And buy some dielectric/silicon grease to slaister around inside the rubber boot before you push the connector back onto the plug. This cuts down on the possibility of shorts to earth but more than anything makes it easier to pull the connector off the plug next time you come to do it.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Fiat Panda 1.1 MK3 2010 Changing Spark Plugs

- Thread starter AlexJD

- Start date

Currently reading:

Technical Fiat Panda 1.1 MK3 2010 Changing Spark Plugs

I do just in case but honestly more worried of the boot snapping somehow and getting stuck.Have a set of new leads at hand..as there is ALWAYS a risk of damage

Tried several times today on the most exposed connector (furthest to the driver's side) but it won't go quietly.

You can pull it a tiny bit and very slightly turn it but no amount of patience, lubricant or swearing seems to get it to move any further than before. I was hoping a bit of repeated moving over the day would gradually coax it out but no good. Possibly fused?

Nowhere in the West Yorkshire area had any spark plug/hose pliers so I've ordered some different ones that should give me some more grip and leverage before I throw in the towel.

- Joined

- Sep 14, 2009

- Messages

- 19,924

- Points

- 3,959

Poke a hole through the plug cap with a small screwdriver, squirt in some WD40** and wiggle it around. When it does come out, fit a set of new leads with silicone grease.

The straw is probably too short, but you can get longer ones on eBay.

The straw is probably too short, but you can get longer ones on eBay.

I like this idea. I'm thinking that if you used a fine hypodermic filled with liquid silicone, you might even be able to reuse the leads.Poke a hole through the plug cap with a small screwdriver, squirt in some WD40

- Joined

- Sep 14, 2009

- Messages

- 19,924

- Points

- 3,959

If you have the syringe and lubricant why not. IMO, for what they cost might as well replace the leads and use a suitable lubricant. I used a spray silicone that dries. It actually ruined some motorbike brake pistons (too slippery) so it does work and I've not had a problem with 1.2 plug leads.I like this idea. I'm thinking that if you used a fine hypodermic filled with liquid silicone, you might be able to reuse the leads.

One very useful addition to your toolkit would be a syringe fitted with a drawup needle; safer than the sharp pointy ones and readily available from any pharmacy. It's an excellent way to get small amounts of lubricants in the exact place they're needed, and nowhere else.If you have the syringe and lubricant why not

You can also use them with other materials (sealants for example) when precise placement is required.

Last edited:

Small 1/4 victory. The tool arrived and gave me much more leverage than the other one I bought or my bare hands. The lead popped out after a couple of tries with minimal use of expletives. Doesn't appear damaged or fused to the plug.

To my surprise the spark plug itself came out very easily. The previous owner did replace them at some point but only NGK copper plugs which seem to have worn quite a bit (gap has widened, electrode is worn nearly invisible). So that explains a lot.

I've only done the one furthest to the driver's side but it seems to have gotten rid of the phantom revving during idle so it's possible I might have got the culprit. Hoping it might solve the intermittent misfire issue but we'll have to see. I went with the NGK DCPR7EIX 6046 (iridium).

I'll replace the rest later as it's dark now but 1/4 is good enough for now having never replaced a spark plug before.

The tool I got was on Amazon UK called "Sealey VS867 Spark Plug Pliers, 300mm". Also grabbed a torque wrench and a Halfords Advanced 100pc socket set which was definitely worth it.

To my surprise the spark plug itself came out very easily. The previous owner did replace them at some point but only NGK copper plugs which seem to have worn quite a bit (gap has widened, electrode is worn nearly invisible). So that explains a lot.

I've only done the one furthest to the driver's side but it seems to have gotten rid of the phantom revving during idle so it's possible I might have got the culprit. Hoping it might solve the intermittent misfire issue but we'll have to see. I went with the NGK DCPR7EIX 6046 (iridium).

I'll replace the rest later as it's dark now but 1/4 is good enough for now having never replaced a spark plug before.

The tool I got was on Amazon UK called "Sealey VS867 Spark Plug Pliers, 300mm". Also grabbed a torque wrench and a Halfords Advanced 100pc socket set which was definitely worth it.

Well done on getting the first one changed

Ngk have a trivalent coating, as well as preventing corrosion it acts a release agent, no anti seize should be applied

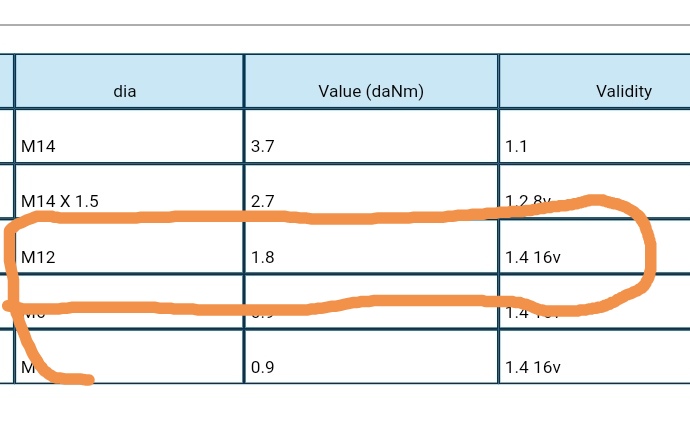

A lot sites wrongly quote the torque setting. This is understandable as there were two sizes fitted to the Panda, and 1.1 and 1.2 are torqued differently

