The idea is to get the tension the same on the whole timing belt, not only on the 'tight' side that's being pulled by the crankshaft. You will have enough play on the tensioner without over stretching the belt itself.

Same idea, different manufacturer: VAG TDI timing belt

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical 2009 Panda 1.1 timing belt change.

- Thread starter Woodbeck

- Start date

Currently reading:

Technical 2009 Panda 1.1 timing belt change.

fiat have use this method on some of there enginesThe idea is to get the tension the same on the whole timing belt, not only on the 'tight' side that's being pulled by the crankshaft. You will have enough play on the tensioner without over stretching the belt itself.

Same idea, different manufacturer: VAG TDI timing belt

but according to elearn its not the preferred method for the 500 or panda where the camshaft pully timing is set with Fiat tool 2.000.004.200 not the belt and once set correctly and accurately using the tool, I dont understand why you would ever need to alter it

3234dmtr

Member

- Joined

- Oct 4, 2015

- Messages

- 11

- Points

- 77

The eLearn is a snapshot and not up to date, since the 169A4.000 engine is not present in the Panda section, only in the 500 section. I'm specifically writing about this particular Euro 5 engine, which doesn´t have the fixed camshaft pulley. On a fixed camshaft pulley however, I wouldn´t bother about it, since it's contructed that way. Align the marking positions and rock 'n' roll. Have done a lot this way.fiat have use this method on some of there engines

but according to elearn its not the preferred method for the 500 or panda where the camshaft pully timing is set with Fiat tool 2.000.004.200 not the belt and once set correctly and accurately using the tool, I dont understand why you would ever need to alter it

Vendor info on the 169A4.000:

Conti

SKF

SKF instructions uses locking tool 19 to put the sprocket back exactly where it was originallyThe eLearn is a snapshot and not up to date, since the 169A4.000 engine is not present in the Panda section, only in the 500 section. I'm specifically writing about this particular Euro 5 engine, which doesn´t have the fixed camshaft pulley. On a fixed camshaft pulley however, I wouldn´t bother about it, since it's contructed that way. Align the marking positions and rock 'n' roll. Have done a lot this way.

Vendor info on the 169A4.000:

Conti

SKF

Trust me undoing the cam pully is a complete waste of time.

you just can not quite fit the belt with both the cam and Crank locked

I have just fitted a new belt to an 2011 eco

3234dmtr

Member

- Joined

- Oct 4, 2015

- Messages

- 11

- Points

- 77

You're right that you can't fit the belt with the locking tools on AND the camshaft pulley not loosened. Hence, that's where the procedure states to loosen this, just like VAG. Only thing is that VAG explains why it's done that way.SKF instructions uses locking tool 19 to put the sprocket back exactly where it was originally

Trust me undoing the cam pully is a complete waste of time.

you just can not quite fit the belt with both the cam and Crank locked

I have just fitted a new belt to an 2011 eco

But, each to their own, as long as the job gets done without issues, it will always be the correct way.

Did a timing belt job on a 2011 Dynamic 2 weeks ago, the camshaft pulley thingy literally took less then 5 minutes from my life. To fiddle the heatshield back in place on this vehicle equipped with airconditioning took much more effort.

