Done some piston work seeing as I have so many sets.

managed to machine out 6CC of metal dropping the C/R to 9:1

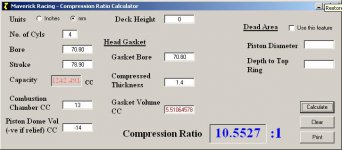

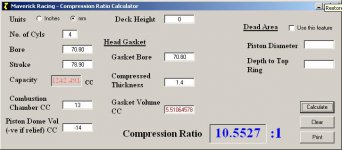

16valve engine combustion chamber dimensions i worked out for anyone thats interested

Standard compression 10.60:1... calculated at 10.5527:1 guess fiat rounded it off... close enough.

piston dish machined out to 20CC (20ml)

managed to machine out 6CC of metal dropping the C/R to 9:1

16valve engine combustion chamber dimensions i worked out for anyone thats interested

Standard compression 10.60:1... calculated at 10.5527:1 guess fiat rounded it off... close enough.

piston dish machined out to 20CC (20ml)

Last edited: