That’s probably because the original radio and body computer do a cross check on each other - part of the security and why if you swap to a different Fiat radio it won’t work.Yeah since the stereo was upgraded to the Pioneer unit

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Panda 2012+ What's needed to run MultiECUScan?

- Thread starter SB1500

- Start date

Currently reading:

Panda 2012+ What's needed to run MultiECUScan?

I know the car in question is petrol, but note that with a diesel version you ‘have’ to reset the ‘change oil’ as well as the ‘service due’Petrol.. Or Turbo..?

Basically I've not got round to "Resetting the parameters".

On mine I've had to compromise on oil used.. So wanted to see how JUST AN OIL Change. made the tiny motor run

Punto noisier.. But running well (castrol)

Panda.. Sounded unchanged.. Seemed 'flat'. For @100 miles.. Then performance ok (miller's)

Yes.. I would Love to do the resets and get it 'optimised'

(but a regular on here had a major issue doing the reset and wondered if it had killed the Uniair on an elderly TA)

So I am Confident in saying it's NOT crucial.. Even the service message times out..

Just a thought. simple ramps like these aren't something that wears out - like say a hydraulic jack. If damaged it's pretty easy to see visually. Therefore I bet there will be used bargains to be had on the likes of eBay/Gumtree etc?

If you're looking at tools in Halfords then their Advance/Professional range is pretty good and, I think, guaranteed for life. I've got a number of their offerings and find them very satisfactory. I'd steer clear of their more DIY offerings if you are going to be putting them to any serious work though.

Another good value and quality outlet is Machine Mart - same caveat applies, don't just go for the cheapest option. Always worth giving them your email address as they do VAT free days from time to time and they'll notify you by email before the event. Have to say they've been doing less of this since the covid pandemic though. I've had some real bargains like this: https://www.machinemart.co.uk/p/clarke-ctj2qlp-2-tonne-quick-lift-low-profile/ which, vat free, is a reasonable saving. Most of all I like buying this sort of thing from them because their spares backup is very good.

Good selection of ramps here, thanks.

Car Ramps - Machine Mart

No one’s mentioned it - there’s a version of MES for the iPhone too… but will only work with wireless OBD units, and I believe quite specific ones too. I downloaded the free trial version but it didn’t work with my cheap OBD unit. Also, I think you have to pay annually? I haven’t gone further, as having found The Fiat Workshop in nearby Royston I’ve let them do the oil changes.

Last edited:

Sorry, I didn't address that. raising the car is possible with the car's own jack but I don't like doing it because the offering that comes with the car is usually pretty unstable also some don't really lift the car high enough. Therefore a trolley jack is to be preferred and makes things much easier. Personally I find the cheapest trolley jacks, often around the £25 to £30 range, very frustrating to use because they don't have a very great range of lift so you can't get much extension on the axle stands and sometimes won't go under lower cars at all. Something like this: https://www.machinemart.co.uk/p/ctj2l-2-tonne-long-diy-trolley-jack/ is probably about as small as you would want to go to be useful. I have a couple of "breakdown" jacks (small enough to lift easily in and out of a vehicle) which have a 410mm max lift and I wouldn't want to go much smaller. When at home I have a couple of larger ones, like the low entry one I posted a link to above but you're only going to want to invest in something like that if you're going to be using it a lot. Here's a picture of the "breakdown" jacks with my old, more heavy duty, workshop jack in the background. You can see the workshop jack is much more stable due to it being wider and look at the length of the arm? This lets it lift quite a bit higher.Thanks, are axel stands easy to use? I presume that you need a trolley jack to use them or a pair of trolley jacks?

This is the modern version of my Breakdown jacks: https://www.sealey.co.uk/product/5637173115/3-tonne-long-reach-heavy-duty-trolley-jack It actually uses the same pumping element and ram as my older jacks do - I bet they're all made somewhere in China - but is slightly higher in the "down" position although it gains a little therefore when extended. Trouble is at this price you can buy a proper workshop 2/3 ton jobbie for only a little more which is probably the better option unless you're dragging it around in your boot.

How easy is it? Well, for someone with experience it's pretty easy. BUT, if you've no experience - and I guess that's you? or you wouldn't be asking? Then the problem becomes where to put the jacking pad and then where to position the axle stands. The good news is you can jack up one side and position the stand then go round to the other side and repeat until you have both front - or both rear - wheels off the ground. Where to position the jack pad and axle stands is always the problem and is a constant source of comment and disagreement on the forum. You can jack directly on the reinforced jacking points - on the sills of most modern vehicles, often indicated by a wee pressed in mark on the sill - and a jacking "puck" can be very useful to stop the jack slipping and minimize damage to the paintwork on the sills: https://www.ebay.co.uk/itm/13404030...nPhKeCxe+L1cjbM+54AhbnqqC+1n|tkp:BFBMzt_MhNti

Where to place the stands though? Well, definitely nowhere on a flat floor panel, it'll never take the weight. I tend to choose either a major box section under the floor or the engine subframe if working on the front end. One thing I strongly advise against is never to jack the rear end up in the middle of the rear axle. It might bend, especially when the vehicle gets older and corrosion weakens it, and it only takes a small bend in it to destroy the rear suspension geometry which will mean a new axle will be needed. I also like to put a block of wood on the stand where it contacts the car to minimize damage to underseal etc but also it tends to allow the metal of the car to "bite" into it which helps stop it slipping - Safety first always! Never, NEVER get under anything supported only on a jack. If it fails, and they can fail catastrophically quickly, it's a painful way to die.

