Introduction

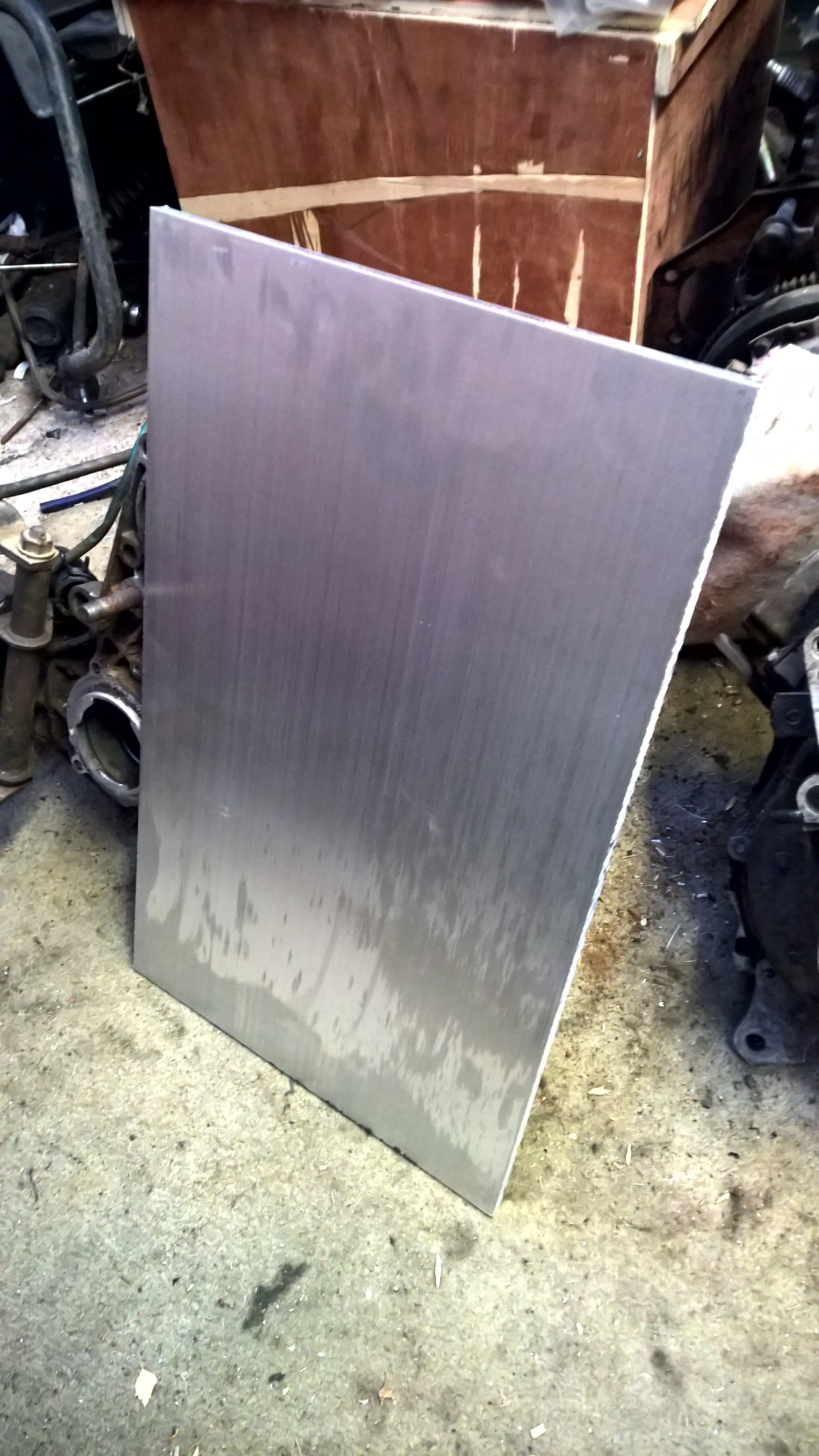

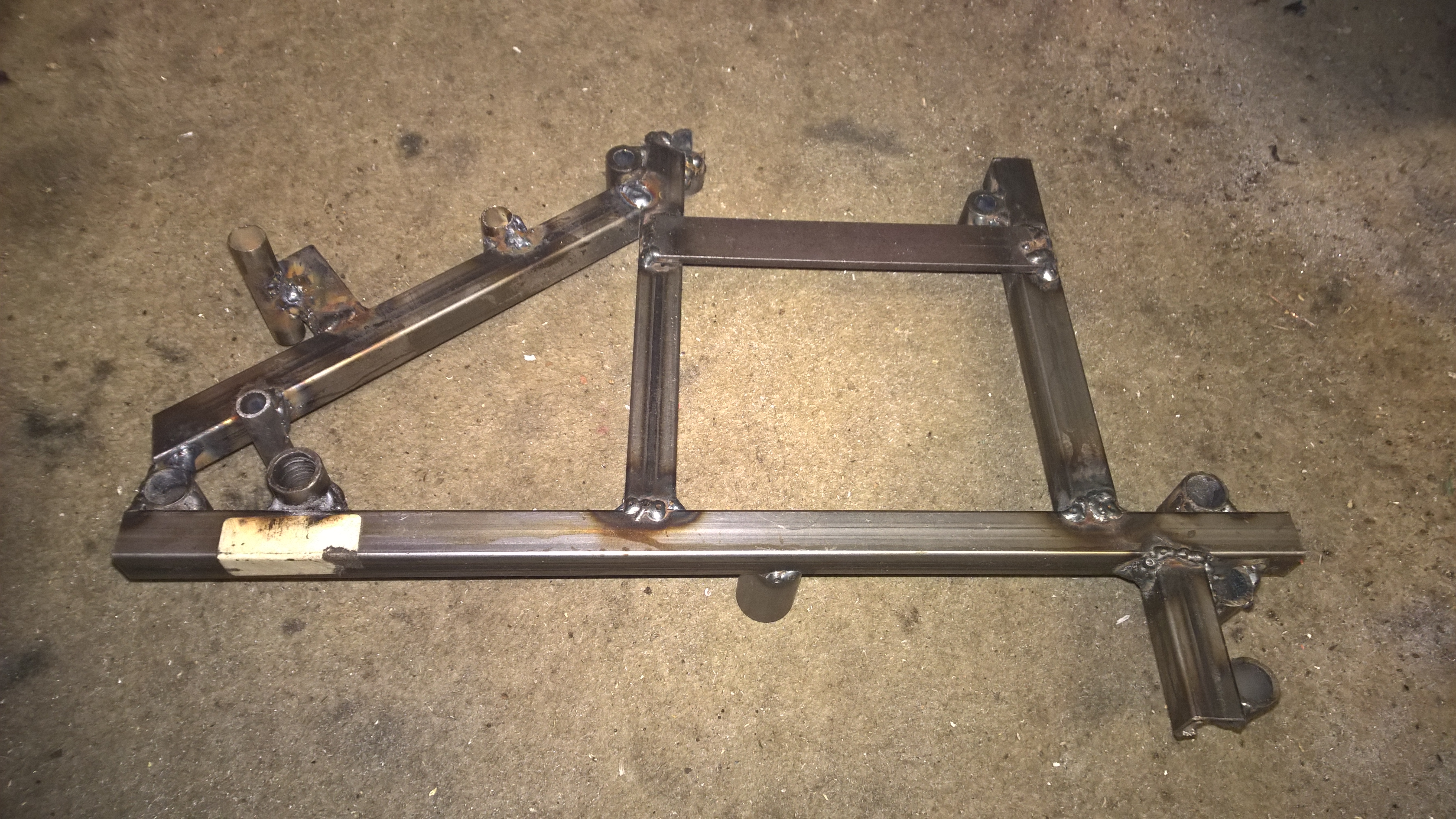

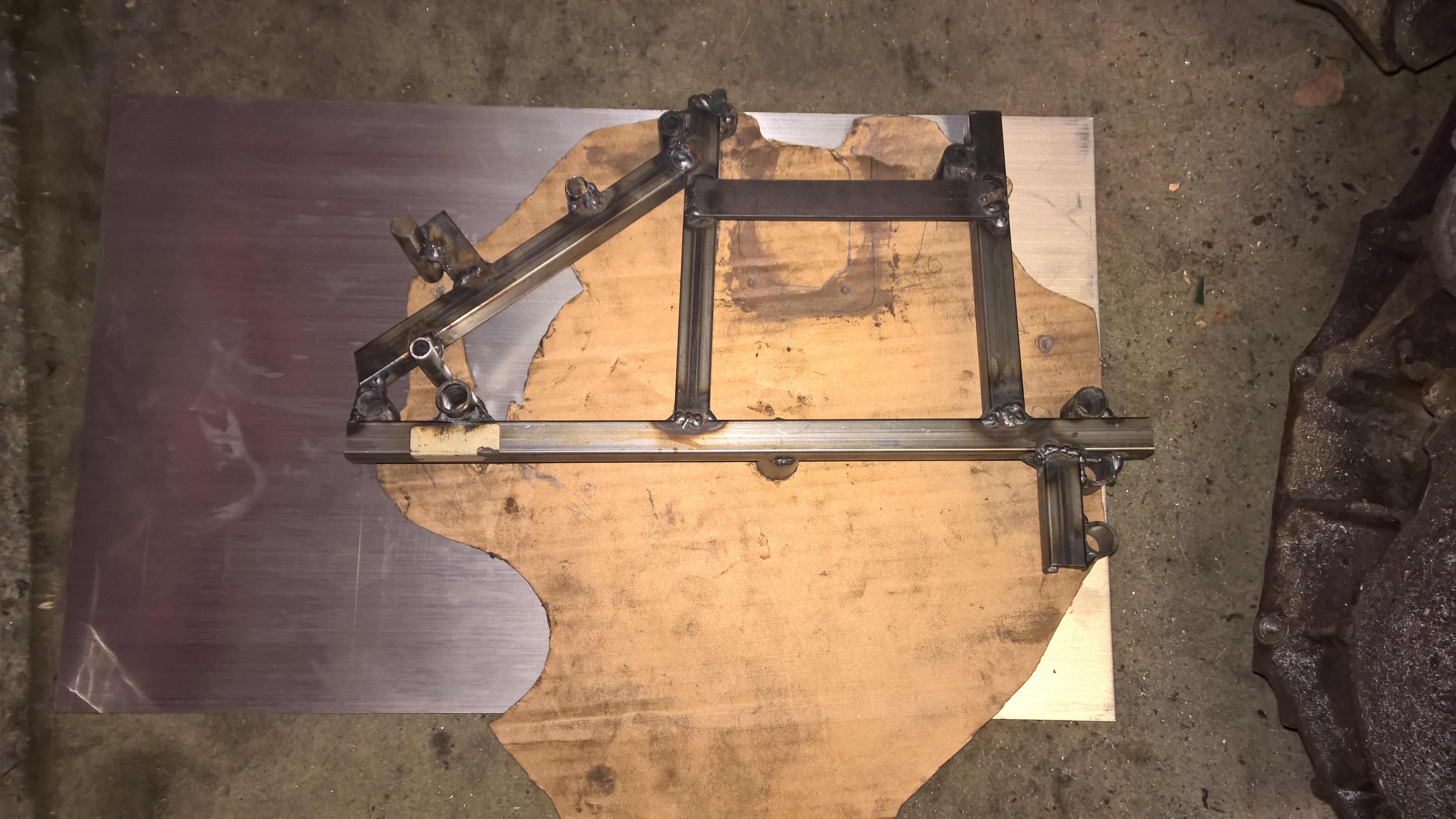

Here is the latest addition:

Quick guide to aluminium/ alloy grades

https://www.metalsupermarkets.com/7-things-consider-choosing-aluminum-grade/

I would stick with at least average corrosion resistance. Strength depend on space available, if less than 10mm go for aerospace/ aviation grade.

I think its a bit of a silly idea trying to make it rwd really but cool idea nonetheless, prob be the twitchiest car ever in reality though lol.

I am actually having a future plan making a Marbella (my 'Bella) with Panda 4x4 drivetrain minus the front driveshafts.

And some changes in the engine bay, and than go forward with the doorknobs(/go sideways).:slayer:

AND partly reasons for the RWD Marbella idea are cutting off problems like front driveshaft sealing leaks , grease or tranny oil loss, clicking/cracking/bad 'shafts, and the rarity and fun factor.

