Introduction

Here is the latest addition:

I went the yellow bulb route when I decided I needed yellow lights

They looked cool when lit (IMO) but awful in practise, it was like driving with a couple of candles in jam jars

I do think they look cool on Pandas and Marbellas alike of course...Yeah I actually got the desire from having a set of yellow bulbs I got from the donor Y10 turbo lights. Loved the look when lit, and these weren't too dull either but they blew and I couldn't find the same ones again. Not sure how good this will be at night, but the Marbella headlight design is much better for lighting up the road anyway. Will try to give it a test drive soon and a video as well...

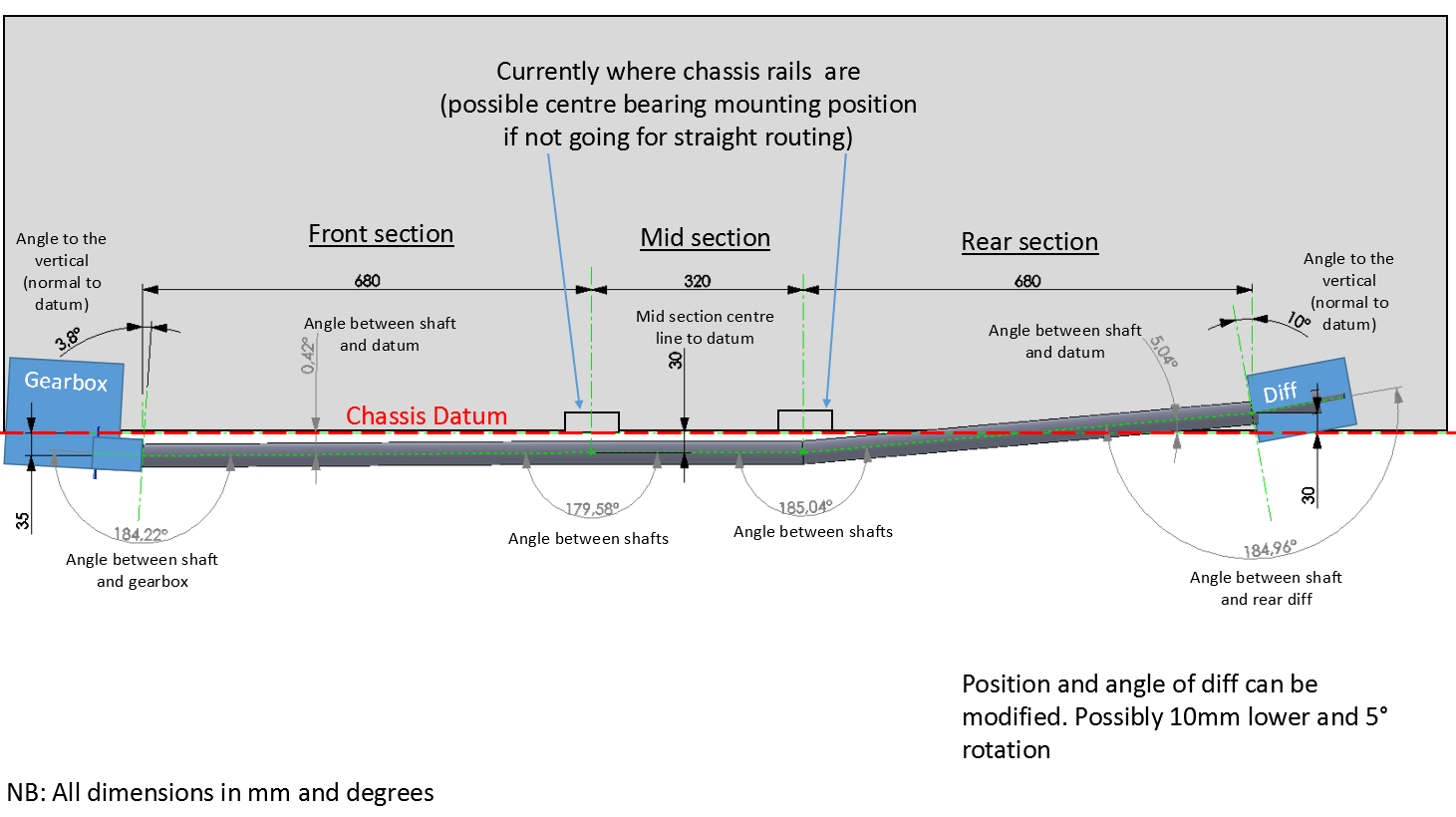

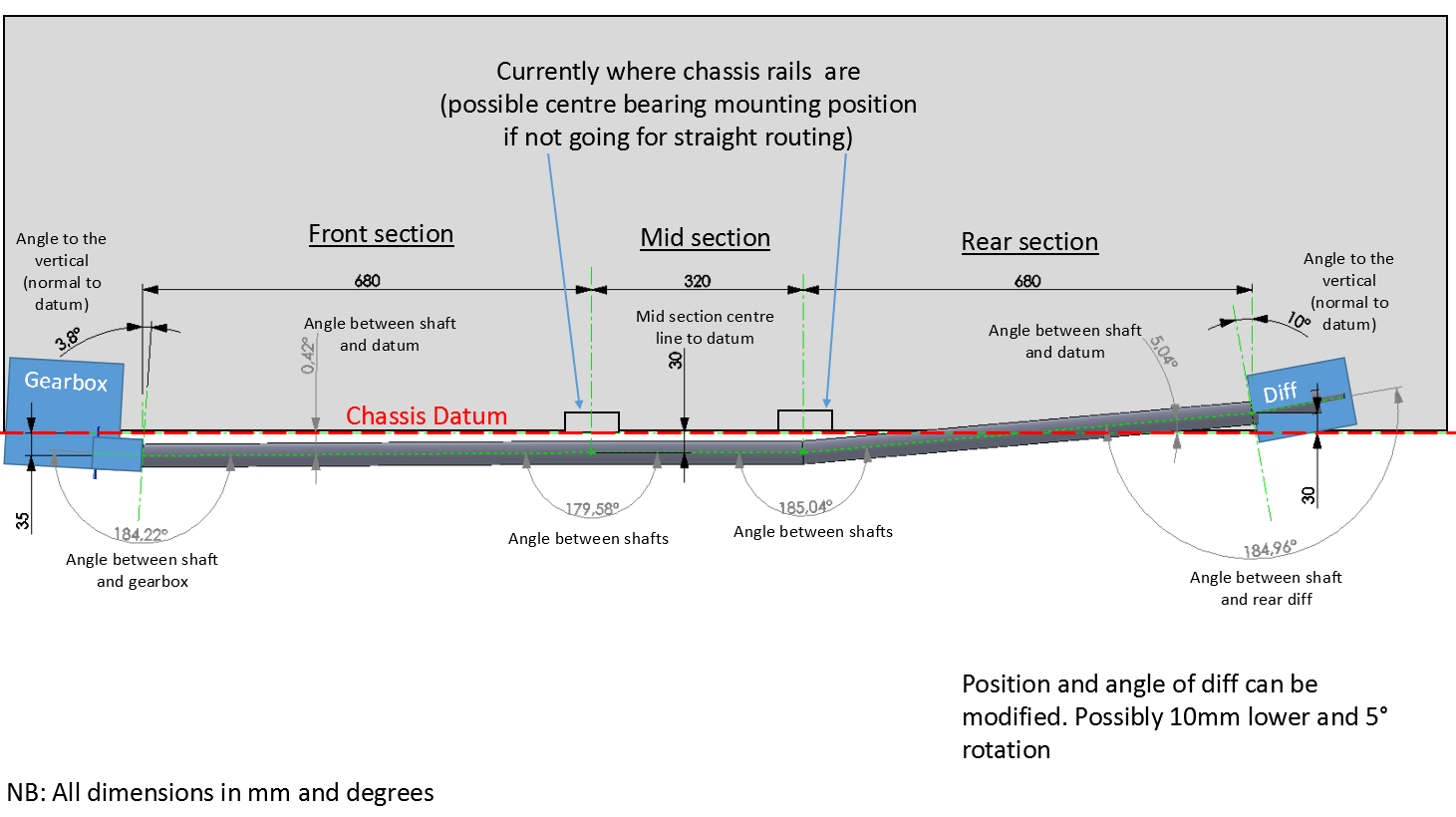

Great progress (I'm sure I can smell the beginning of the finish line) but can you explain the physics of this problem to me - I thought a joint was a joint, why do these minor angles matter so much please?

It's not keeping me awake but it is bothering me that I don't understand at all, absolutely not a clue..

Cheers Si.

put my feet up and not think about it again.