Here's some pics of Becky's nether regions and my home made jack adapter which I made to spread the load when jacking on the sills. In many years of use I've never damaged a sill yet - oops, shouldn't have said that should I?

In the last image you can see how the axle stand has a wee wooden block between it and the box section, at the rear, I'm supporting the car on. Here's a couple where you can see where I've placed the stands when working on the front. Again, notice the wooden blocks:

Of course it's only sensible to check the sills for rust before you start jacking it up and take it easy for the first few strokes, listening as you go for crackling crunchy noises which might indicate the sills are weak and starting to collapse.

Hope that helps a little. Sorry for the pictures maybe not being that illustrative but I originally took them to illustrate the brake work i was doing on the car, not specifically to illustrate jacking practices.

This post contains eBay links which may earn a commission at no additional cost to you.

Thank you. That’s a really useful post and merits being moved to the guides section for all to see.Sorry, I didn't address that. raising the car is possible with the car's own jack but I don't like doing it because the offering that comes with the car is usually pretty unstable also some don't really lift the car high enough. Therefore a trolley jack is to be preferred and makes things much easier. Personally I find the cheapest trolley jacks, often around the £25 to £30 range, very frustrating to use because they don't have a very great range of lift so you can't get much extension on the axle stands and sometimes won't go under lower cars at all. Something like this: https://www.machinemart.co.uk/p/ctj2l-2-tonne-long-diy-trolley-jack/ is probably about as small as you would want to go to be useful. I have a couple of "breakdown" jacks (small enough to lift easily in and out of a vehicle) which have a 410mm max lift and I wouldn't want to go much smaller. When at home I have a couple of larger ones, like the low entry one I posted a link to above but you're only going to want to invest in something like that if you're going to be using it a lot. Here's a picture of the "breakdown" jacks with my old, more heavy duty, workshop jack in the background. You can see the workshop jack is much more stable due to it being wider and look at the length of the arm? This lets it lift quite a bit higher.

View attachment 430498

This is the modern version of my Breakdown jacks: https://www.sealey.co.uk/product/5637173115/3-tonne-long-reach-heavy-duty-trolley-jack It actually uses the same pumping element and ram as my older jacks do - I bet they're all made somewhere in China - but is slightly higher in the "down" position although it gains a little therefore when extended. Trouble is at this price you can buy a proper workshop 2/3 ton jobbie for only a little more which is probably the better option unless you're dragging it around in your boot.

How easy is it? Well, for someone with experience it's pretty easy. BUT, if you've no experience - and I guess that's you? or you wouldn't be asking? Then the problem becomes where to put the jacking pad and then where to position the axle stands. The good news is you can jack up one side and position the stand then go round to the other side and repeat until you have both front - or both rear - wheels off the ground. Where to position the jack pad and axle stands is always the problem and is a constant source of comment and disagreement on the forum. You can jack directly on the reinforced jacking points - on the sills of most modern vehicles, often indicated by a wee pressed in mark on the sill - and a jacking "puck" can be very useful to stop the jack slipping and minimize damage to the paintwork on the sills: https://www.ebay.co.uk/itm/134040307021?hash=item1f356cc54d:g:To0AAOSwFIdhRFvg&amdata=enc:AQAIAAAA4MAw+ao6aZ47UXYF28+vBZdLBc43aeiQIsVxt5lXLQmO2kTm7ErWZKUuBx9x9gApleDTuLp43y4vYicvBq2rizTxB4wde8REDNQlx8ihNcZfTbPOBm9M0rg0Q7z/6GNxNDQoBc/d3ds+X4WA+oY1lNhwXgxWtHfOUhqnfuucPx+dNU/tadp2caYOpXINZCoee7O98NEpTcUPdxW4Yf5fILYp2DOA5VoQNTwuK2rIEiF51EhoN8K4TOeDDWvENemfm4rECrK2uK741BYWnPhKeCxe+L1cjbM+54AhbnqqC+1n|tkp:BFBMzt_MhNti

Where to place the stands though? Well, definitely nowhere on a flat floor panel, it'll never take the weight. I tend to choose either a major box section under the floor or the engine subframe if working on the front end. One thing I strongly advise against is never to jack the rear end up in the middle of the rear axle. It might bend, especially when the vehicle gets older and corrosion weakens it, and it only takes a small bend in it to destroy the rear suspension geometry which will mean a new axle will be needed. I also like to put a block of wood on the stand where it contacts the car to minimize damage to underseal etc but also it tends to allow the metal of the car to "bite" into it which helps stop it slipping - Safety first always! Never, NEVER get under anything supported only on a jack. If it fails, and they can fail catastrophically quickly, it's a painful way to die.