Its epic already!

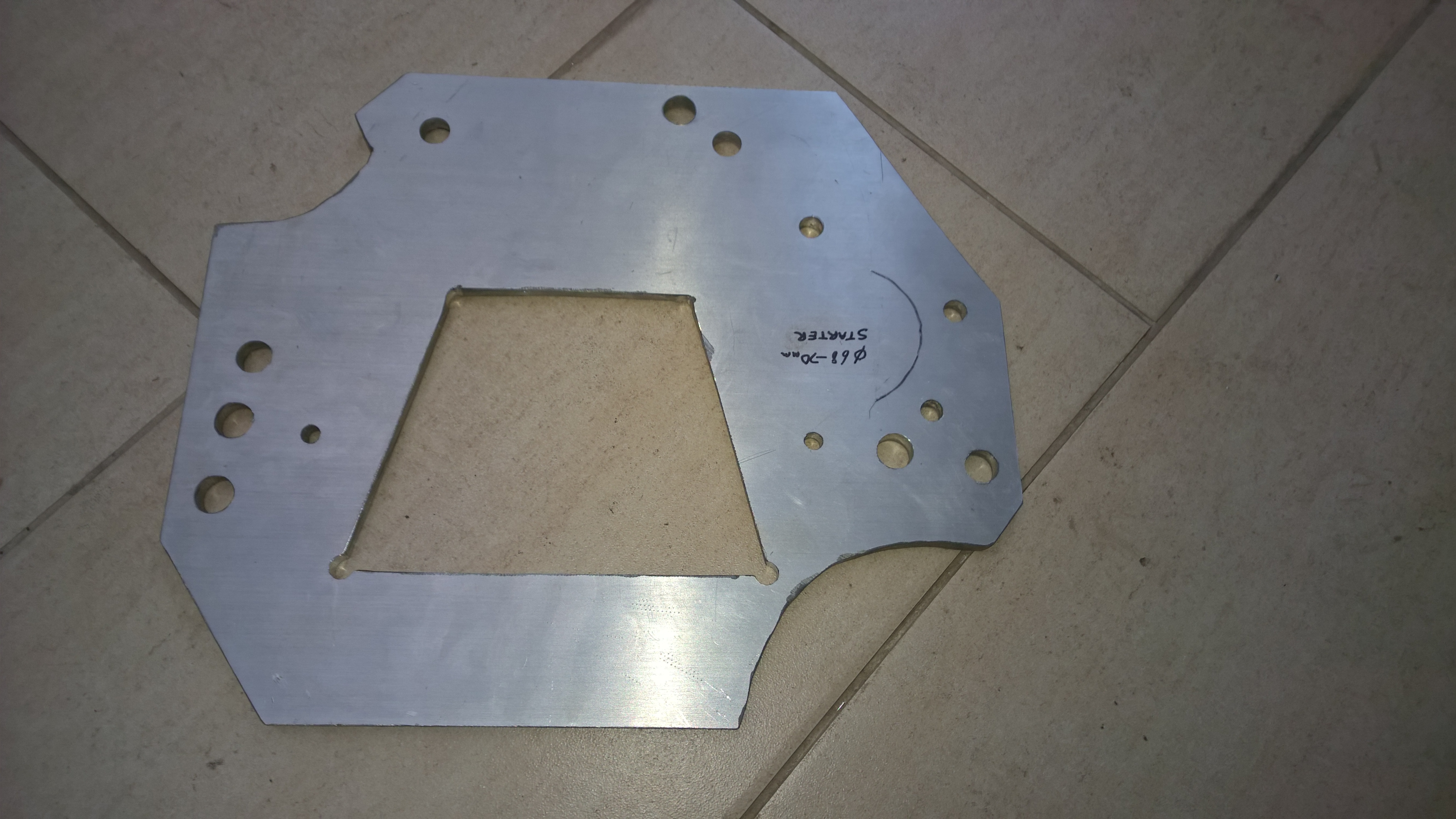

Mk 1 4x4 bellhousing has opening for starter motor in front of the engine doesn't it Si? - Would that help ease the cutting up?

