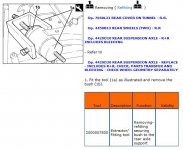

here is the Fiat Service News Bulletin about the Stilo bushes replacement....

Thank you very very much. :worship:

A definitive answer at last. :slayer:

here is the Fiat Service News Bulletin about the Stilo bushes replacement....

Well, surprise, surprise, I got a phone call from the woman at Klann UK today..................

To say that she hadn't had a reply from Klann Germany yet.

Bit of deja vu there - if you think back to when you considered making a wind back tool for the rear brakes - and then found Fiat sold a tool for peanutsThanks for the info Davren. I'm sure yours is of infinitely superior quality

Bit of deja vu there - if you think back to when you considered making a wind back tool for the rear brakes - and then found Fiat sold a tool for peanuts

Darven.

I spoke to a Fiat dealer this morning about how they replace the bushes.

Most do reduce the interference fit, wouldn't say how or if it was the bush or the subframe but I had the feeling it was the subframe(reamed to suit). Use the kit you brought and a very large three legged flywheel extractor. I was asked not to mention the name of the dealer or the machine shop they send them to but I think I finally have a few answers:

1. The bore in the subframes vary with model and age so the bushes are supplied at the larger end of the scale.

2. Reduce the interference fit(or buy a £20,000 press and specialised tool)

3. cut out the old bush, use the Fiat kit and Large fly wheel extractor(large thread) to press the new one in.

All seems a bit simple but he asured me that was how it was done?

After they described the tool to me I was wrong to call the device a "Flywheel Extractor". I found out this morning its called a "Hydraulic Puller".

Its used the same way but is capable of delivering forces of over 10 ton and has a reach of 300mm.

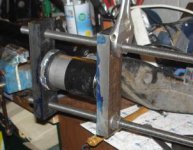

I found a similar one on ebay and I've attached a pic of it.

http://cgi.ebay.co.uk/Sealey-Triple-Leg-Hydraulic-Puller-10tonne-/150345508919

Interesting, but I think £135 delivered is a bit expensive for something that may work and is only likely to be used once.

When I do mine, I'm going to start off by trying the cheapest option first, i.e. the Fiat three pronged press piece (or my homemade one) and threaded rod then progress on from there if (when?) it doesn't work.

The bush is around 61mm diameter

If it's any help, you don't need to guess with the interference fits

http://www.tribology-abc.com/calculators/e6_2.htm

This is a useful interference fit calculator which will show the resistance to torque and friction forces for different fits

Anything more than a heavy interference fit isn't precision engineering but pure dockyard. The bush is around 61mm diameter