me before, a couple of years ago, but he seems to have forgotten that. I declined at this time but told him I wasn't completely burying the idea for the future to which he invited me to come talk to him at any time. Hasn't half swelled my ego! However age, arthritis, and family commitments probably make this impractical much as the idea attracts me. I started out, late on in the '60's, with tyres. It would have been nice for my last job to have been in the same trade. Maybe sounds strange, but I like the smell of new tyres. It takes me right back there every time!

Ooops, Mrs j says I can't have the pickle jar!

She'll probably guess if you eat all the pickles.Ooops, Mrs j says I can't have the pickle jar!

The jar's empty already but I've been told it's part of her jam making apparatus so strictly off limits!She'll probably guess if you eat all the pickles.

Anyway I've already found a reasonably suitable replacement:

The only concern is that I think the lid seal:

is almost certainly not compatible with brake fluid so after a while it's likely to disintegrate. Hopefully it should last long enough for me to try it all out to test the concept and if it proves a "goer" then I'll either make a better seal - from an old inner tube maybe? - or find a better container all together.

Here's my wee treasure trove of valve stems, cores and other stuff:

About half of which I collected yesterday.

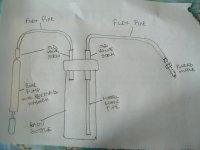

Here's a, rather poor, drawing of what I'm trying to make:

The valve stems are acting as "terminals" for fixing the flex tubing to and, obviously, I'm going to need to maintain vacuum in the container on the return stroke of the pump. I'm trying to make my mind up whether I'd be better to have a core in the stem directly attached to the outlet of the pump or to the inlet to the bottle. As long as I can achieve a good seal on the tubing I think having it directly on the outlet from the pump would be most efficient. Actually, that's a bit of a silly thing to say isn't it? because if the whole system, let alone the pipes, doesn't seal well then the whole enterprise is doomed!

If it all works well I'm thinking I could remove the pipe from the inlet of the bottle and fit a "T" piece so I could T in with my vacuum gauge then add another length of flex pipe to the other leg of the "T" and I've got myself a calibratable vacuum source which could be used for testing stuff like turbo actuator diaphragms (on older type turbos without motor driven wastegates) MAP sensors, and other stuff.

Hey, this is quite exciting me!

I was pondering all of this then came up with another probably totally inaccurate test

So given I've declared this idea is pants, let us proceed

On my central heating system, I check the quality of the anti-corrosive and inhibitor strength/quality by putting a simple tin-tac/nail (not protected in any way) into a sample of central heating fluid and a side/comparison test of tap water. it does not take long for the obvious differences to become evident (clean shiny nail vs rusty nail).

I have no chemical knowledge idea about how these inhibitors work but clearly, we have a 95%+ water base solution with some 5% additive that stops corrosion and sludge buildup.

With brake fluid we have an opposite. 95% base fluid with 5% water content.

Now being a tropical fish keeper the "test strips" are a common and diagnostic for many different types of contaminants.

So why has nobody come up with a simple "dip & test" test strip that can indicated the percentage of water in brake fluid.

Seems like (for me) a blaring hole in the Automotive/similar industry!

Now that I've given the idea I claim, in public, announced "Prior Art", to protect my IP interests.

So given I've declared this idea is pants, let us proceed

On my central heating system, I check the quality of the anti-corrosive and inhibitor strength/quality by putting a simple tin-tac/nail (not protected in any way) into a sample of central heating fluid and a side/comparison test of tap water. it does not take long for the obvious differences to become evident (clean shiny nail vs rusty nail).

I have no chemical knowledge idea about how these inhibitors work but clearly, we have a 95%+ water base solution with some 5% additive that stops corrosion and sludge buildup.

With brake fluid we have an opposite. 95% base fluid with 5% water content.

Now being a tropical fish keeper the "test strips" are a common and diagnostic for many different types of contaminants.

So why has nobody come up with a simple "dip & test" test strip that can indicated the percentage of water in brake fluid.

Seems like (for me) a blaring hole in the Automotive/similar industry!

Now that I've given the idea I claim, in public, announced "Prior Art", to protect my IP interests.

Similar threads

- Replies

- 1

- Views

- 536