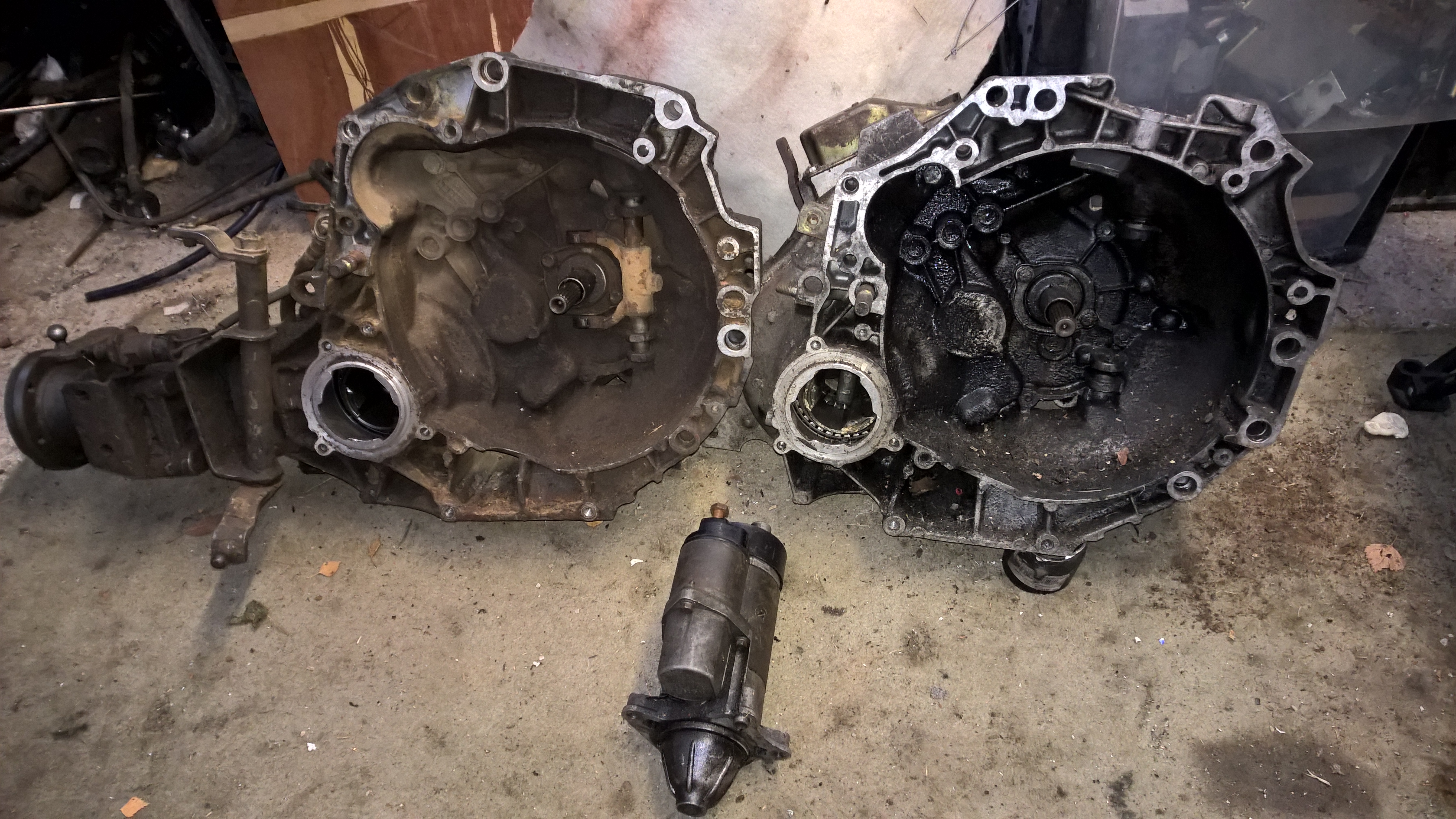

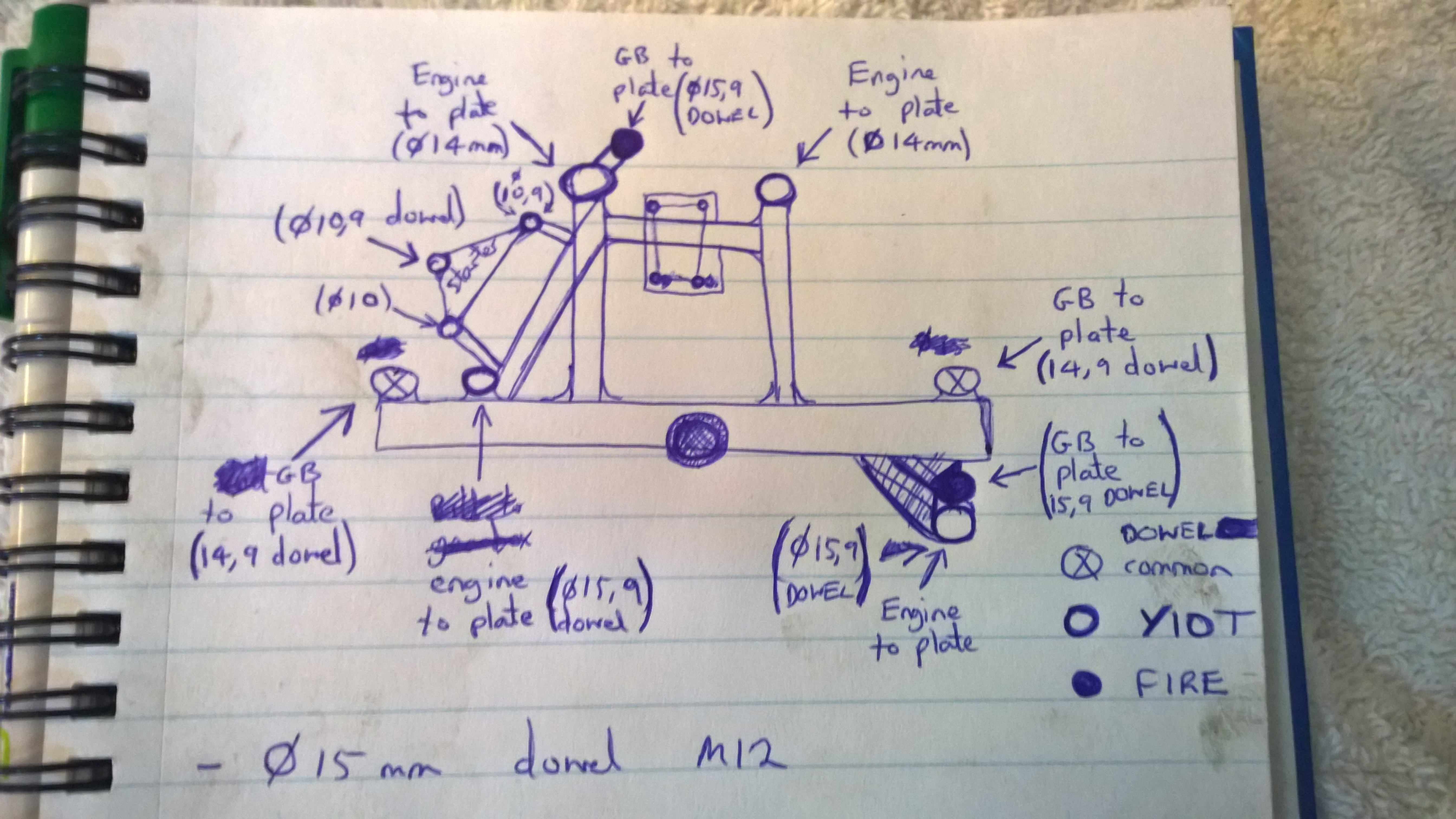

So here are the differences between FIRE bolt pattern and Y10 pattern (left FIRE 4x4, right Y10 turbo 2wd):

