Extra info. Not so DIY anymore.

20. Temporary fix, hack job. In emergency you can (if you know what you're doing, you're familiar with using abrasives, and how it affects geometry) skim the valve stem tips (when shims cannot be any thinner) and drive a car for a while. It may be case hardened, so machining this layer off is risky (quick wear and/or cracks).

21. Grinding shims is NOT a good idea too. Surface grinding process has many potential defects waiting to "bite" you. Such as distortion, deformation due to overheating. Example of improper grinding job (tiny animated GIF - forum has weird restrictions on GIF size 488 kilo, while other formats can waste megabytes of space). Good shims are flat, and don't spin on surface plate.

22. Folks, remember. Just because you throw something on the surface grinder, doesn't make it "perfect" by any means. Hack (clown) can produce uneven thickness shim (in this example it's visible, but not always). It can be off, for example by 0,01-0,03 mm easily (to that, add other defects like concave shape). It requires a master "grind hand" to do such "simple" job properly!

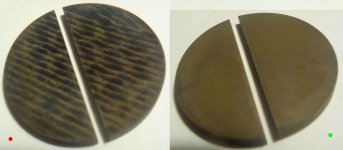

23. If you ever order a custom, ground shims (modified stock ones), only one side can be altered, and that side must go into tappet (camshaft must ride on the original surface, smoother, harder). Acid etching reveals roughness (mechanical and chemical inconsistency) of the surface ground shim (weird "texture" on the left, potential cracks will start exactly right there, stress concentration).

24. Most (if not all) shims are case/induction hardened, and grinding may damage this "skin" (+ other defects mentioned earlier). This is DIY metallographic examination (you can do it at home, with almost any acid). Cross-section of the shim after grinding. Light layer is slightly thinner on one side (that's the processed, altered one). If possible use only original shims, commercial, not "tweaked", custom made.

> Video introduction to Metallography (can't post live link): www youtube com/watch?v=fc8zrgYJCJw

So be careful, some of the "professional" engine repair shops are straight clowns.