Introduction

Here is the latest addition:

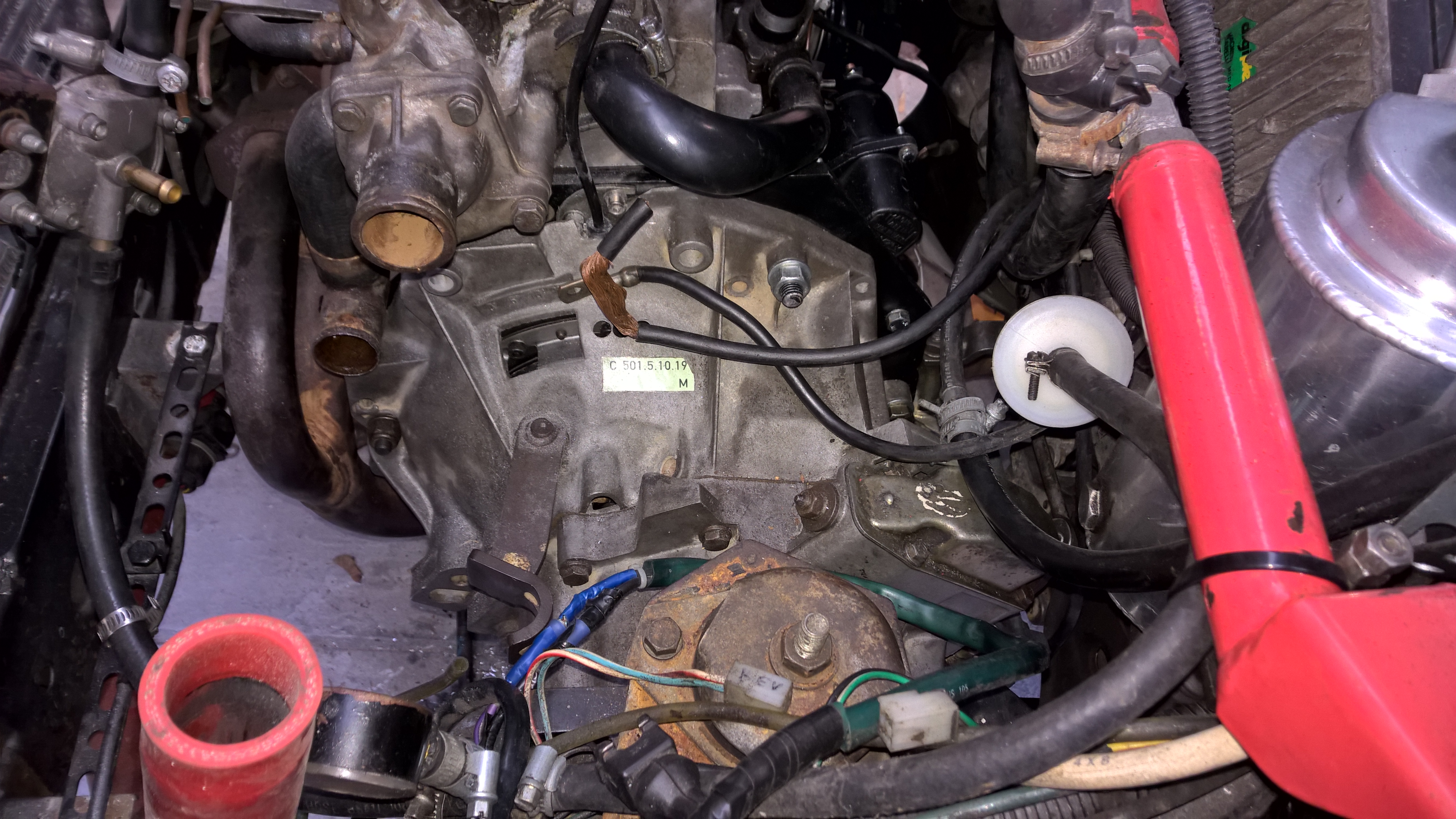

Ok, going to be a bulk update as have been madly obsessed in getting this fixed up after some gearbox issues

With the addition of the prop shaft I am not able to route the exhaust to the rear as the car is too low. So there was only one answer...side exit exhaust. I had the back box from the original Y10 Turbo which has a rediculous bore...but made for a funny image:

It wasn't practical though as it would have sat about 2" off the ground!...

So instead cut up and welded back together bits of the original exhaust with the adaptor for the cherry bomb exhaust :devil:

A nice neat routing now:

And fairly discreet position...looking forward to hearing it at full throttle with the window down :slayer:

Nothing sitting too low to the ground either and the 4x4 panda leaf springs are so much stiffer with all the weight taken out the back of the car...should be a completely different car in the corners...

Still awaiting the propshaft to be built and fitted but otherwise the car is now ready to get a fresh MOT...

So I mentioned gearbox issues...

