You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Rear Shock absorbers

- Thread starter MLW

- Start date

Currently reading:

Technical

Rear Shock absorbers

Yep

Just top bottom bolt

Needs to be tightened up at correct ride hight

Standard shocks are fine

Just top bottom bolt

Needs to be tightened up at correct ride hight

Standard shocks are fine

What are standard shocks?Yep

Just top bottom bolt

Needs to be tightened up at correct ride hight

Standard shocks are fine

Fiat use at least 2 different manufactures

Cofap and Monroe

Makes no difference

Rubber bushes normally go first

Cofap and Monroe

Makes no difference

Rubber bushes normally go first

Last edited:

I take it’s on 155 tyres

The tall sidewalks will make it appear a bit wobbly.

There not much to be gained from the rear shocks unless those fitted are worn out

In my opinion the best tyre from the passenger seat anyhow especially over bad roads and speed humps

The tall sidewalks will make it appear a bit wobbly.

There not much to be gained from the rear shocks unless those fitted are worn out

In my opinion the best tyre from the passenger seat anyhow especially over bad roads and speed humps

Usually good for 50000 miles if fitted properly and the rear is normally lightly loaded

We have seen some fitted by a garage rip the rubber bush’s out in about a year

We have seen some fitted by a garage rip the rubber bush’s out in about a year

I take it’s on 155 tyres

The tall sidewalks will make it appear a bit wobbly.

There not much to be gained from the rear shocks unless those fitted are worn out

In my opinion the best tyre from the passenger seat anyhow especially over bad roads and speed humps

When I did mine ..and wrote the GUIDE

I cleared put and painted the spring pans too

I cleared put and painted the spring pans too

YesAmazingly Halfords had SACHS for £32.30 each. Numbers match up with the SACHS website. Does the car need to be down on the springs for final tightening?

Important

- Joined

- Sep 14, 2009

- Messages

- 19,975

- Points

- 3,977

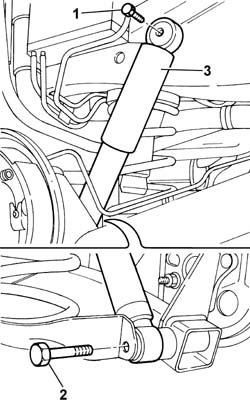

The top mounting bolt is very easy to cross-thread and the self cutting tip makes thead damage a considerable problem. Fit the top bolts first. Tighten fully then slacken 1/2 turn so the shock sleeve is loose. Fit the bottom bolts. Jack up the swing arm until the car body just starts to lift off the axle stands. Fully tighten both bolts. Repeat for the other side.

aha…now thats interesting. upper and lower bolts final torque up (70nm) wheels on ground?Yep

Just top bottom bolt

Needs to be tightened up at correct ride hight

Standard shocks are fine

ahhh, I'm not so convinced on this. I can understand the suspension arm bush being in a horizontal position and having a big diameter so being on the floor thing. The smaller rubber top and bottom bush on the rear shocks are in a verticle position with a lot more travel tolerance, I would like to see some maths on this.aha…now thats interesting. upper and lower bolts final torque up (70nm) wheels on ground?

Knock yourself out if you want to do the maths

I'd just go with what the fiat instructions say

If it wasn't important they wouldn't have bothered, time is money as they say

Someone had the shocks changed on a lift and they failed at the next MOT

Note that this operation is essential to ensure efficient rear suspension operation and to prevent premature damage to the shock absorber and rear axle rubber bushes

I'd just go with what the fiat instructions say

If it wasn't important they wouldn't have bothered, time is money as they say

Someone had the shocks changed on a lift and they failed at the next MOT

Note that this operation is essential to ensure efficient rear suspension operation and to prevent premature damage to the shock absorber and rear axle rubber bushes

Note the. Upper bolt is a different torqueaha…now thats interesting. upper and lower bolts final torque up (70nm) wheels on ground?

ahhh, I'm not so convinced on this. I can understand the suspension arm bush being in a horizontal position and having a big diameter so being on the floor thing. The smaller rubber top and bottom bush on the rear shocks are in a verticle position with a lot more travel tolerance, I would like to see some maths on this.

You can see the change in angle of the shock as the spring pan arcs up

Still need a little more time with the excel spreadsheet, but the official fiat instruction was always going to be the top trump.

Would like to see the torque wrench used on that top nut when the car is on the deck to get 80Nm, I could only just manage an offset ring spanner.

Hey it is in the FIAT instruction so must be doable.

Would like to see the torque wrench used on that top nut when the car is on the deck to get 80Nm, I could only just manage an offset ring spanner.

Hey it is in the FIAT instruction so must be doable.

Measure from the centre of the hub to the top of the wheel arch

Take the wheel off

Jack under a strong part of the axle and lift it up until centre of the hub to the top of the wheel arch is the same measurement

Torque up the bolts

Take the wheel off

Jack under a strong part of the axle and lift it up until centre of the hub to the top of the wheel arch is the same measurement

Torque up the bolts

Now hang on thats cheating!

Plus its not FIAT official.

A good bit of advice/tip for the future if mine fails the MOT next year.

I lowered the car but left enough gap in the arch to get a socket on it.

At the time I thought it was the lesser of two evils.

Correct torque but not fully loaded or fully loaded and guess a value in a cramped space with a short ring spanner

I still got the exhaust to do any issues its going to be posted on here first.

Plus its not FIAT official.

A good bit of advice/tip for the future if mine fails the MOT next year.

I lowered the car but left enough gap in the arch to get a socket on it.

At the time I thought it was the lesser of two evils.

Correct torque but not fully loaded or fully loaded and guess a value in a cramped space with a short ring spanner

I still got the exhaust to do any issues its going to be posted on here first.

Similar threads

- Replies

- 10

- Views

- 922