Gandalf500

Member

Hi there,

My 500 has suddenly developed an engine problem.

It started yesterday, a sort of whistle sound, it would happen when i accelerated with clutch engaged.

today it suddently got a lot worse.

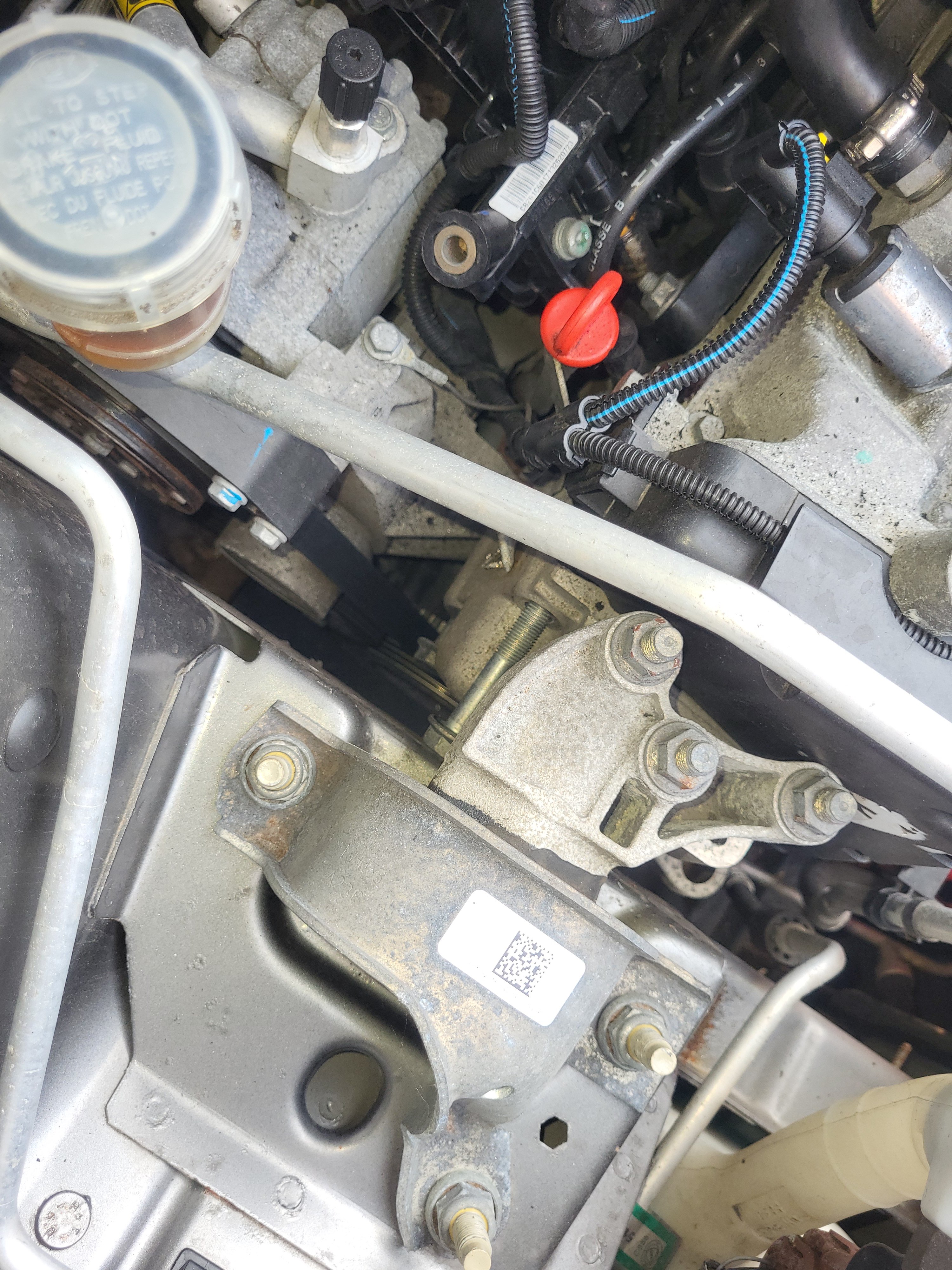

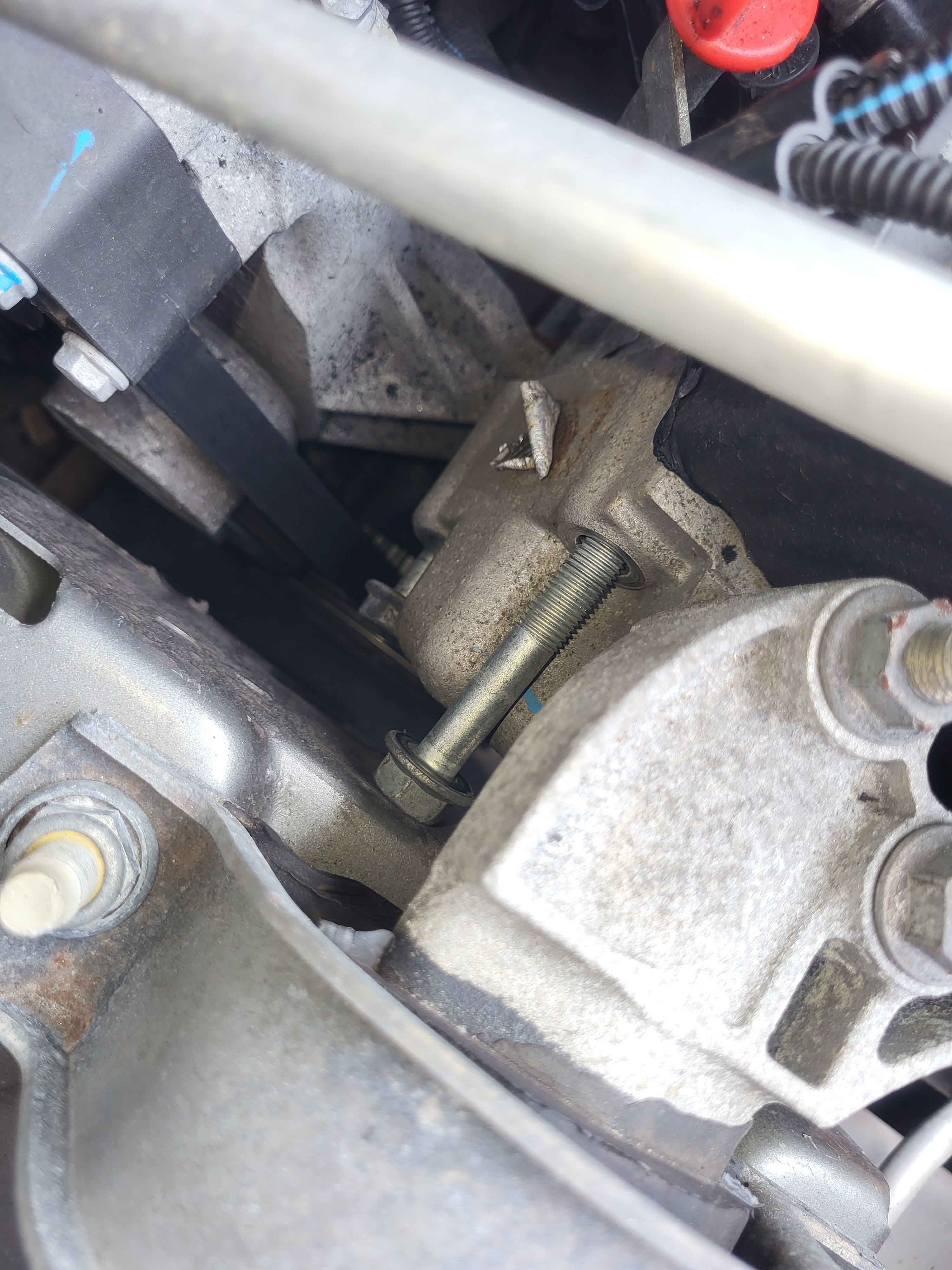

It sounds like a knocking rattling, whistling sound. And i could feel the knocking through my foot and throughout the car. I thought the exhaust came off or something. I managed to get home. I had a look at the engine and noticed the below bolt hanging out, also looked like the belt behind was wobbling.

anyone got any advice, I'm going to get it to a garage, but would be nice to gett some advise before hand.

My 500 has suddenly developed an engine problem.

It started yesterday, a sort of whistle sound, it would happen when i accelerated with clutch engaged.

today it suddently got a lot worse.

It sounds like a knocking rattling, whistling sound. And i could feel the knocking through my foot and throughout the car. I thought the exhaust came off or something. I managed to get home. I had a look at the engine and noticed the below bolt hanging out, also looked like the belt behind was wobbling.

anyone got any advice, I'm going to get it to a garage, but would be nice to gett some advise before hand.