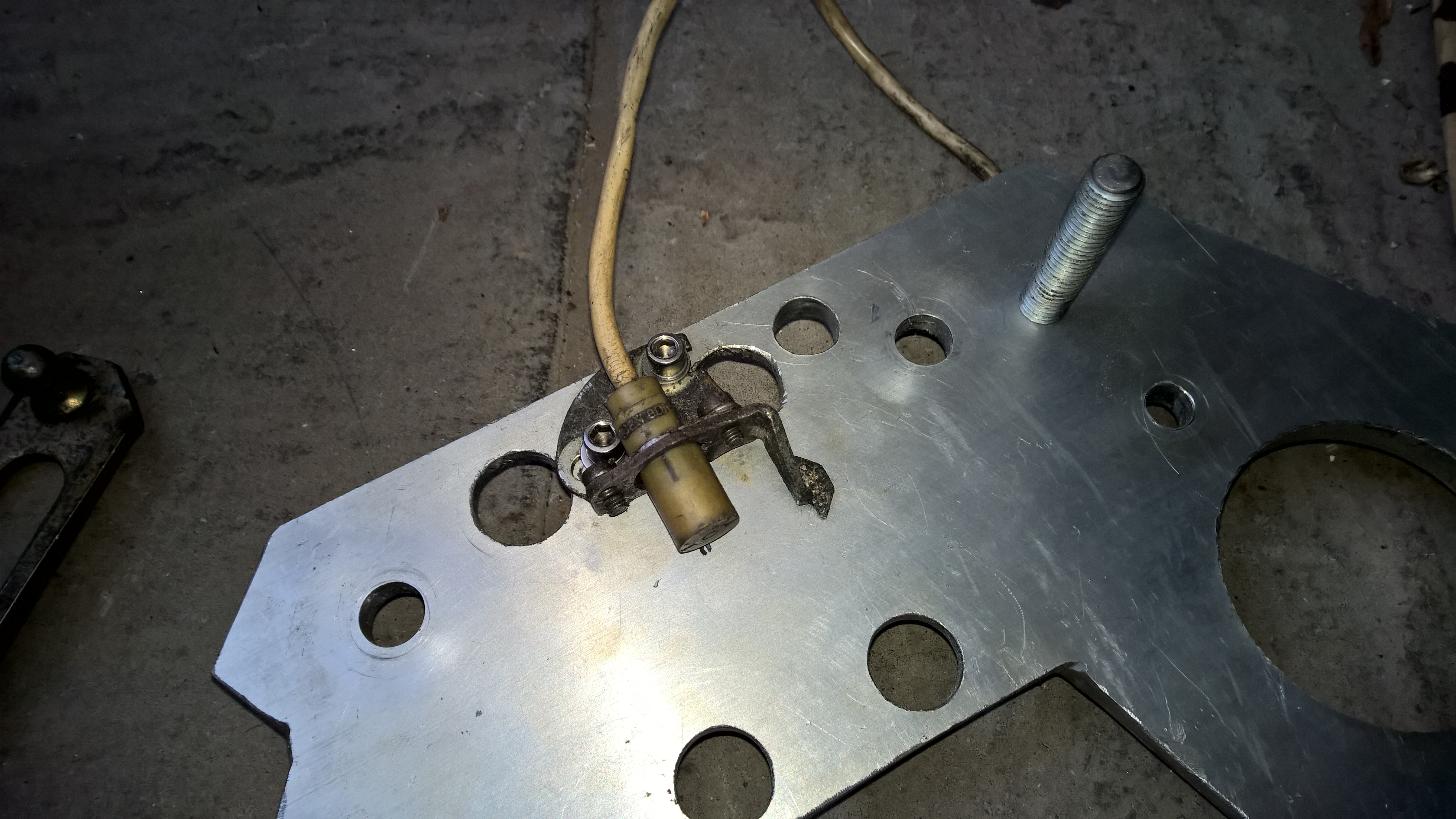

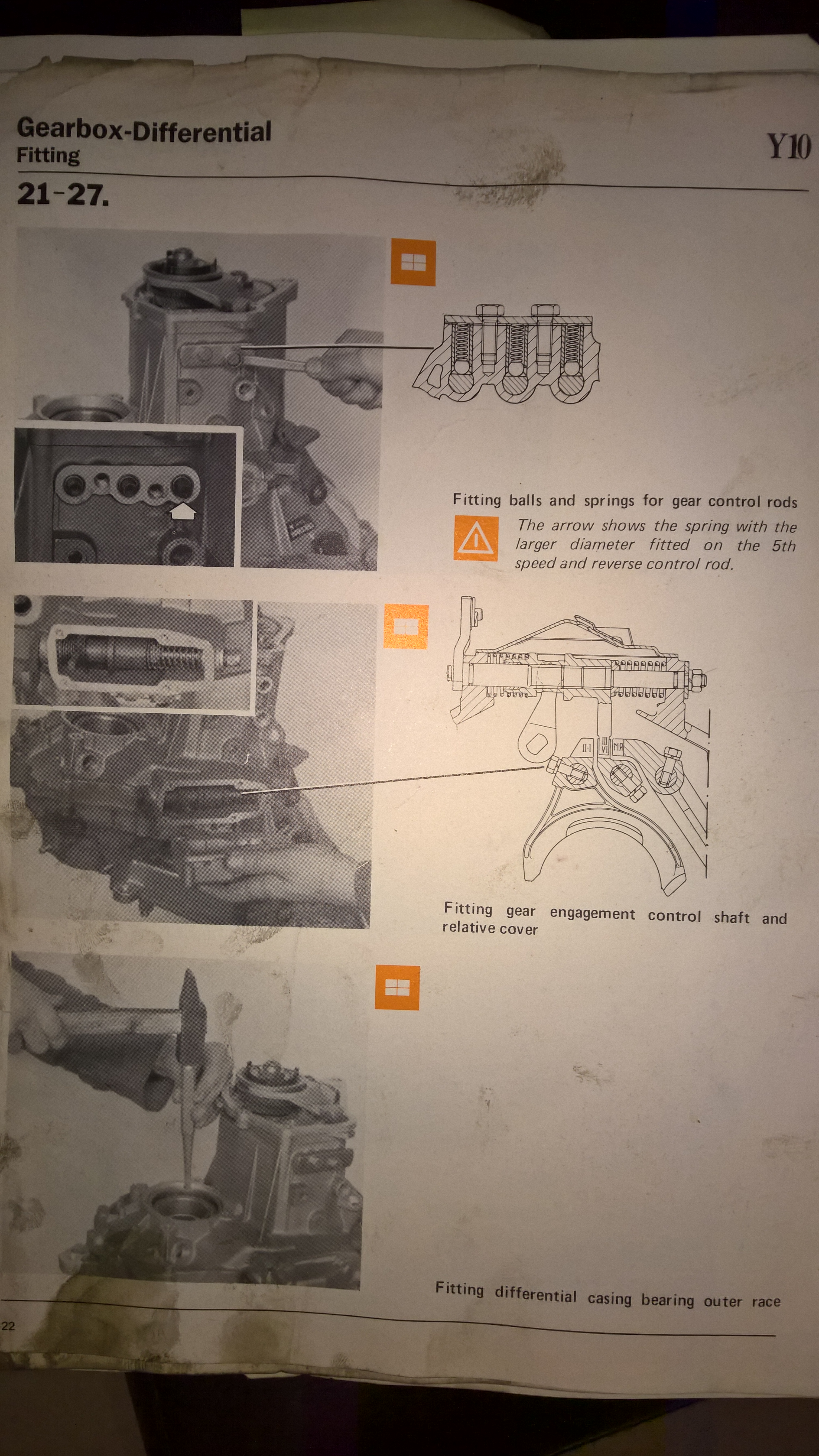

On the first attempt I found I got stuck into 5th gear and got locked out of 1,2,3 and 4th. Reverse gear grinded when attempting to engage but didn't go in thankfully. Anyway, I took the gearbox back out to have a look and found very little wrong. I did have these little springs in the wrong order...

...but on re-fitting the gearbox the same problem happened again so it wasn't that. Then it occured to me we have a gearbox guru amongst us :worship:

