True. The engine runs fine - providing you've got the timing set right of course - even if it's comes up needing the reset. However the CEL will be lit so you'll fail MOT next time round. Also, if you're going to drive around with the CEL lit and ignore it then you may well miss that it's telling you something else much more important and maybe expensive to fix?Same with "phonic wheel reset/adaptation/whatever". It is one of the most useless features in the FES/MES programs.

It does almost nothing (cosmetic changes). It has nothing to do with the engine starting (or not). So forget about it for now.

Clueless people are fixated, obsessed with it (forums are full of "advice" like that: have you done The Reset, do the reset, you must do the reset, your car needs a phonic wheel procedure, learning, reset,...crazy). Engine won't start = phonic wheel reset. Rough idle = phonic wheel reset. Misfire = reset...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Timing issue

- Thread starter Scottieo321

- Start date

Currently reading:

Technical Timing issue

- Joined

- Apr 22, 2018

- Messages

- 1,018

- Points

- 349

The term should not be used here until the OP starts the engine. Then he can fool around with cosmetic touch-up (resets/adaptations etc).

Bad timing (so bad it trips the CheckEngine) has nothing to do with phonic wheel (assuming it is mechanically OK, installed properly).

It (reset/learning procedure) is also NOT a way to "fix" bad timing. By the way (with bad timing +/- one tooth) engine still must start.

Real goal is to have mechanically good timing, not fooling ECU, that timing is "better" (by using software tricks/resets)!

There is a play in the timing tools...and the phonic wheel (before you tighten the bolts)... Plus VVT (another can of worms).

Question: which position is the correct one? Where should I "freeze" the phonic wheel (torque 3 bolts)?

Performing a "phonic wheel learn reset" can do more "harm" than good. You don't know which way you're fooling the ECU.

Don't do it for the sake of doing it. Just because there is an option, doesn't mean you "must" use it (monkey see, monkey click buttons).

Bad timing (so bad it trips the CheckEngine) has nothing to do with phonic wheel (assuming it is mechanically OK, installed properly).

It (reset/learning procedure) is also NOT a way to "fix" bad timing. By the way (with bad timing +/- one tooth) engine still must start.

Real goal is to have mechanically good timing, not fooling ECU, that timing is "better" (by using software tricks/resets)!

There is a play in the timing tools...and the phonic wheel (before you tighten the bolts)... Plus VVT (another can of worms).

Question: which position is the correct one? Where should I "freeze" the phonic wheel (torque 3 bolts)?

Performing a "phonic wheel learn reset" can do more "harm" than good. You don't know which way you're fooling the ECU.

Don't do it for the sake of doing it. Just because there is an option, doesn't mean you "must" use it (monkey see, monkey click buttons).

Last edited:

I see what you're going on about. However there's always been "manufacturing tolerance" in mass production. If this were a performance engine I'd be very unhappy with this amount of variance but for a wee Fiat Fire engine? It's not going to worry me too much if I loose such a small amount of performance I'm not going to notice it or waste a few drops of fuel. I've noticed that that play exists but I have found that if you tighten the 3 bolts until they are just more than finger tight then most of that backlash play goes away - at least it did when I experimented with it.The term should not be used here until the OP starts the engine. Then he can fool around with cosmetic touch-up (resets/adaptations etc).

Bad timing (so bad it trips the CheckEngine) has nothing to do with phonic wheel (assuming it is mechanically OK, installed properly).

It (reset/learning procedure) is also NOT a way to "fix" bad timing. By the way (with bad timing +/- one tooth) engine still must start.

Real goal is to have mechanically good timing, not fooling ECU, that timing is "better" (by using software tricks/resets)!

There is a play in the timing tools...and the phonic wheel (before you tighten the bolts)... Plus VVT (another can of worms).

View attachment 466745

Question: which position is the correct one? Where should I "freeze" the phonic wheel (torque 3 bolts)?

View attachment 466746

Performing a "phonic wheel learn reset" can do more "harm" than good. You don't know which way you're fooling the ECU.

Don't do it for the sake of doing it. Just because there is an option, doesn't mean you "must" use it (monkey see, monkey click buttons).

The Phonic Wheel relearn doesn't "fool" the ECU into anything all it does is instruct the ECU to accept the existing crank/cam position sensor readings as ok and run with them. If the timing is incorrect doing a relearn won't sort it, it must be mechanically correct for that.