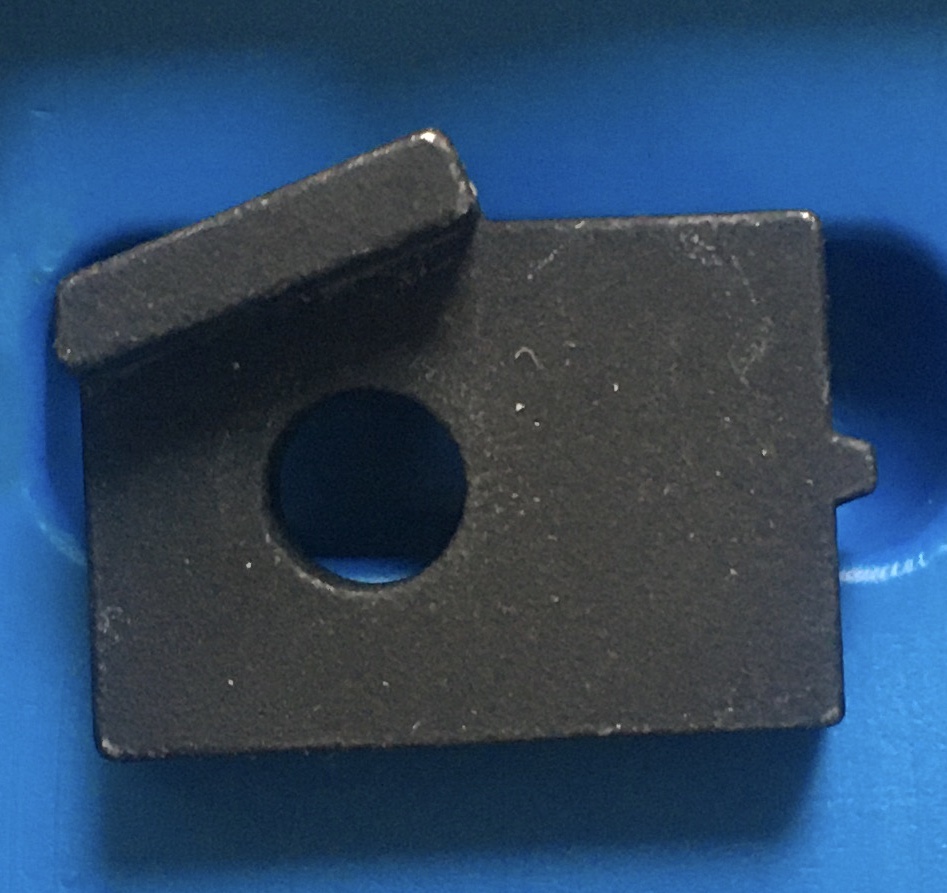

Do you know the make of your cam lock? I have a Sealey one but it will only fit 180 degrees out from your picture - i.e. with the square slot facing down. This is because the base plate of the tool is too thick to engage in the "correct" orientation. In theory it shouldn't matter which of the two positions you set things up (if it really is exactly 180 degrees out - it seems to be "by eye"), but I have a persistent error showing after a cambelt change with my tool and I'd like to rule it out.....thanks!yes it will fit and bolt two way 180 degrees apart

the correct one is with the square cut out at the top

I assumed its similar to mine ?

View attachment 407237

Nick

Cheap China special

Bottom picture are the only bits you need, the middle one only if someone has already loosened the camshaft pulley

Bottom picture are the only bits you need, the middle one only if someone has already loosened the camshaft pulley

Too far advanced by any chance ?but I have a persistent error showing after a cambelt change with my tool

Yes I'm wondering if the timing is now just too different from what it had become with the old belt (the crank tool was probably about 5mm out at the narrow end when I checked the old belt). So I wonder if i try and replicate that now, the new setup would be accepted (or at least learnable). Seems bizarre to move from correct timing back to the old incorrect setting but if it works it works.

Unfortunately I can't remember in which direction the old belt was out. Do they always stretch in a particular direction? Driven pulley (cam) might tend to lag driving pulley (crank) as it loosens up perhaps? So with cam locked, crank would be a few mm in advance, I.e. clockwise. Maybe - that's a guess.

I suppose I can do it once in advance and once in retard.... this is where the loosenable cam pulley might be a help...

What a palaver - I note this only seems to be a Marelli thing. The "Italian Lucas" strikes again...

Nick

Unfortunately I can't remember in which direction the old belt was out. Do they always stretch in a particular direction? Driven pulley (cam) might tend to lag driving pulley (crank) as it loosens up perhaps? So with cam locked, crank would be a few mm in advance, I.e. clockwise. Maybe - that's a guess.

I suppose I can do it once in advance and once in retard.... this is where the loosenable cam pulley might be a help...

What a palaver - I note this only seems to be a Marelli thing. The "Italian Lucas" strikes again...

Nick

Right I did a few experiments while I was doing mine

There are two different teeth the belt can be on and the locking tool will fit. In either position the locking tools only just fit

You can tell the difference while turning the crank by hand. The compression is much higher. Unfortunately I can’t describe the difference you have to have experienced the correct timing for yourself

Next I will post how I did mine

There are two different teeth the belt can be on and the locking tool will fit. In either position the locking tools only just fit

You can tell the difference while turning the crank by hand. The compression is much higher. Unfortunately I can’t describe the difference you have to have experienced the correct timing for yourself

Next I will post how I did mine

First of I checked the camshaft pulley is in the correct alignment to the camshaft.