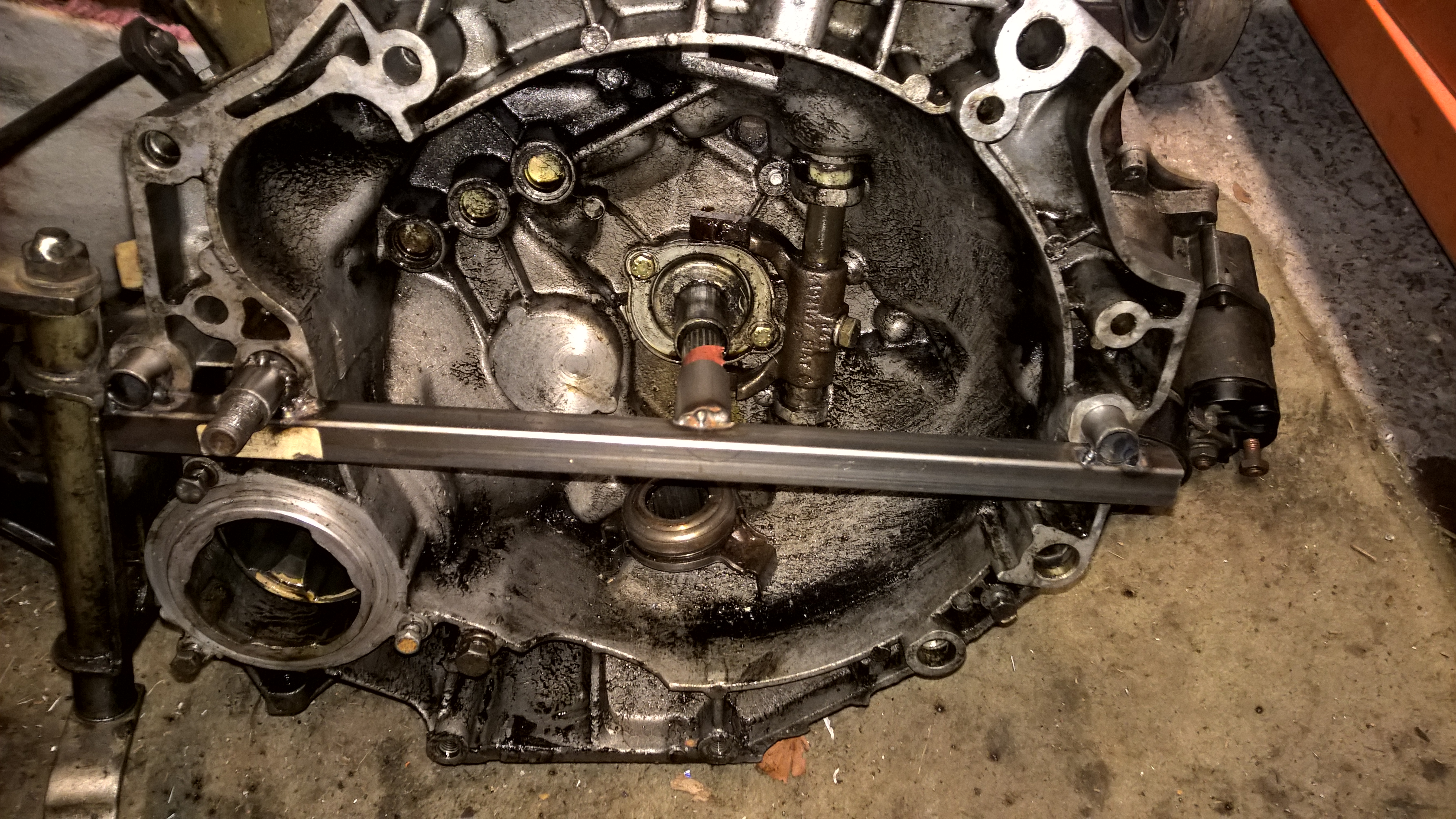

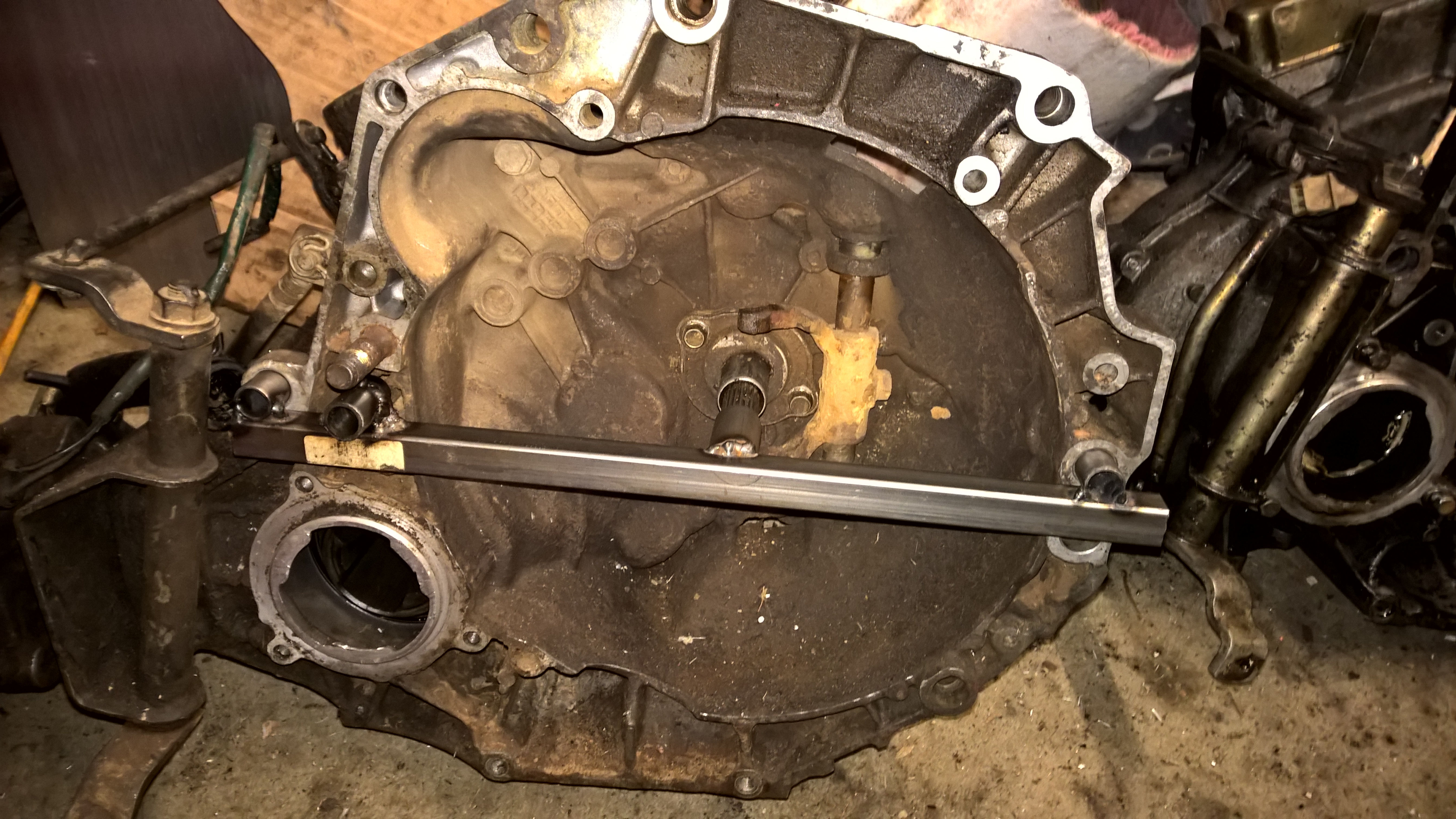

One confusing thing...the bottom edge of the bell housing I think should be horizontal with the car. The top edge is normally also horizontal on both my mk1 and the Y10 turbo. Can anyone confirm that the top of the bell housing is not horizontal but is sloped on their FIRE Pandas?

I will need to check the prop shaft exit angle is right anyway, but thought I should check if I'm thinking right...

Checked my Y10 Fire and the top of the bellhousing is not horizontal to the car. It slopes gently with the bulkhead end higher.

(maybe I need to get one of these new fandangled post '86 FIRE Pandas that are out now....for comparisons at least :devil

- Just more to go wrong, do it!.:yum:

Excellent shed engineering going on here Si! I have one question and that is how are you going to deal with the fact the input shaft is 10mm further away from the flywheel than it should be?

Epic work Si! You are an engineering legend!