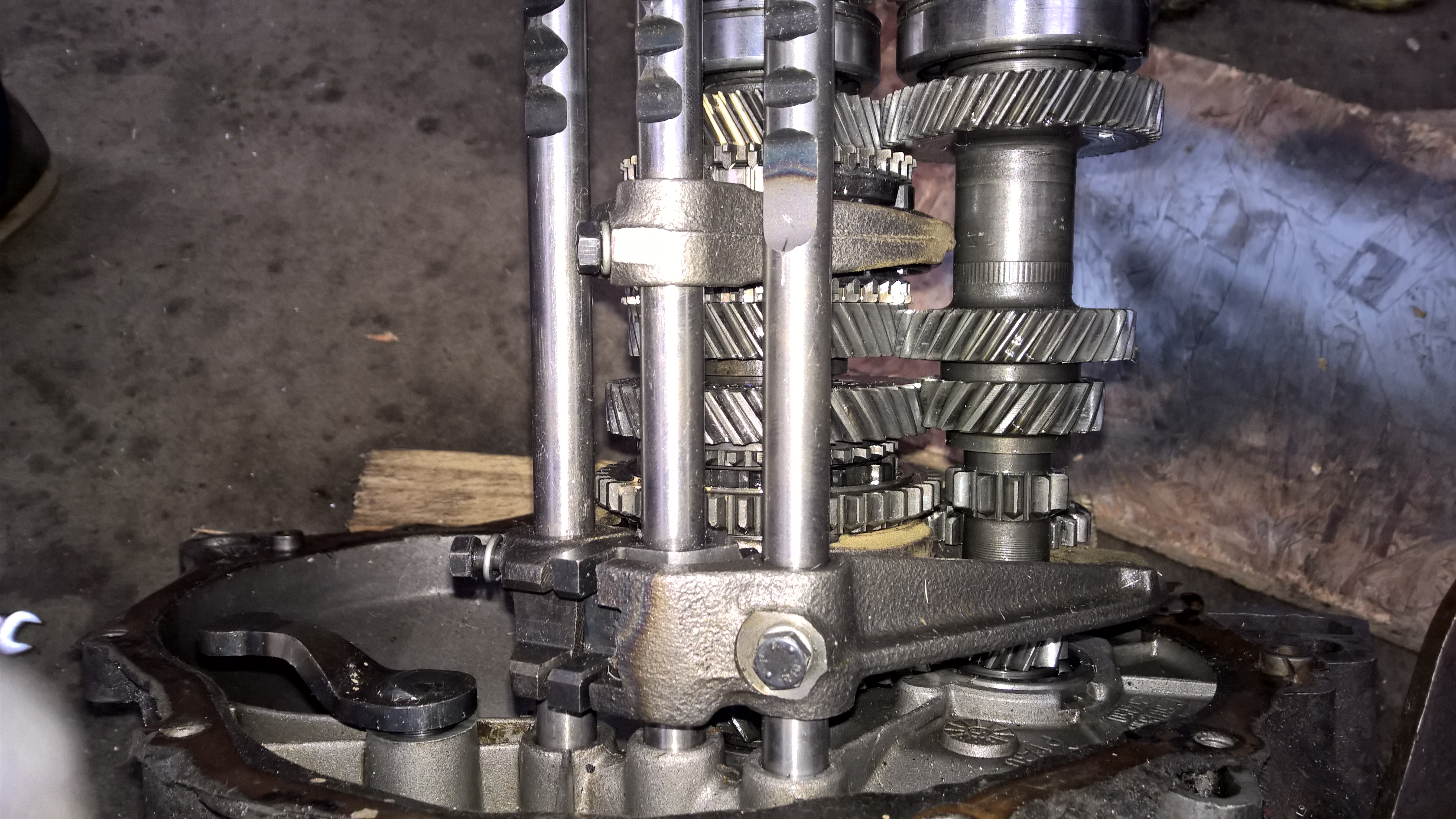

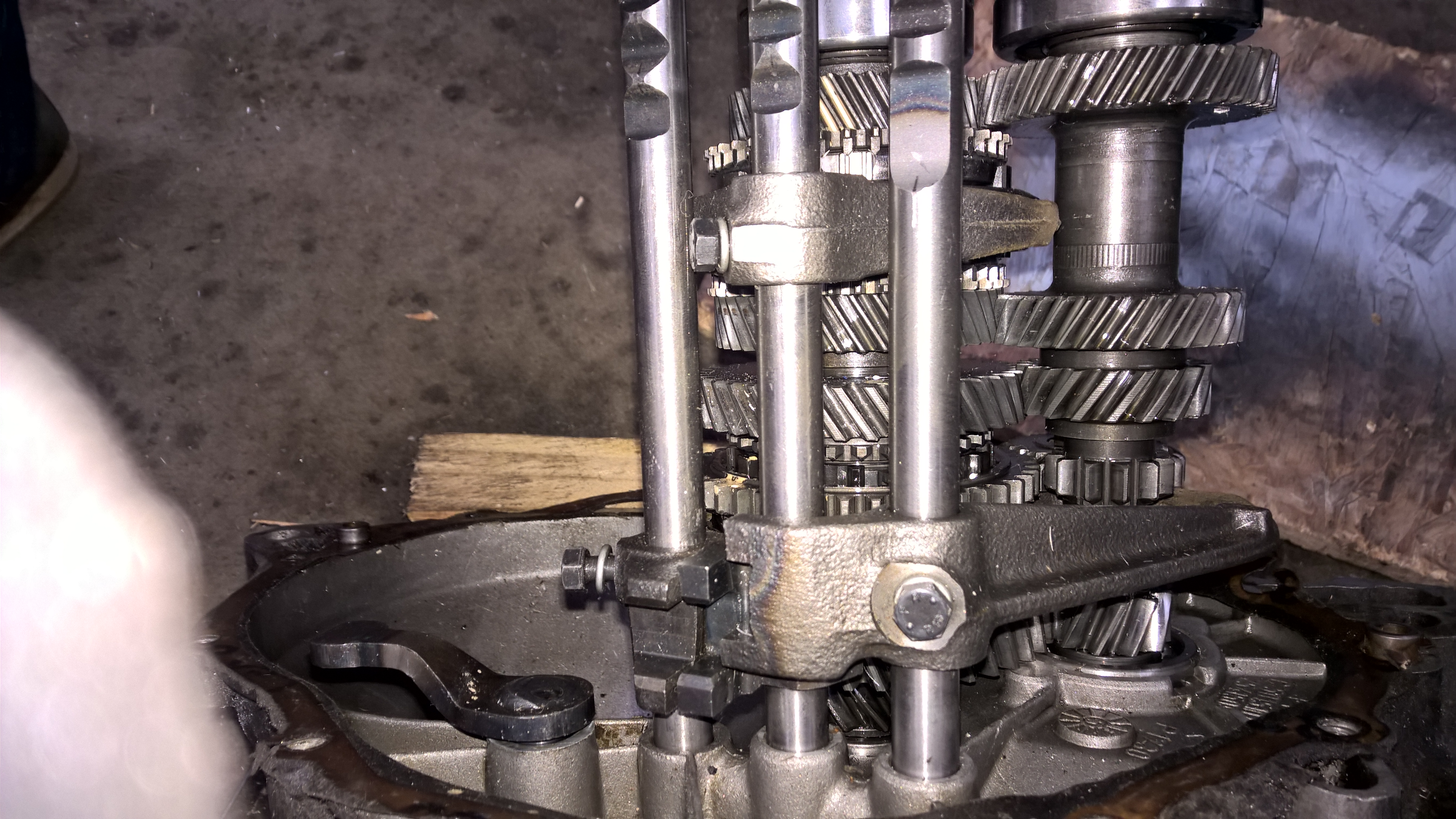

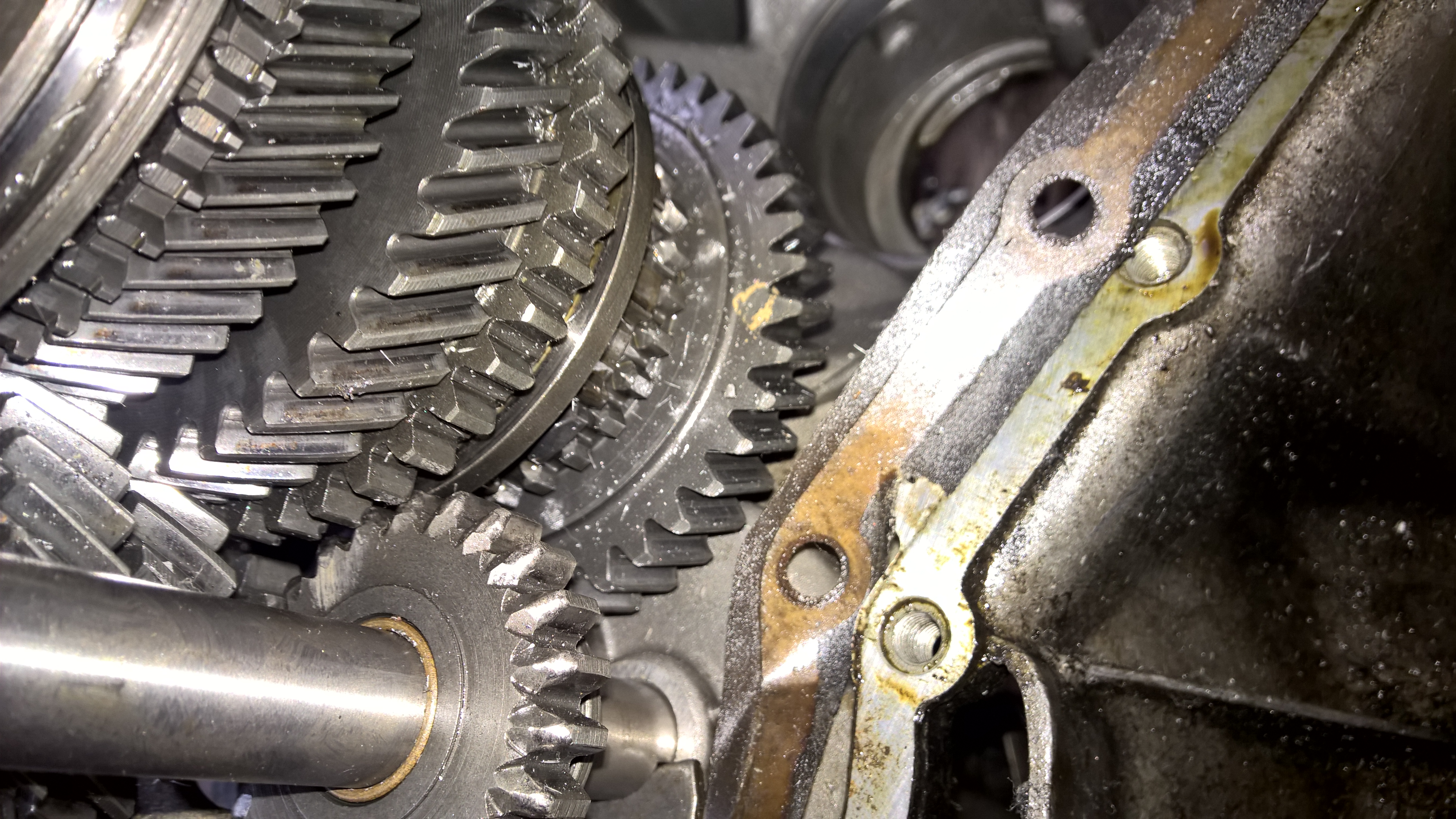

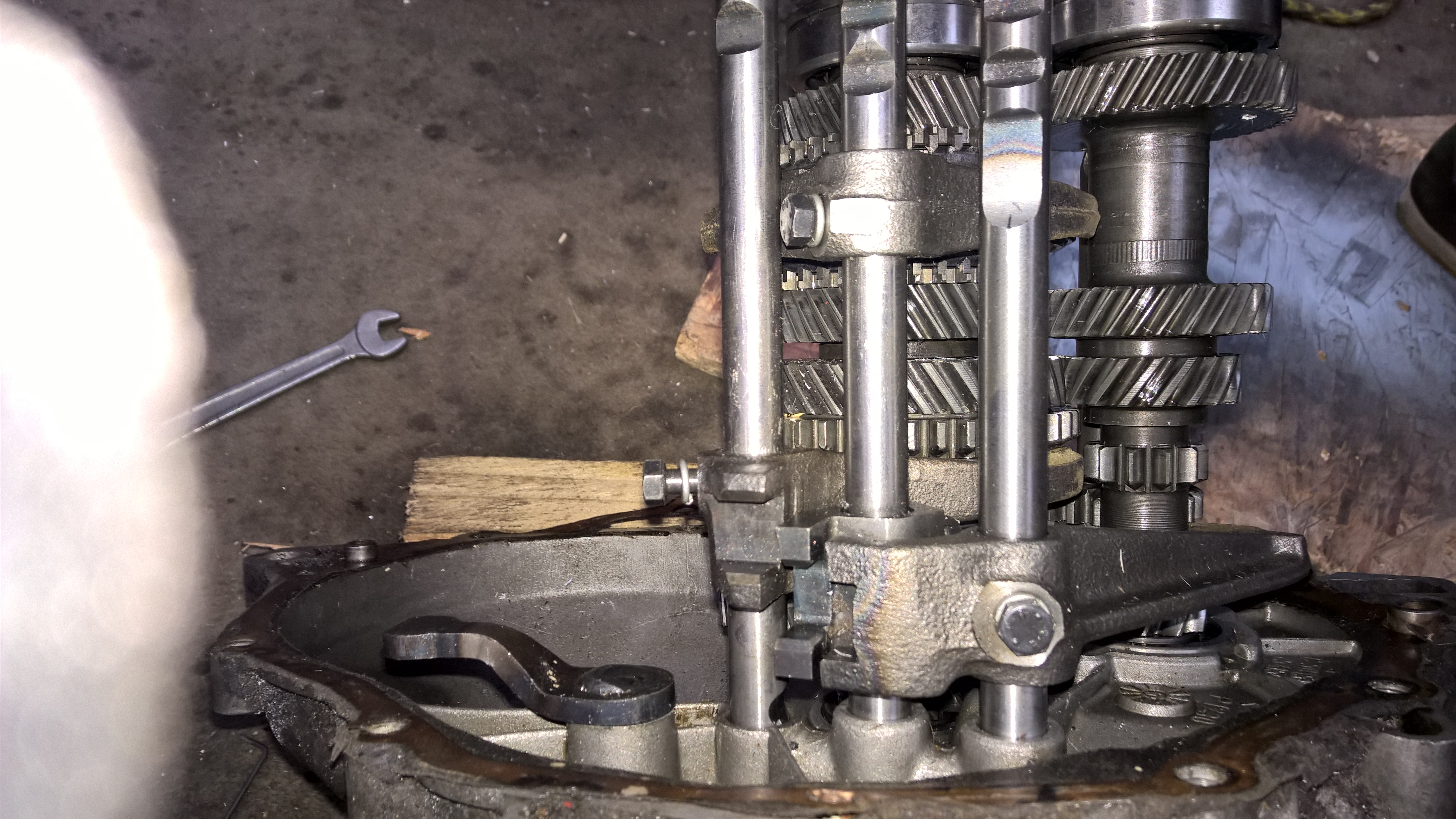

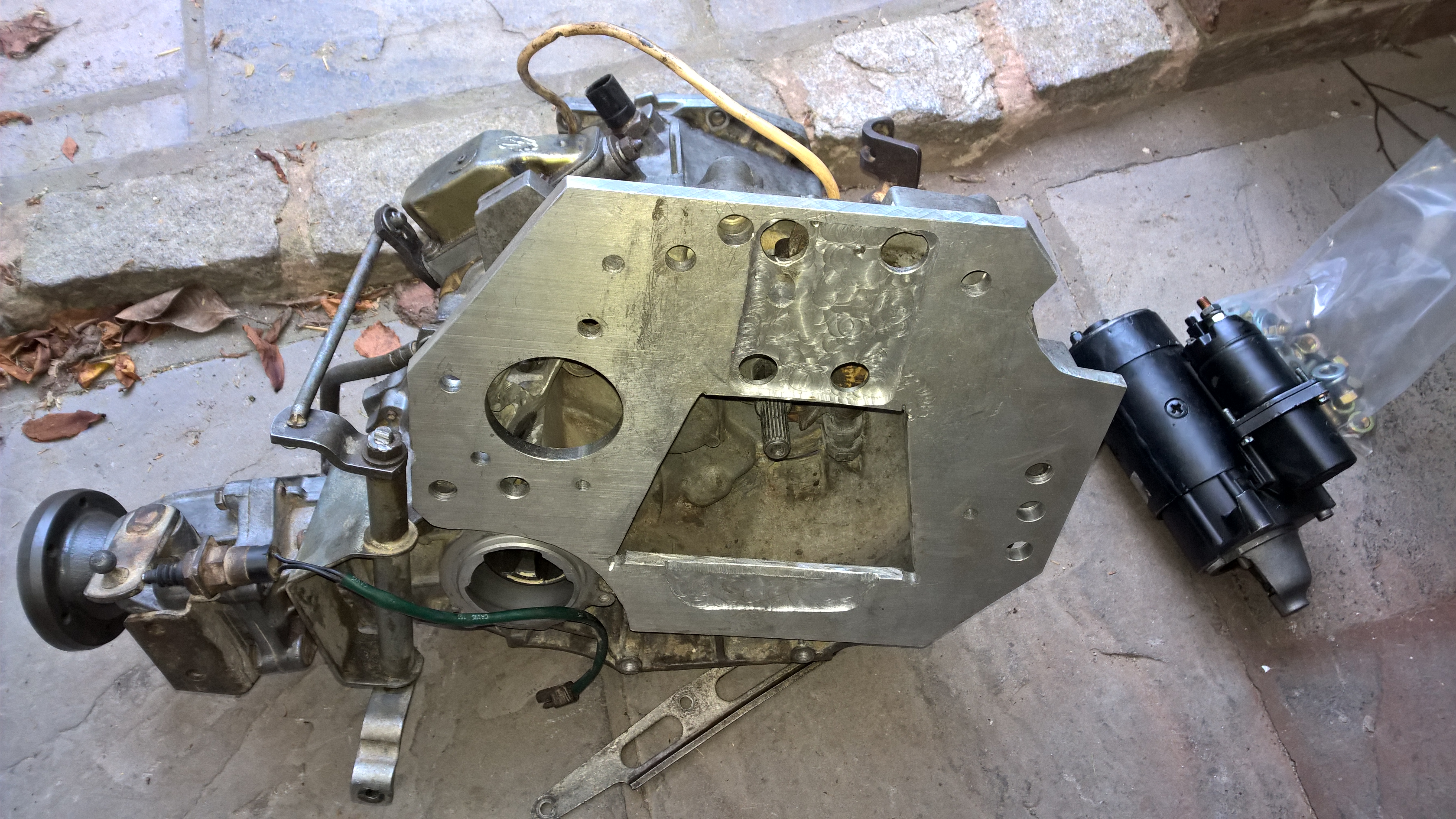

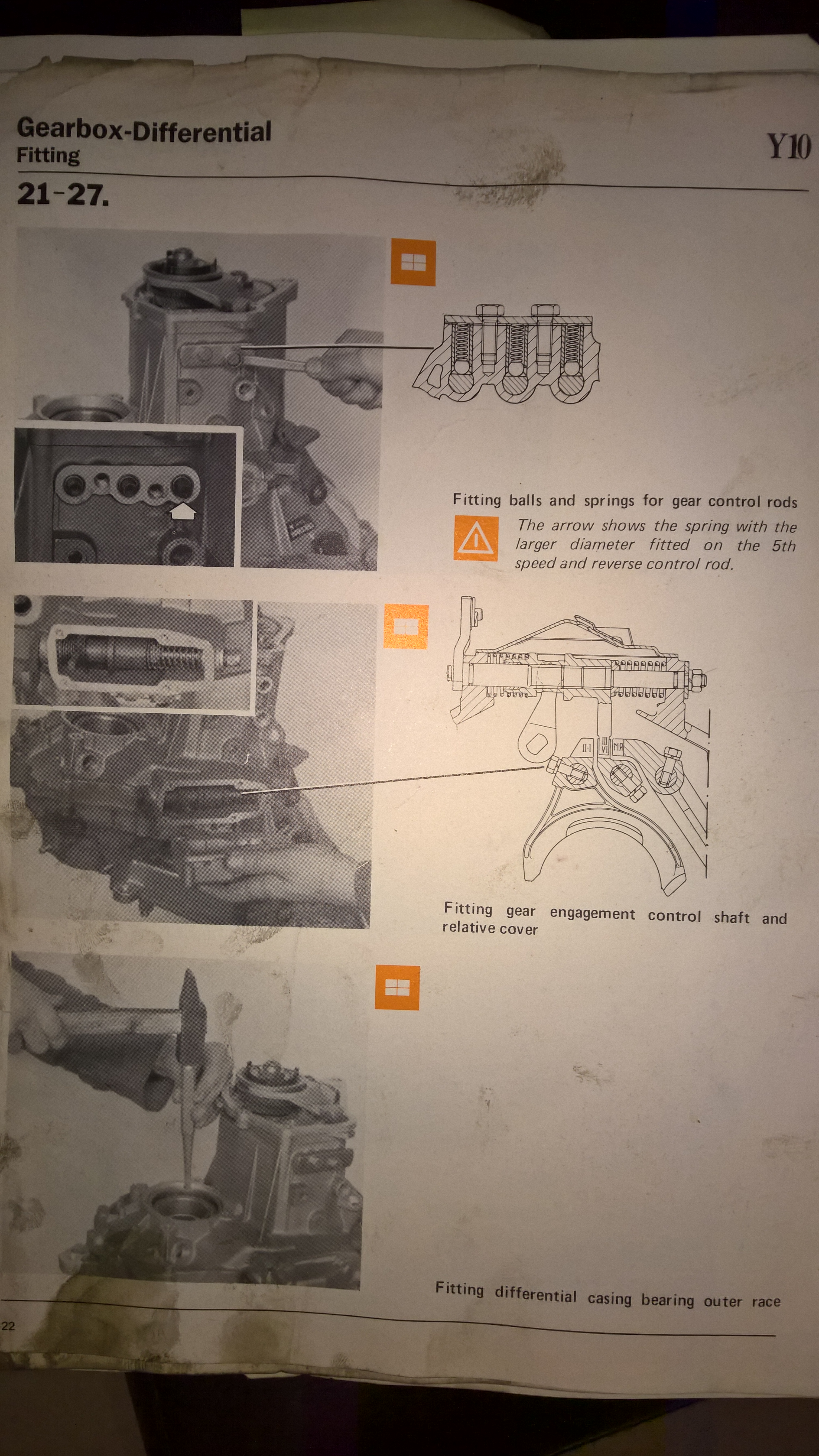

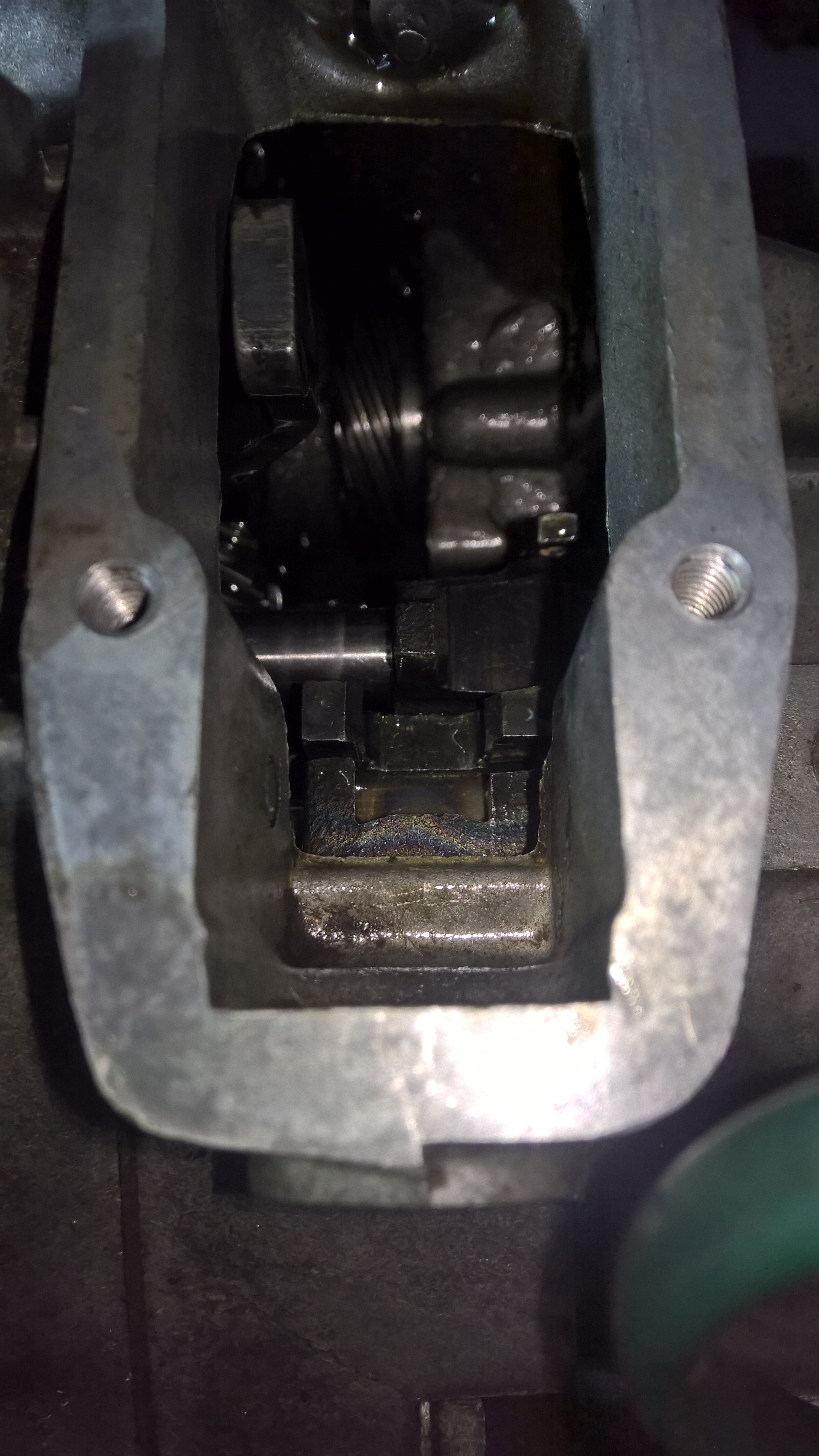

So post phone call with andyholli I had a strong idea of the issue. The top selector is splinned and can be fitted