I agree with you that our OP needs to get the engine running before thinking about niceties like whether he needs to do a relearn. I do think it would be wise to get the cam timing correct - ie. not one tooth out - so that any poor running is then known not to be due to the timing being out. However I fear it may well turn out there's much bigger problems lurking in this engine from what was said back at the beginning of this thread.

Of course just because the play has been minimised by doing this doesn't mean the tools are correctly positioned, or that the phonic wheel is presenting it's timing aperture in the correct position in relation to piston position in the bore. However if you're going to go looking to eliminate that you're going to need to break out the crankshaft degree wheel and a DTI to read piston position. Unfortunately most of us just have to "play" with the "toys" we've got - Unfortunately it's an imperfect world damn it!I've noticed that that play exists but I have found that if you tighten the 3 bolts until they are just more than finger tight then most of that backlash play goes away - at least it did when I experimented with it.

Scottieo321

Member

So update to the update, all put into place so that the tools line up perfectly. She starts but she's very very shaky (I'll upload the vid) to the point everything inside and out is madly shaking.

Plus side she starts and no engine light either and no errors showing up.

I'm guessing the shaking is something to do with the fuel intake but again I've no clue and not guna start messing till I've got a full indication.

Plus side she starts and no engine light either and no errors showing up.

I'm guessing the shaking is something to do with the fuel intake but again I've no clue and not guna start messing till I've got a full indication.

Attachments

stick the air cleaner and breather pipes back on and see how she goes. Sometimes it can make quite a difference. It would be interesting to hear what she sound like if you give her a bit of a rev up to see what happens under a bit of load.

Scottieo321

Member

Stuck it all back on 100% made all the difference, still quite the shake when idol but not as bad.stick the air cleaner and breather pipes back on and see how she goes. Sometimes it can make quite a difference. It would be interesting to hear what she sound like if you give her a bit of a rev up to see what happens under a bit of load.

Here's another vid along with a few revs.

Attachments

- Joined

- Apr 22, 2018

- Messages

- 1,018

- Points

- 349

Test drive will tell (how the engine is performing under real load, not at idle).

Also OBD2 data + exhaust gas analysis would help to pinpoint the problematic area (is it fuel/air, is it ignition, exhaust leak or what).

Air filter box shaking is "acceptable" in old FIRE units, especially after such "adventures" (bent valves etc.). Not much you can do now.

Combustion process and so on is probably not perfect (something is uneven between cylinders), valves are still not 100% OK etc.

But it will run relatively "fine". Good job reviving it.

Good job reviving it.

Now you can MESs-around with software resets, learning procedures, whatever...

Also OBD2 data + exhaust gas analysis would help to pinpoint the problematic area (is it fuel/air, is it ignition, exhaust leak or what).

Air filter box shaking is "acceptable" in old FIRE units, especially after such "adventures" (bent valves etc.). Not much you can do now.

Combustion process and so on is probably not perfect (something is uneven between cylinders), valves are still not 100% OK etc.

But it will run relatively "fine".

Now you can MESs-around with software resets, learning procedures, whatever...

I'd be tempted to just run it like this for a while and see if it settles down of it's own accord. Always listening out in case something seems to be not doing so well in which case further investigation might be needed. Often, when an engine has had a lot of stuff done to it like this it does take a few miles to settle down.Stuck it all back on 100% made all the difference, still quite the shake when idol but not as bad.

Here's another vid along with a few revs.

Mike1alike

Established member

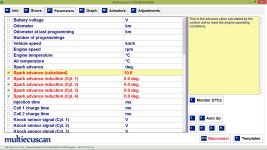

First thing, you should recheck the timing. One tooth off can give you that shake. Check via diagnose tool what value do you have on "Spark advance", "Spark advance reduction".

And since your camshaft pulley has the timing mark, you can check it old school. Check the crankshaft TDC by the flywheel in the flywheel housing at the opposite end of the engine and camshaft pulley should be aligned with the head mark. I marked on your photo the camshaft pulley and the other one is how the flywheel should sit.

Also, I would say the engine support might give that shake if it is worn. But if the engine ran smoothly before you did this repairing, that's not the case.

And since your camshaft pulley has the timing mark, you can check it old school. Check the crankshaft TDC by the flywheel in the flywheel housing at the opposite end of the engine and camshaft pulley should be aligned with the head mark. I marked on your photo the camshaft pulley and the other one is how the flywheel should sit.

Also, I would say the engine support might give that shake if it is worn. But if the engine ran smoothly before you did this repairing, that's not the case.

Attachments

Last edited:

Mike1alike

Established member

P.S.: Did you do the correct valves clearances?

A shakey airbox isn't anything to worry about. I imagine it drives just fine now. Job done?Stuck it all back on 100% made all the difference, still quite the shake when idol but not as bad.

Here's another vid along with a few revs.

What exactly did you do wrong?

Scottieo321

Member

If I put the crank to where the flywheel is at 0 then the engine will not start which is why it's been done with pistons half mast and it's started first time each time.First thing, you should recheck the timing. One tooth off can give you that shake. Check via diagnose tool what value do you have on "Spark advance", "Spark advance reduction".

And since your camshaft pulley has the timing mark, you can check it old school. Check the crankshaft TDC by the flywheel in the flywheel housing at the opposite end of the engine and camshaft pulley should be aligned with the head mark. I marked on your photo the camshaft pulley and the other one is how the flywheel should sit.

Also, I would say the engine support might give that shake if it is worn. But if the engine ran smoothly before you did this repairing, that's not the case.

Don't have any sort of diagnostic tool part from cheap little OBD2 so that's no good unfortunately.

Going to give it a run for a few days see if it's ok or not I'm hoping it is but I'm dare betting there's more damage than can be seen.

Scottieo321

Member

Trying to put it at TDC by the crank and the cam, unfortunately doing with the crank it won't start but having it at half mast it's working which technically as pug and grande said it's TDC +90° and that's getting it going, only time will tell if it runs fine or not but there was plenty wrong with this engine before I got my hands on it.A shakey airbox isn't anything to worry about. I imagine it drives just fine now. Job done?

What exactly did you do wrong?

Scottieo321

Member

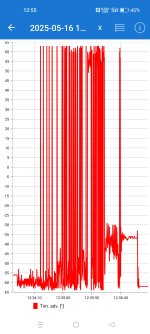

Sooooo after going to start her today I'm getting the shaking back again, I'll upload 2 vids plus some graphs I got from OBD2 reader. The timing advance is -62° when I first turn on which you can see on them I've also put some others don't know if they help or not.

When I rev her a bit after I take foot off she's about to stall but managed not to at last second.

I'm at a stump now but she's still starting lol.

Edit: also add there's still no codes showing.

When I rev her a bit after I take foot off she's about to stall but managed not to at last second.

I'm at a stump now but she's still starting lol.

Edit: also add there's still no codes showing.

Attachments

-

VID20250516124457.mp465.8 MB

-

VID20250516124646.mp470.4 MB

-

Screenshot_2025-05-16-12-55-33-75_1c4cade50911c4021d022fd7fc21ca47.jpg475.4 KB · Views: 41

Screenshot_2025-05-16-12-55-33-75_1c4cade50911c4021d022fd7fc21ca47.jpg475.4 KB · Views: 41 -

Screenshot_2025-05-16-12-56-32-36_1c4cade50911c4021d022fd7fc21ca47.jpg254 KB · Views: 32

Screenshot_2025-05-16-12-56-32-36_1c4cade50911c4021d022fd7fc21ca47.jpg254 KB · Views: 32 -

Screenshot_2025-05-16-12-56-52-68_1c4cade50911c4021d022fd7fc21ca47.jpg211.1 KB · Views: 43

Screenshot_2025-05-16-12-56-52-68_1c4cade50911c4021d022fd7fc21ca47.jpg211.1 KB · Views: 43 -

Screenshot_2025-05-16-12-58-07-21_1c4cade50911c4021d022fd7fc21ca47.jpg227.2 KB · Views: 34

Screenshot_2025-05-16-12-58-07-21_1c4cade50911c4021d022fd7fc21ca47.jpg227.2 KB · Views: 34 -

Screenshot_2025-05-16-12-58-33-83_1c4cade50911c4021d022fd7fc21ca47.jpg262.6 KB · Views: 34

Screenshot_2025-05-16-12-58-33-83_1c4cade50911c4021d022fd7fc21ca47.jpg262.6 KB · Views: 34

Last edited:

