No worries, I will get it somewhere

But I am almost certain that in this car it will not be my permanent ECU. What follows is that I will probably not get the car to the dyno with this ECU. But I want to master it to the point of being sure I can use this ECU with no problem on another project, if any.

The problems I had with the fuel made me study the program a bit more. Earlier I found the after start enrichment, now I also see how the load delta enrichments work. Earlier I assumed that whatever settings are there they would just work, but now this means I can start correcting chocking on acceleration if correcting the main VE map does not help (and so far it seems that's indeed the case). Only it is tricky - one map has to be done on cold engine, kind of difficult to keep driving and testing the behaviour and keep the engine cold

Probably dumping an industrial size bag of ice in the engine bay and dropping some cubes in the expansion tank would help

.

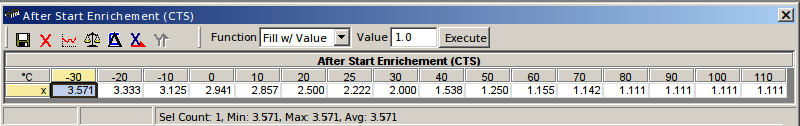

And, I also checked the values of after-start enrichements of the 18F ECU, they are way way smaller, at -40 degrees CTS it uses 217% of the default fuel, not ~350%

Small valves in the 1.1 MPI engine not allowing all the after start fuel to get into the cylinders, or what?

It was right under my nose, only the values in it are so extreme that I was not paying attention to it. Can anyone explain to me why it needs to be so drastic (double the fuel at relatively warm engine conditions, almost quadruple it when really cold) for the factory 1.1 MPI engine? Note that this is over the regular cold engine fuel enrichment, which in itself adds a lot already...

It was right under my nose, only the values in it are so extreme that I was not paying attention to it. Can anyone explain to me why it needs to be so drastic (double the fuel at relatively warm engine conditions, almost quadruple it when really cold) for the factory 1.1 MPI engine? Note that this is over the regular cold engine fuel enrichment, which in itself adds a lot already...