on in 2 positions! Only 1 is correct...the clue is the lever at the back (see image below) should not be vertical but at an angle when left in neutral like so...

So with this sorted the car drove around in all gears! So again huge thanks Andy H for helping me get to the bottom of it. And after a 5-10 minute phone call as well! Legend.

Here is a preview video of the cars first venture outside with the new exhaust and rear axle fitted:

https://youtu.be/zS_gMANOiuM

:slayer::devil:

:worship:

Mad awesome mate. Sooo glad you got to the bottom of the gear box issue. Can't wait to see this one in the flesh! You must give me a ride some time!

Wow, this is a nice thread. You've done some awesome work on this car!

Excellent work as usual Si! Hope the propshaft all works out ok.

The gearbox issue sounds like an easily done thing, I'm glad you've got it sorted, its something I'll have to remember when I get round to attempting a build of a high ratio 4x4 box.

I love how all of the bits of Hadrian will have gone from being thrashed up rocky tracks to being thrashed round a race circuit:slayer:

Still thinking alignment - if one more spline around on the 'lefty, righty' stick then 2nd (and 4th) won't be thrown so far into, or would be pulled further back out of, engagement to allow the detente springs to do their stuff..?

Everything else is positively built - shafts have no option but to be in one position relative to their input selectors due to cut outs for pinch bolts so it can't be an issue deep inside the box..

He says, keeping the humble pie slice close to hand.

Have another go Si, you're nearly there.