Good morning all, I wonder if anyone can offer up some advice..?

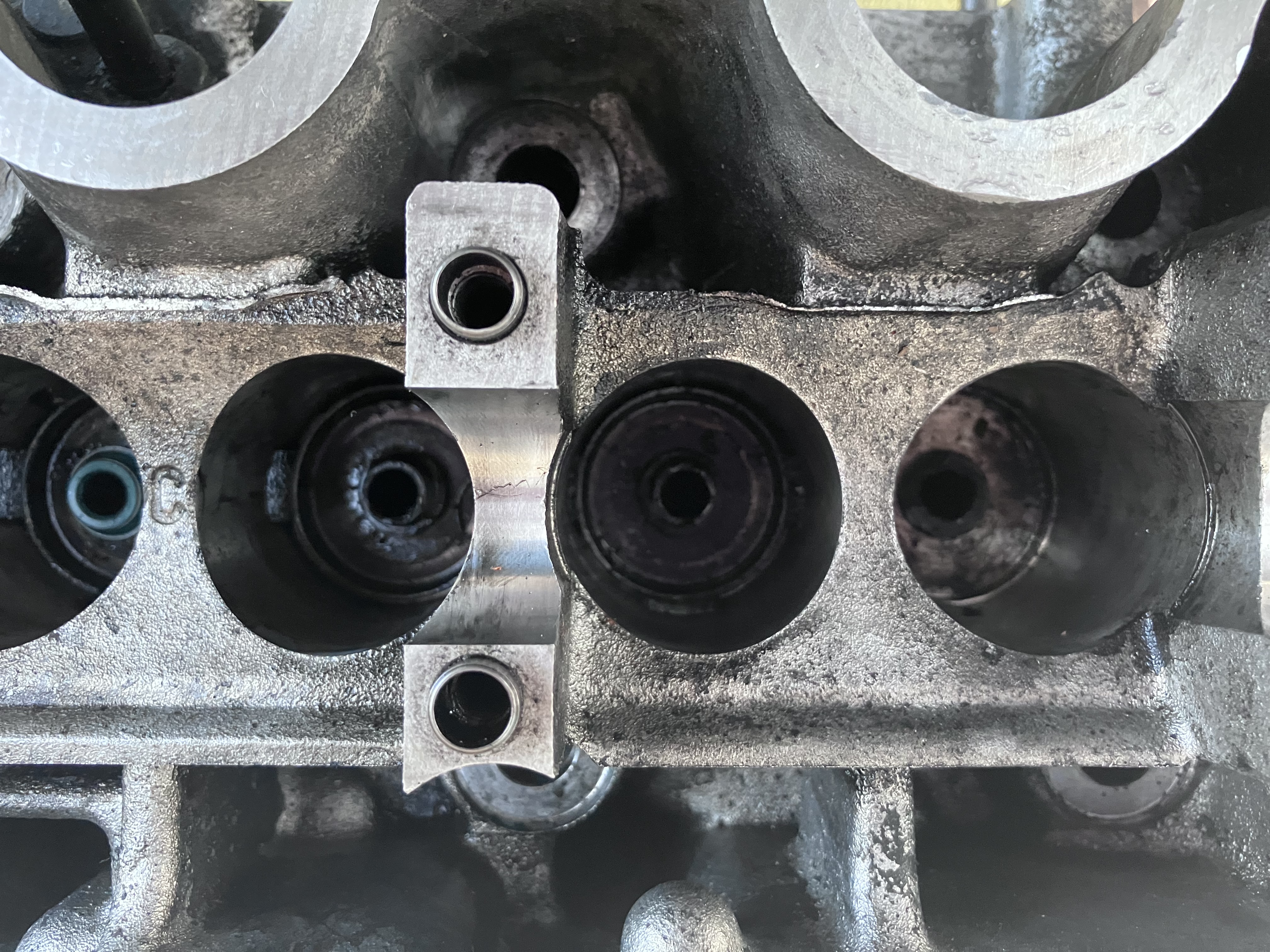

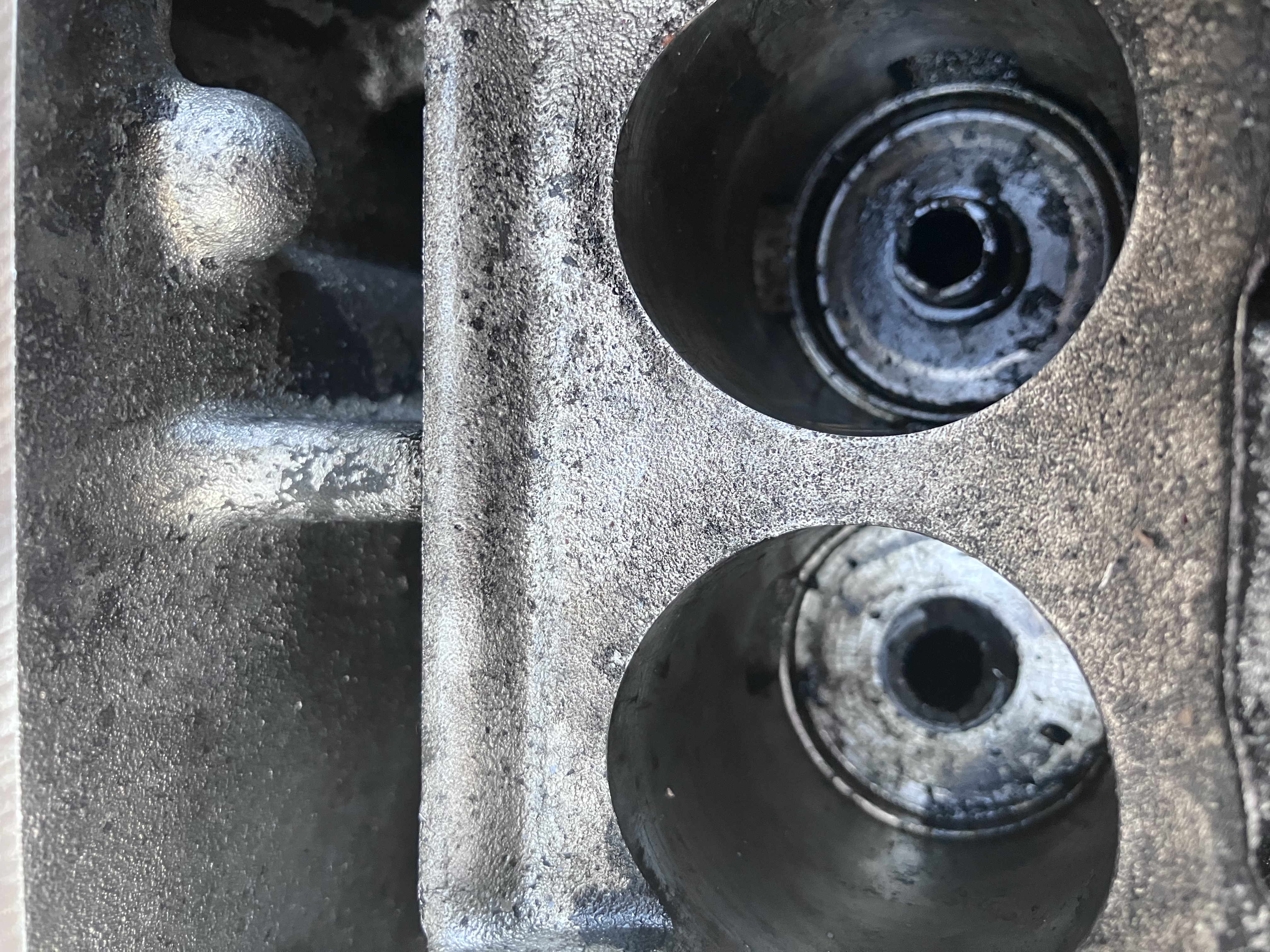

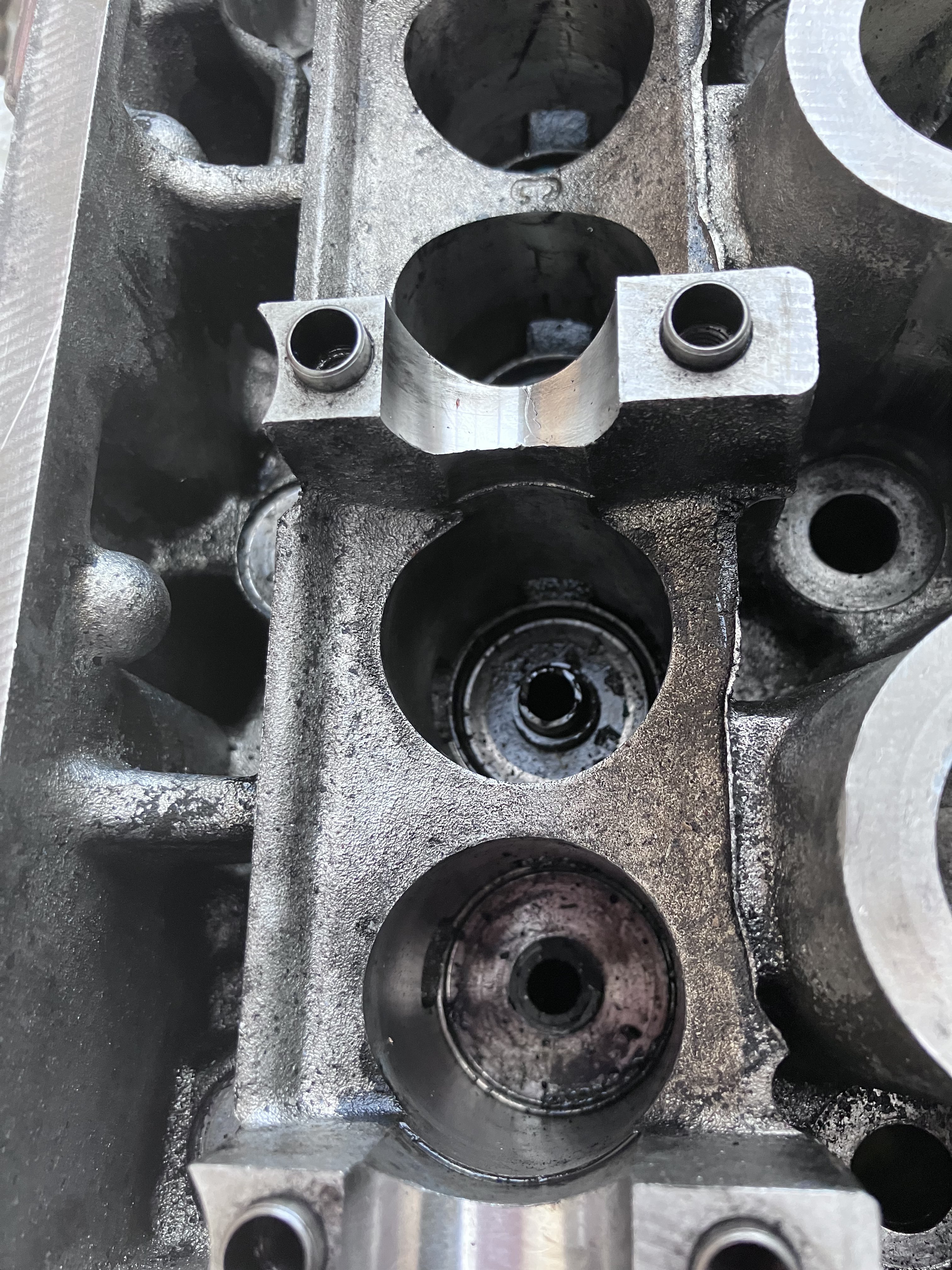

We have a situation with a multipla engine… and we’re not sure where to go to sort it out. Essentially the problem is this; whilst attempting to remove a valve stem, it broke.

We have managed to buy new ones, (& a valve stem puller for future) but what do we do about getting the broken one out?

Would this be something a garage could do, or is it more of an engineering place we need to go to? Or is there a method to getting it out? Any help or advice would be gratefully received! Thanks. (Lots of photos to try and illustrate the problem!)

We have a situation with a multipla engine… and we’re not sure where to go to sort it out. Essentially the problem is this; whilst attempting to remove a valve stem, it broke.

We have managed to buy new ones, (& a valve stem puller for future) but what do we do about getting the broken one out?

Would this be something a garage could do, or is it more of an engineering place we need to go to? Or is there a method to getting it out? Any help or advice would be gratefully received! Thanks. (Lots of photos to try and illustrate the problem!)