reason I never was the que was huge and if i damaged anything id be stuck 70miles from home with a trailer (can get recovered without a trailer easy)

im sure that if my little bella can do it, you could have man'd up and given it a run

reason I never was the que was huge and if i damaged anything id be stuck 70miles from home with a trailer (can get recovered without a trailer easy)

you got some bits to practice on, and get the machine set up?

Good luckk, looking forward to seeing the finished articalwant lots of pictures

haha there was to much telling me not to do it... first worried about the trailer. but got over that... then seen a couple of the turbo cars go bang lolim sure that if my little bella can do it, you could have man'd up and given it a run

good stuff

just reading your thread on the punto forum...

the oil rings on EVERY 16valve ive stripped (one under 40k) have had oil rings in many pieces! I compared them to the 8valve and the 16valve oil rings are much more delicate.

I fitted some very low mileage 8valve oil rings on my engine.

ALSO engine rebuilders can get piston ring sets for around £70 so might be worth asking them. might even be able to get you uprated rings for cheaper then fiats rubbish.

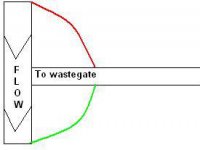

You know about fitting the gate pipe at more than 90 degrees to the flow, dont you.