Here's some pics of Becky's nether regions and my home made jack adapter which I made to spread the load when jacking on the sills. In many years of use I've never damaged a sill yet - oops, shouldn't have said that should I?

View attachment 430494View attachment 430493View attachment 430492

In the last image you can see how the axle stand has a wee wooden block between it and the box section, at the rear, I'm supporting the car on. Here's a couple where you can see where I've placed the stands when working on the front. Again, notice the wooden blocks:

View attachment 430496

View attachment 430497

Of course it's only sensible to check the sills for rust before you start jacking it up and take it easy for the first few strokes, listening as you go for crackling crunchy noises which might indicate the sills are weak and starting to collapse.

Hope that helps a little. Sorry for the pictures maybe not being that illustrative but I originally took them to illustrate the brake work i was doing on the car, not specifically to illustrate jacking practices.

This post contains eBay links which may earn a commission at no additional cost to you.

- Joined

- Mar 20, 2015

- Messages

- 150

- Points

- 99

I've just ordered itEverything here you need except for a win laptop.

MultiECUScan CAN-only Diagnostic Bundle for some Fiat and Alfa Romeo cars (Single PC)

MultiECUScan CAN-only Diagnostic Bundle for some Fiat and Alfa Romeo cars (Single PC) - only £112.94 including VAT & UK delivery!www.gendan.co.uk

Congratulations! I found the most difficult bit was getting the computer to link with the interface - bearing in mind I bought the multiplex version where some of the settings are different. However, read the instructions and persevere and if all else fails there are many on here who've done it so don't feel embarrassed to ask for help. Once it's all set up it's a doddle to wake it up each time. Then all you've got to do is learn what all the info actually means!I've just ordered it

Sorry, I didn't address that. raising the car is possible with the car's own jack but I don't like doing it because the offering that comes with the car is usually pretty unstable also some don't really lift the car high enough. Therefore a trolley jack is to be preferred and makes things much easier. Personally I find the cheapest trolley jacks, often around the £25 to £30 range, very frustrating to use because they don't have a very great range of lift so you can't get much extension on the axle stands and sometimes won't go under lower cars at all. Something like this: https://www.machinemart.co.uk/p/ctj2l-2-tonne-long-diy-trolley-jack/ is probably about as small as you would want to go to be useful. I have a couple of "breakdown" jacks (small enough to lift easily in and out of a vehicle) which have a 410mm max lift and I wouldn't want to go much smaller. When at home I have a couple of larger ones, like the low entry one I posted a link to above but you're only going to want to invest in something like that if you're going to be using it a lot. Here's a picture of the "breakdown" jacks with my old, more heavy duty, workshop jack in the background. You can see the workshop jack is much more stable due to it being wider and look at the length of the arm? This lets it lift quite a bit higher.

View attachment 430498

This is the modern version of my Breakdown jacks: https://www.sealey.co.uk/product/5637173115/3-tonne-long-reach-heavy-duty-trolley-jack It actually uses the same pumping element and ram as my older jacks do - I bet they're all made somewhere in China - but is slightly higher in the "down" position although it gains a little therefore when extended. Trouble is at this price you can buy a proper workshop 2/3 ton jobbie for only a little more which is probably the better option unless you're dragging it around in your boot.

How easy is it? Well, for someone with experience it's pretty easy. BUT, if you've no experience - and I guess that's you? or you wouldn't be asking? Then the problem becomes where to put the jacking pad and then where to position the axle stands. The good news is you can jack up one side and position the stand then go round to the other side and repeat until you have both front - or both rear - wheels off the ground. Where to position the jack pad and axle stands is always the problem and is a constant source of comment and disagreement on the forum. You can jack directly on the reinforced jacking points - on the sills of most modern vehicles, often indicated by a wee pressed in mark on the sill - and a jacking "puck" can be very useful to stop the jack slipping and minimize damage to the paintwork on the sills: https://www.ebay.co.uk/itm/134040307021?hash=item1f356cc54d:g:To0AAOSwFIdhRFvg&amdata=enc:AQAIAAAA4MAw+ao6aZ47UXYF28+vBZdLBc43aeiQIsVxt5lXLQmO2kTm7ErWZKUuBx9x9gApleDTuLp43y4vYicvBq2rizTxB4wde8REDNQlx8ihNcZfTbPOBm9M0rg0Q7z/6GNxNDQoBc/d3ds+X4WA+oY1lNhwXgxWtHfOUhqnfuucPx+dNU/tadp2caYOpXINZCoee7O98NEpTcUPdxW4Yf5fILYp2DOA5VoQNTwuK2rIEiF51EhoN8K4TOeDDWvENemfm4rECrK2uK741BYWnPhKeCxe+L1cjbM+54AhbnqqC+1n|tkp:BFBMzt_MhNti

Where to place the stands though? Well, definitely nowhere on a flat floor panel, it'll never take the weight. I tend to choose either a major box section under the floor or the engine subframe if working on the front end. One thing I strongly advise against is never to jack the rear end up in the middle of the rear axle. It might bend, especially when the vehicle gets older and corrosion weakens it, and it only takes a small bend in it to destroy the rear suspension geometry which will mean a new axle will be needed. I also like to put a block of wood on the stand where it contacts the car to minimize damage to underseal etc but also it tends to allow the metal of the car to "bite" into it which helps stop it slipping - Safety first always! Never, NEVER get under anything supported only on a jack. If it fails, and they can fail catastrophically quickly, it's a painful way to die.