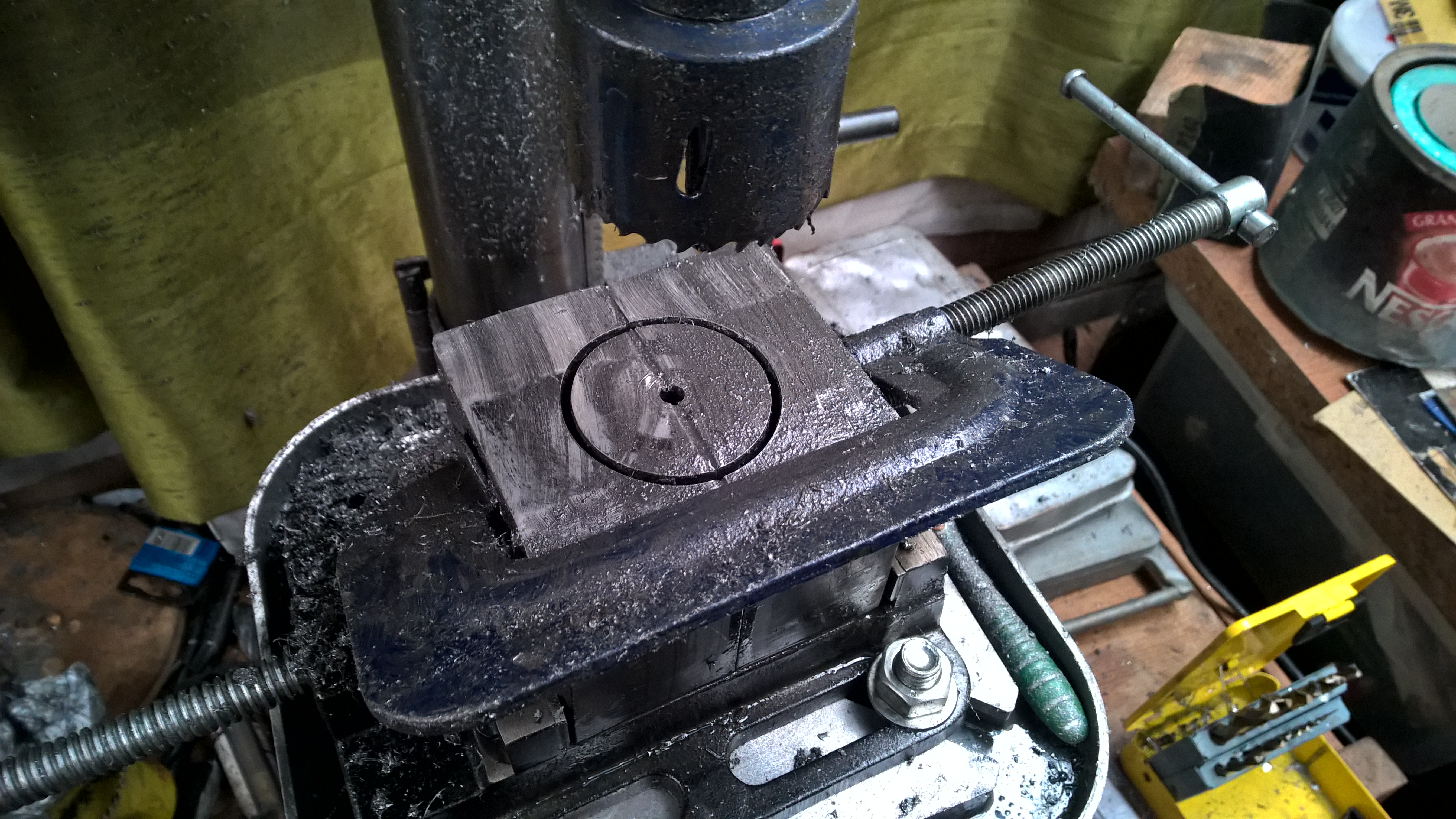

Got a bit more engineery...

Think will have to reduce the amount of lowering on the rear to achieve a straighter routing but it isn't looking like crazy angles now

Lovely work, I salute you Sir.

Must ask though - the damper body looks as though it could stress against the bracket it shoulders up to, under droop perhaps. Does the spring angle the axle 'backwards' as it travels down?

I know there loads to do still but what threaded rod did u use 8.8 or greater is that will be fine. No discs at rear yet ? Ah no it's only for going fast up hill not stoping !!! Ha ha