Mike1alike

Established member

Your timing is off. Set it old school, as I've mentioned. Without using the timing tools. Put the crankshaft on TDC aligning the flywheel to 0⁰ mark and align the camshaft pulley with the mark on the CH. Using the timing tools you have both crankshaft and camshaft 90⁰ forward TDC, that is why when you tried setting it with crankshaft on TDC and camshaft locked with the tool it wouldn't start, because you got it 90⁰ off. By the pictures you've put it looks ok (both 90⁰ forward TDC) but timing advance -62⁰ says it's not ok. I think the camshaft is behind at least 2 teeth. You don't need to take anything down to set it right, except maybe the engine mount. And you can very easily do it using a bit, like this:

I'm guessing you need to put the bit on the crankshaft pulley and revolve the engine to have the belt skipping. Do it untill they are spot on.

I'm guessing you need to put the bit on the crankshaft pulley and revolve the engine to have the belt skipping. Do it untill they are spot on.

Last edited:

Mike1alike

Established member

PS: no codes is legit because you don't get any code for setting the timing off. But you need to set it right for the engine to run smooth.

Mike1alike

Established member

Scottieo321

Member

Your timing is off. Set it old school, as I've mentioned. Without using the timing tools. Put the crankshaft on TDC aligning the flywheel to 0⁰ mark and align the camshaft pulley with the mark on the HG. Using the timing tools you have both crankshaft and camshaft 90⁰ forward TDC, that is why when you tried setting it with crankshaft on TDC and camshaft locked with the tool it wouldn't start, because you got it 90⁰ off. By the pictures you've put it looks ok (both 90⁰ forward TDC) but timing advance -62⁰ says it's not ok. I think the camshaft is behind at least 2 teeth. You don't need to take anything down to set it right, except maybe the engine mount. And you can very easily do it using a bit, like this:

I'm guessing you need to put the bit on the crankshaft pulley and revolve the engine to have the belt skipping. Do it untill they are spot on.

When the crank is at 0 on the flywheel she doesn't start at all, it's been mentioned previously which is why it's being set with all cylinders at half mast this is the only way she's starting up.

The mark you've said about with the cam is not the TDC mark it's just a bit extra weld on it, if the cam mark is on that it's about -45° from TDC so you cannot get the locking tool in at all.

I know you've said not to use them and set it old school which I understand but some reason if I put it to the TDC marks there's no fire even doing it crank only.

The timing advance is it for both or just the cam or crank?

it might give me some indication as to where to put them for it to be the 10° that your picture shows.

Honestly it's becoming a headache at this point, this is the closest it's come so far for 2 weeks now near enough and it actually starts again, I'll try the method in the video as well see if that makes a difference thanks.

Mike1alike

Established member

The timing advance is for both. That what setting the timing correct means, having both camshaft and crankshaft "timed", synchronized. Technically it's just the crankshaft that hits the TDC in its path back and forth inside the cylinder and you time the camshaft with it so it opens and closes the valves in the right time so that fuel goes inside the combustion chamber right before the spark ignites and then exhaust valve opens to drive out the exhaust gas, doing it time and time again for every cylinder. Since engine is revolving pretty fast, it turns out spark need that advance, to go before piston hit the TDC so the engine can efficiently use that explosion energy.The timing advance is it for both or just the cam or crank?

it might give me some indication as to where to put them for it to be the 10° that your picture shows.

10⁰ is the correct value for my Punto 1.2, I don't think yours should be different. Anyway, -62⁰ is definitely not the correct value. "Spark advance reduction" gives you more info, with timing set right you should have 0.0⁰ SPA on all cylinders. If you physically don't synchronize the cam with the cranck, ECU is adjusting the sparking time as much as it can, reading the knocking sensor info. That's how you get those degrees values that actually tell you that timing is off.

Regarding setting the timing, let's try one more time. I'm getting you tried crankshaft at TDC and camshaft locked with the tool. That's definitely not gonna work because that way camshaft is 90⁰ forward. You can set it old scool having the crankshaft on TDC with the flywheel mark on 0⁰ AND aligning the camshaft with the cam pulley mark in line with the HG mark. This is how they look aligned on mine. I yellow circled the marks on yours in the photo in post #50 above. As they are they look totally 90⁰ apart so having them in line I say you have the exact camshaft position corresponding to crankshaft TDC. Bang on, without any leeway as @GrandePunto PL showed you can have using the tools.

Attachments

Last edited:

Similar threads

- Replies

- 15

- Views

- 676