Here's some pics of Becky's nether regions and my home made jack adapter which I made to spread the load when jacking on the sills. In many years of use I've never damaged a sill yet - oops, shouldn't have said that should I?

View attachment 430494View attachment 430493View attachment 430492

In the last image you can see how the axle stand has a wee wooden block between it and the box section, at the rear, I'm supporting the car on. Here's a couple where you can see where I've placed the stands when working on the front. Again, notice the wooden blocks:

View attachment 430496

View attachment 430497

Of course it's only sensible to check the sills for rust before you start jacking it up and take it easy for the first few strokes, listening as you go for crackling crunchy noises which might indicate the sills are weak and starting to collapse.

Hope that helps a little. Sorry for the pictures maybe not being that illustrative but I originally took them to illustrate the brake work i was doing on the car, not specifically to illustrate jacking practices.

This post contains eBay links which may earn a commission at no additional cost to you.

Sorry, I didn't address that. raising the car is possible with the car's own jack but I don't like doing it because the offering that comes with the car is usually pretty unstable also some don't really lift the car high enough. Therefore a trolley jack is to be preferred and makes things much easier. Personally I find the cheapest trolley jacks, often around the £25 to £30 range, very frustrating to use because they don't have a very great range of lift so you can't get much extension on the axle stands and sometimes won't go under lower cars at all. Something like this: https://www.machinemart.co.uk/p/ctj2l-2-tonne-long-diy-trolley-jack/ is probably about as small as you would want to go to be useful. I have a couple of "breakdown" jacks (small enough to lift easily in and out of a vehicle) which have a 410mm max lift and I wouldn't want to go much smaller. When at home I have a couple of larger ones, like the low entry one I posted a link to above but you're only going to want to invest in something like that if you're going to be using it a lot. Here's a picture of the "breakdown" jacks with my old, more heavy duty, workshop jack in the background. You can see the workshop jack is much more stable due to it being wider and look at the length of the arm? This lets it lift quite a bit higher.

View attachment 430498

This is the modern version of my Breakdown jacks: https://www.sealey.co.uk/product/5637173115/3-tonne-long-reach-heavy-duty-trolley-jack It actually uses the same pumping element and ram as my older jacks do - I bet they're all made somewhere in China - but is slightly higher in the "down" position although it gains a little therefore when extended. Trouble is at this price you can buy a proper workshop 2/3 ton jobbie for only a little more which is probably the better option unless you're dragging it around in your boot.

How easy is it? Well, for someone with experience it's pretty easy. BUT, if you've no experience - and I guess that's you? or you wouldn't be asking? Then the problem becomes where to put the jacking pad and then where to position the axle stands. The good news is you can jack up one side and position the stand then go round to the other side and repeat until you have both front - or both rear - wheels off the ground. Where to position the jack pad and axle stands is always the problem and is a constant source of comment and disagreement on the forum. You can jack directly on the reinforced jacking points - on the sills of most modern vehicles, often indicated by a wee pressed in mark on the sill - and a jacking "puck" can be very useful to stop the jack slipping and minimize damage to the paintwork on the sills: https://www.ebay.co.uk/itm/134040307021?hash=item1f356cc54d:g:To0AAOSwFIdhRFvg&amdata=enc:AQAIAAAA4MAw+ao6aZ47UXYF28+vBZdLBc43aeiQIsVxt5lXLQmO2kTm7ErWZKUuBx9x9gApleDTuLp43y4vYicvBq2rizTxB4wde8REDNQlx8ihNcZfTbPOBm9M0rg0Q7z/6GNxNDQoBc/d3ds+X4WA+oY1lNhwXgxWtHfOUhqnfuucPx+dNU/tadp2caYOpXINZCoee7O98NEpTcUPdxW4Yf5fILYp2DOA5VoQNTwuK2rIEiF51EhoN8K4TOeDDWvENemfm4rECrK2uK741BYWnPhKeCxe+L1cjbM+54AhbnqqC+1n|tkp:BFBMzt_MhNti

Where to place the stands though? Well, definitely nowhere on a flat floor panel, it'll never take the weight. I tend to choose either a major box section under the floor or the engine subframe if working on the front end. One thing I strongly advise against is never to jack the rear end up in the middle of the rear axle. It might bend, especially when the vehicle gets older and corrosion weakens it, and it only takes a small bend in it to destroy the rear suspension geometry which will mean a new axle will be needed. I also like to put a block of wood on the stand where it contacts the car to minimize damage to underseal etc but also it tends to allow the metal of the car to "bite" into it which helps stop it slipping - Safety first always! Never, NEVER get under anything supported only on a jack. If it fails, and they can fail catastrophically quickly, it's a painful way to die.

Here's some pics of Becky's nether regions and my home made jack adapter which I made to spread the load when jacking on the sills. In many years of use I've never damaged a sill yet - oops, shouldn't have said that should I?

