Ok here’s more to add to my now finished project and finally finished

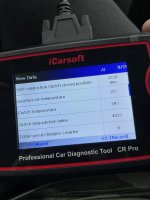

Here’s the codes that I faced this month

P0856 - VDC messages (from CAN)

P0703 - Service brake switch (from CAN)

P0805 - Clutch sensor

P0942 - Hydraulic circuit pressure

P2908 - Clutch sub-system

So first I changed the brake switch that in return got rid of po703

I drained the transmission fluid from large reservoir and filled half way with cs speed

I then bled the clutch dot 4 and used new fluid and bled the system in

multiecuscan

Don’t forgot to depressurise first

I changed gear box oil put back in 3.0 litres

Which after all this I was left with 2 codes

Being po856 po805

So then my idea was to start removing the selespeed harness from each sensor and plug to see what code was thrown that way ruling out each has I go

To which I got to the master slave cylinder clutch position sensor once removed I got no code at all

So I had remove the good looking bracket that holds the reservoir tank on the robot to get to this sensor 10 min job once headlight and top of filter and fuse box off

So I removed the sensor inspected it and I had a broken contact on the 3rd pin it was bent and cracked

Again causing short circuit

Changed for new put all back together both codes was gone didn’t have to clear them

Then in

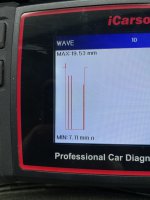

multiecuscan I did delete statistical data then carried out clutch drain 3 times

Then last the end of line calibration which does actually do everything including calibration of sensors once new fitted

That’s it job complete no more issues

Gear box said calibration ok

Was very very smooth no noises even when selecting gear I had to watch the dash to see it moving to first because had no sound

Drives brilliant so I’m extremely happy I did all the extra work and full service on the selespeed . Because I’m in 80k miles now I will change the actuator oil tank and seals giving that extra protection for future then every year I will change and bleed clutch fluid and 2 years transmission

Got to keep on top of a service with a comfortmatic

Love the gearbox these are the first issues I’ve faced with a comfortmatic and both times in 2022 and now was wiring shorts and sensors

First things to check anyone dropping on this thread. Remove selespeed harness clean all contacts

Check gear sensor , clutch sensor , and the 4 plugs on the rear of the gearbox bang in front of under floor battery tray you have Evo0 , Evo1 Evo2 Evo3 always check Evo1 plug

Change clutch dot 4

But it’s shite about seals dissolve to make it dark or black just go on every 2 year max

When they build this selespeed these use the electrical contact greese for seals etc and once it mixes with dot4 it changes colour of it that’s all after so long

Next check brake switch and rev throttle position has if to fast that causing issue when selects gear

Check brake bulbs

Check gear to chassis strap or fit 2

98% of problems are sensors and wiring

If these don’t work it’s the slave or clutch bearing

While box off fit full clutch kit

Good luck that’s the last to add to this thread

Some videos coming