With the camshaft locked with the tool at the back, slide the tool in middle of my lower picture and make sure the tooth on it is aligned with the tooth on the pulley

On my engine with my belt kit there is absolutely no way to fit the belt correctly with both the cam and crank locked. Yes it will go on just but will always be one tooth advanced. Yes it fits and looks right but the tight side isn’t supper tight as it needs to be

What I did was, put the belt on the crank, and wedged it on with a rag under it so it can’t slip. Then removed the camshaft locking tool lift belt up to the pulley, with a large spanner on the camshaft moved it anti clockwise half a tooth so the belt falls in easily and then followed the rest of the elearn fiat 500 timing belt guide

After setting the tensioner to max do two complete revolutions of the crank and make sure the locking tools fit or very close. It’s very important not to turn the crank backwards if you go past do another revolution in the clockwise direction

With the camshaft locked with the tool at the back, slide the tool in middle of my lower picture and make sure the tooth on it is aligned with the tooth on the pulley

On my engine with my belt kit there is absolutely no way to fit the belt correctly with both the cam and crank locked. Yes it will go on just but will always be one tooth advanced. Yes it fits and looks right but the tight side isn’t supper tight as it needs to be

What I did was, put the belt on the crank, and wedged it on with a rag under it so it can’t slip. Then removed the camshaft locking tool lift belt up to the pulley, with a large spanner on the camshaft moved it anti clockwise half a tooth so the belt falls in easily and then followed the rest of the elearn fiat 500 timing belt guide

After setting the tensioner to max do two complete revolutions of the crank and make sure the locking tools fit or very close. It’s very important not to turn the crank backwards if you go past do another revolution in the clockwise direction

Ok thanks - but sounds like you didn't loosen the cam pulley? Doing that means you can always easily fix the timing precisely. But ironically the Marelli engine management software seems to work against that...you'd think it would always accept true timing though....

Nick

Nick

I didn’t loosen the pulley

If you do it needs to be reset using this tool

Both ways work

If you do it needs to be reset using this tool

Both ways work

I know it doesn’t seem possible to be a tooth out when both the cam and crank are locked but it absolutely can. When fitting the belt it feels like it’s half a tooth out depend on which tooth you fall onto it will either be correct or advanced.

In either position the lock tools will fit although better when correct.

In either position the lock tools will fit although better when correct.

So thinking about what you did, you did indeed retard the cam a little with respect to the crank, which was also my hypothesis. Presume it all worked for you without errors (or need for relearn?).

Nick

Nick

Correct it self learnsSo thinking about what you did, you did indeed retard the cam a little with respect to the crank, which was also my hypothesis. Presume it all worked for you without errors (or need for relearn?).

Nick

If the expected signal from the camshaft is too far from expected position it will throw an error. There is no way to correct this.

I don’t know what the tolerance is but one tooth is too much

I have seen them at just under 1/2 a tooth running fine

- Joined

- Sep 14, 2009

- Messages

- 19,899

- Points

- 3,414

This is why I marked the cam position before removing the old belt and put it back to the same settings with the new belt. Toothed belts do not stretch (unlike a cam chains) so the timing alignment cannot significantly retard even with severely worn teeth. In my case, there was no measurable wear on the old belt teeth.I know it doesn’t seem possible to be a tooth out when both the cam and crank are locked but it absolutely can. When fitting the belt it feels like it’s half a tooth out depend on which tooth you fall onto it will either be correct or advanced.

In either position the lock tools will fit although better when correct.

correct, there was no measurable wear on the old belt teeth.

- Joined

- Sep 14, 2009

- Messages

- 19,899

- Points

- 3,414

The old 2007 Panda 1.2 timing belt was the original yet it looked good as new. I let it run as these are supposed to be "safe" engines.correct

About 12 years ago, I had a Punto Mk2 HGT that I stupidly used knowing the timing belt was old. The results were inevitable. The old belt teeth stripped off, yet it looked fine from the smooth side. Even the tensioner bearing felt good. I repaired the head and the car gave good service. Thankfully the crank bearings survived.

Similar threads

- Replies

- 23

- Views

- 455