View attachment 430494View attachment 430493View attachment 430492

In the last image you can see how the axle stand has a wee wooden block between it and the box section, at the rear, I'm supporting the car on. Here's a couple where you can see where I've placed the stands when working on the front. Again, notice the wooden blocks:

View attachment 430496

View attachment 430497

Of course it's only sensible to check the sills for rust before you start jacking it up and take it easy for the first few strokes, listening as you go for crackling crunchy noises which might indicate the sills are weak and starting to collapse.

Hope that helps a little. Sorry for the pictures maybe not being that illustrative but I originally took them to illustrate the brake work i was doing on the car, not specifically to illustrate jacking practices.

Thanks @Pugglt Auld Jock, that is a great explanation and post.

I’ve just measured the ground clearance for the Panda and it’s about 250mm or 10” in old money, lol.

So I’ve been looking at trolley jacks per your post, I need a jack anyway as I bought a spare wheel from a forum member last month so that £53 trolley jack you linked to would be ideal to stick in the back of the car but it only lifts up to 378mm, would that be high enough to get underneath the car to access the sump plug do you think or would I be better off buying a trolley jack with a higher lift and the appropriate sized (height) axel stands?

The car would only be approximately 120mm higher with that jack or 6” at most, I’m a plumber and used to working in confined spaces but a bit of extra room is always much better but I presume the car being lower off the ground is much safer?

Thanks

Tony

This post contains eBay links which may earn a commission at no additional cost to you.

Hi Tony. I suppose your choice of jack needs to be compared with the axle stands you're thinking of buying. Obviously the absolute minimum would be to ensure you've got a jack that can raise the car far enough to get the stands underneath when in their lowest position. Be careful though because some of these smaller jacks achieve a reasonable max height by having an extended saddle height when in the down position. Look at this one and you'll see what I mean: https://www.ebay.co.uk/itm/234779038314?epid=14026655067&hash=item36a9ebd26a:gThanks @Pugglt Auld Jock, that is a great explanation and post.

I’ve just measured the ground clearance for the Panda and it’s about 250mm or 10” in old money, lol.

So I’ve been looking at trolley jacks per your post, I need a jack anyway as I bought a spare wheel from a forum member last month so that £53 trolley jack you linked to would be ideal to stick in the back of the car but it only lifts up to 378mm, would that be high enough to get underneath the car to access the sump plug do you think or would I be better off buying a trolley jack with a higher lift and the appropriate sized (height) axel stands?

The car would only be approximately 120mm higher with that jack or 6” at most, I’m a plumber and used to working in confined spaces but a bit of extra room is always much better but I presume the car being lower off the ground is much safer?

Thanks

Tony

Another thing to take into account is whether you might later want to tackle more than just an oil change and maybe fitting a new set of brake pads. For instance, how about replacing a rusty exhaust section? You'll quickly find that this job is much easier if you can get the car a good way up in the air and you may then wish you'd bought a jack with a higher lift. It's surprising how much difference just a few more inches can make when you're trying to wiggle a pipe around a back axle or other obstruction.

If you're going to get into anything moderately serious then something like this: https://www.ebay.co.uk/itm/404515099726?hash=item5e2efa944e:g:wlkAAOSwsHplEosc would make a lot more sense - but quite a lot more expensive. I'm not especially saying you should buy this make as it's an unknown manufacturer to me but the size of the jack, the low entry height (80mm) and lifting up to 465mm makes it very versatile. By the time you buy a small jack and then find later on that you could really do with more lift so buy another small jack but with a bigger range of lift you'll have spent as much as what you would if you just go immediately for something like this.

Herts Hillhopper's kind comments about my post above - the one with the pictures of the jack and stands in use - have made me think about doing a guide on this subject. I've not done a "proper" guide before so I'm deep in thought about it. If the weather holds tomorrow I'm going to mess about with Becky (Panda) and Twinkle (Ibiza) and see what I can come up with by way of illustrations. Depending on how that goes I may carry on and do a guide of basics for lifting and supporting small vehicles.

I've been having a wee look through the guides and I don't think anyone else has done one on this subject yet? and it's a subject which comes up periodically when new, less experienced people join the forum. Any of the "old hands" aware of a guide which covers this?

This post contains eBay links which may earn a commission at no additional cost to you.

- Joined

- Mar 20, 2015

- Messages

- 150

- Points

- 99

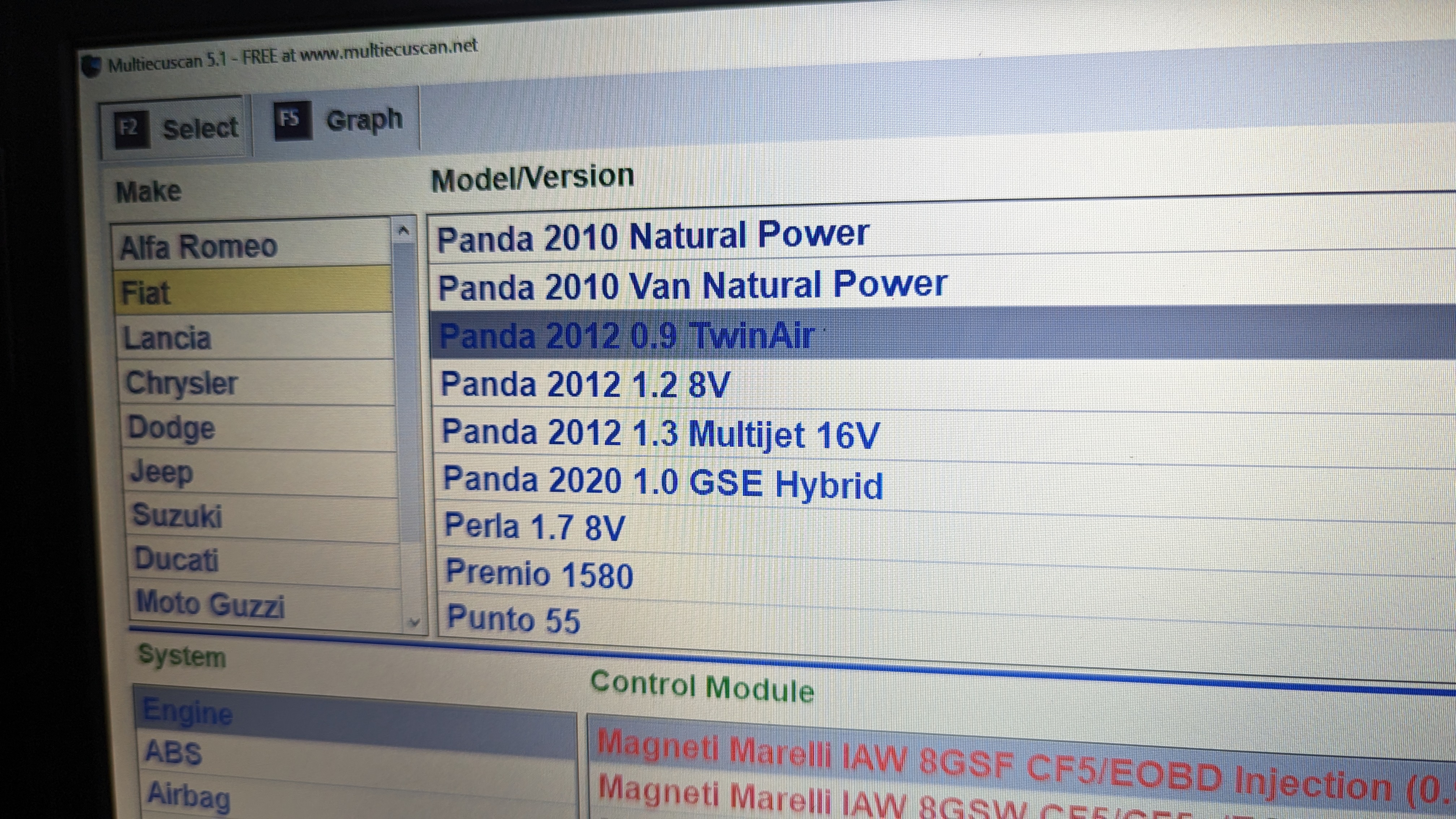

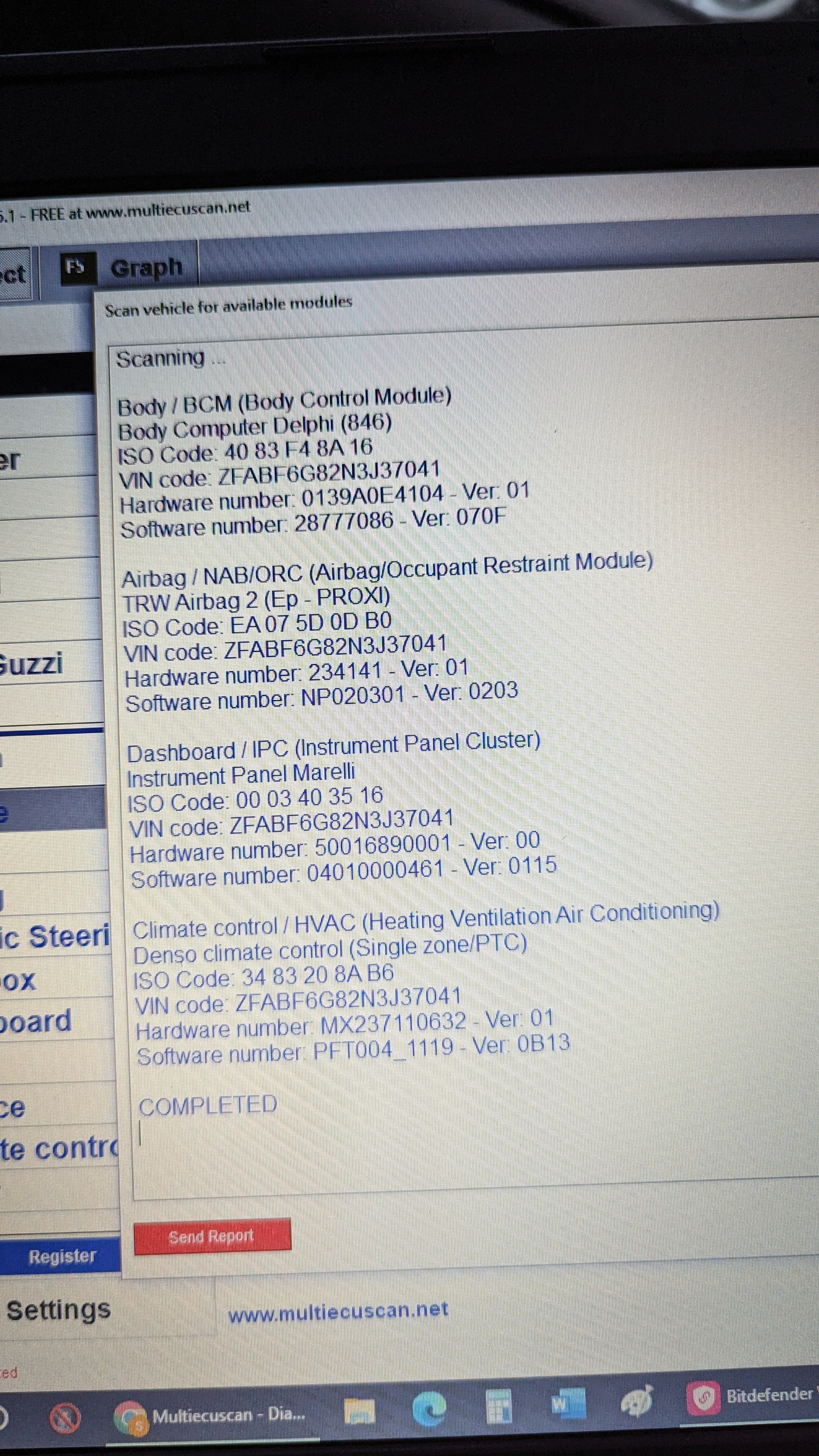

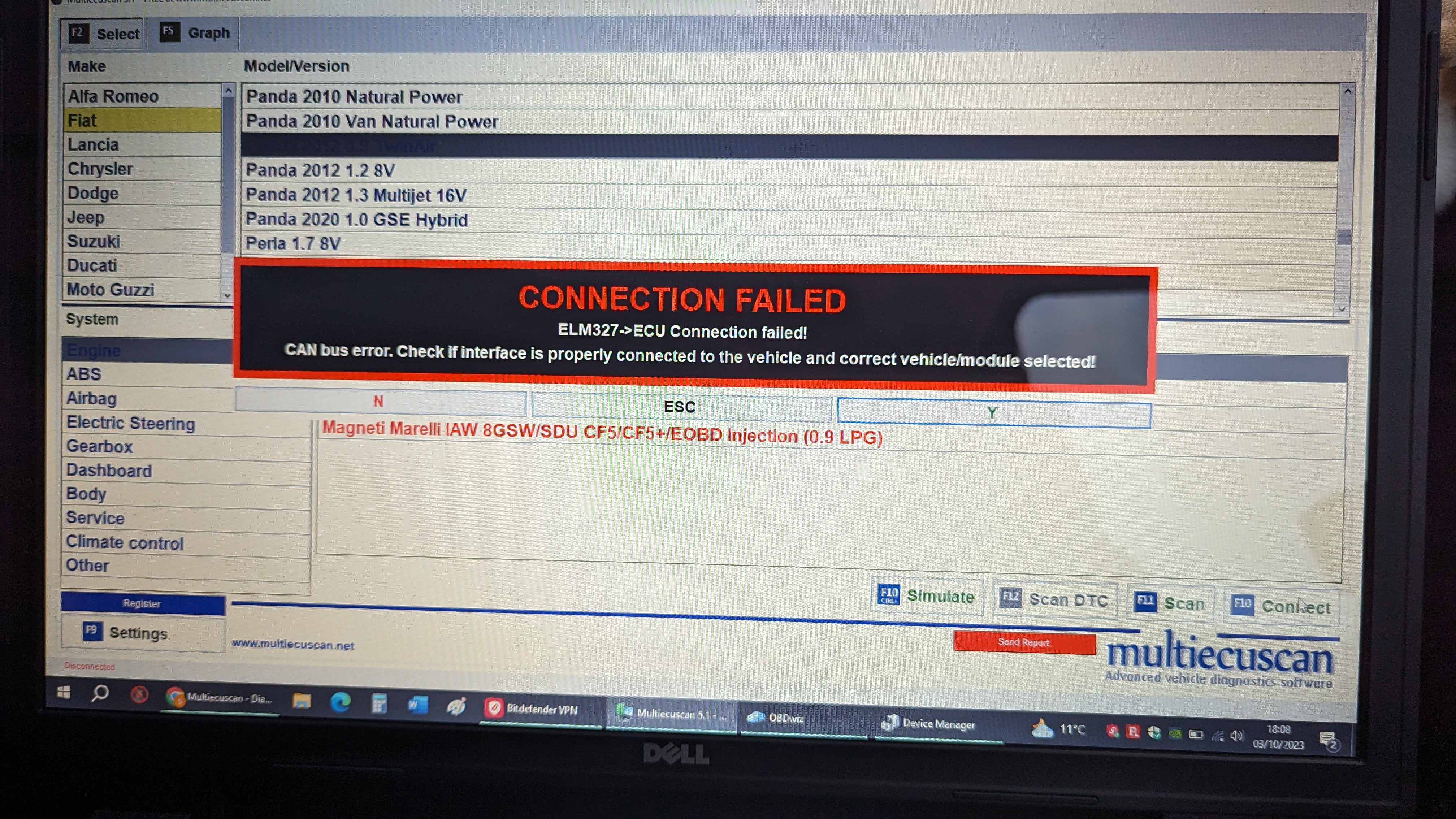

I just got my kit. Took an hour to get my head round the connections and installation of drivers etc. I'm still waiting on a registration code so I used free version in the meantime. It managed to do a scan ok but when connecting up it failed. Only option for closed car type is Twinair 2012. Tried it with engine on and ignition on and no luck. Everything was done per the user guide

Last edited:

It would appear you are trying to connect to the engine ECU on a 2012 Panda 0.9 Twin air which if you look at the list of compatible vehicles on the MES websites https://www.multiecuscan.net/SupportedVehiclesList.aspx you'll see that this is done using the ELM cable with NO adaptor. You have the yellow adaptor plugged in which is for accessing the Airbag and body computer going by that link. Unplug the adaptor connect the red lead directly to the car and it should work.

Use the guide on the website link above to find out which modules need the yellow adaptor, then make a little card with those notes on it so you know when to use it.

Use the guide on the website link above to find out which modules need the yellow adaptor, then make a little card with those notes on it so you know when to use it.

- Joined

- Mar 20, 2015

- Messages

- 150

- Points

- 99

Thanks Andy, I'll give this a try. The list I found said it needed both which is why I tried this initiallyIt would appear you are trying to connect to the engine ECU on a 2012 Panda 0.9 Twin air which if you look at the list of compatible vehicles on the MES websites https://www.multiecuscan.net/SupportedVehiclesList.aspx you'll see that this is done using the ELM cable with NO adaptor. You have the yellow adaptor plugged in which is for accessing the Airbag and body computer going by that link. Unplug the adaptor connect the red lead directly to the car and it should work.

Use the guide on the website link above to find out which modules need the yellow adaptor, then make a little card with those notes on it so you know when to use it.

- Joined

- Mar 20, 2015

- Messages

- 150

- Points

- 99

When I finally took the plunge and decided to invest in MES I really toiled with what version to buy. By that time I'd been using the Volkswagen laptop based scanner VAG-COM (now VCDS) for a number of years on our VAG stuff and got used to being able to communicate with all the modules through just the one interface so, after a bit of soul searching because of the price, I decided to go with the multiplex version of MES. It was relatively expensive but it gives me the ability to very easily start every major service with a complete vehicle scan which I like to do as I know then if there are any unexpected issues to be dealing with. Also, when I've completed working on the vehicle, if any dashboard lights pop up it probably relates to something I've been doing so makes rectification much quicker - wouldn't be the first time I've failed to reconnect a sensor or actuator! If I had to fiddle about with all the different connectors I doubt if I'd bother. So, for me, and at a cost, the multiplex has been a good buy.Thanks Andy, I'll give this a try. The list I found said it needed both which is why I tried this initially

Well, I spent most of today doing the guide on raising and supporting a vehicle. Did the photos in the morning and got slightly wet but missed the heavy rain which came later. Wrote it up this afternoon and posted it for approval about an hour ago. Now excited waiting to see if it appears in the guides section.Thank you. That’s a really useful post and merits being moved to the guides section for all to see.

Its online - here: https://www.fiatforum.com/guides/ra...s-ie-cars-some-thoughts-and-observations.922/ - and very good.Well, I spent most of today doing the guide on raising and supporting a vehicle. Did the photos in the morning and got slightly wet but missed the heavy rain which came later. Wrote it up this afternoon and posted it for approval about an hour ago. Now excited waiting to see if it appears in the guides section.

Nice to see my technique of one side up on the kerb makes an appearance. And I can vouch for ramps used on a downward-sloping drive too- done that as well (which means the car is raised up but – depending on the slope - remains more level than if jacked)

Last edited:

The list..Thanks Andy, I'll give this a try. The list I found said it needed both which is why I tried this initially

Supported vehicle list on the MES website..

Gives a "code" for the cables required for each module

Looks like you set.up far better than I did though

If I stop just before the front wheels are at the top of the ramp the car is dead level and I do that to check gearbox oil level. On the Ibiza the level plug is half way up the diff casing so you've got to get under to check it. The Panda is oh so much easier. Glad you liked my literary efforts, thank you kind sir.Its online - here: https://www.fiatforum.com/guides/ra...s-ie-cars-some-thoughts-and-observations.922/ - and very good.

Nice to see my technique of one side up on the kerb makes an appearance. And I can vouch for ramps used on a downward-sloping drive too- done that as well (which means the car is raised up but – depending on the slope - remains more level than if jacked). A really good guide and a valuable resource for all to use.