Fiat's most up to date eLean only lists the torque for the older 14mm plugs on the 1.1 and 1.2

I torque the 12mm plugs to the 100hp spec which is 18Nm and is also to Ngk recomandation for 12mm plugs

Just noticed the autodoc video is way off first of they are using the setting for the older 14mm plugs and use copper grease which would require a reduction of 30% so if you follow the video and are using 12mm plug tighten them the same would be twice the recommended

Or maybe I have lb/ft, nm, or something messed up in my head

Could someone please check, I also beleive the Haynes manual lists the torque for the older lager plug

Ngk have a trivalent coating, as well as preventing corrosion it acts a release agent, no anti seize should be applied

A lot sites wrongly quote the torque setting. This is understandable as there were two sizes fitted to the Panda, and 1.1 and 1.2 are torqued differently

Fiat's most up to date eLean only lists the torque for the older 14mm plugs on the 1.1 and 1.2

I torque the 12mm plugs to the 100hp spec which is 18Nm and is also to Ngk recomandation for 12mm plugs

Just noticed the autodoc video is way off first of they are using the setting for the older 14mm plugs and use copper grease which would require a reduction of 30% so if you follow the video and are using 12mm plug tighten them the same would be twice the recommended

Or maybe I have lb/ft, nm, or something messed up in my head

Could someone please check, I also beleive the Haynes manual lists the torque for the older lager plug

Last edited:

I torque the 12mm plugs to the 100hp spec which is 18Nm and is also to Ngk recomandation for 12mm plugs

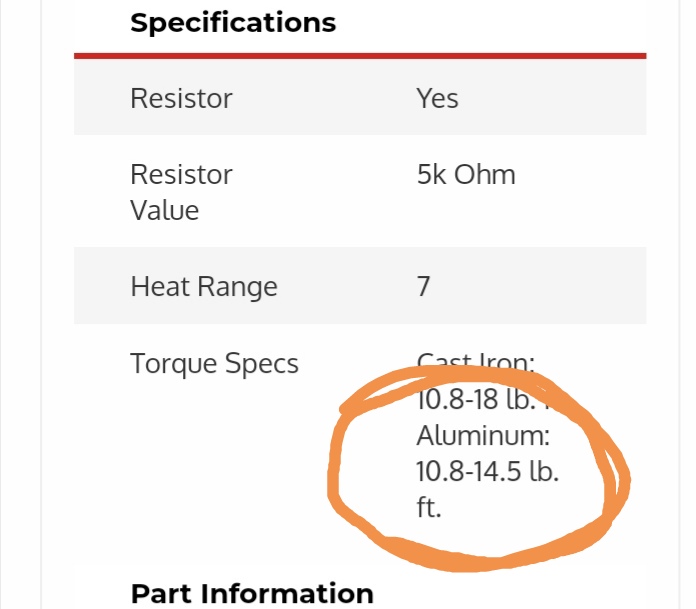

18Nm (= -13.3 ft lb) is just fine for 12mm plugs into an alloy head.Could someone please check, I also beleive the Haynes manual lists the torque for the older lager plug

That figure is well within the NGK recommended range of 10.6-14.5 ft lb (see NGK table below)

Attachments

Note also NGK's warning that the recommended torque settings are for a cold engine.

- Joined

- Sep 14, 2009

- Messages

- 19,924

- Points

- 3,959

My mechanic said it's very important to NOT under-tighten the spark plug. The stresses and pressure hitting the plug will weaken the threads if it's not tight enough. I would follow NGK to the letter and NOT use any anti seize.

Agreed. I'm following the NGK specifications to the letter. No anti seize or copper grease (after all I'm trying to fix misfires). NGK do not recommend using any anti-seize and to leave them dry as the come:My mechanic said it's very important to NOT under-tighten the spark plug. The stresses and pressure hitting the plug will weaken the threads if it's not tight enough. I would follow NGK to the letter and NOT use any anti seize.

5 Things You Should Know About Spark Plugs

The five things you should know about spark plugs include information on anti-seize, corona stain, gapping fine wire, torque and copper spark plugs.

ngksparkplugs.com

ngksparkplugs.com

As for the torque specs I went for 17 nm (after hand tightening):

10.8 ft lbs = 14.642833842 nm

14.5 ft lbs = 19.65936025 nm

(14.642833842 nm + 19.65936025 nm) / 2 = 17.151097 nm

All seems okay. I still need to replace the rest now I've got my car back (timing belt needed replacing and I'm not brave enough

Also dumb question. Do I need to go OEM when replacing the ignition leads or will compatible generic ones suffice? E.g. EuroParts has starline ones available:

www.eurocarparts.com

www.eurocarparts.com

I can't find what Fiat used for OEM online. NGK again?

Starline Ignition Lead | Euro Car Parts

Starline Ignition Lead at the lowest UK prices from Euro Car Parts UK’s No.1 for Car Accessories, Car Styling & Car Care. Buy today Online, In store or by Phone + Branches Nationwide – Next Day UK Free Delivery.

I can't find what Fiat used for OEM online. NGK again?

FCA made inhouse probably by Magneti Marelli as at the time Fiat owned. I had some here I pickup from the breakers with a coil, I am pretty sure I have checked and they aren't matked with a manufacture.I can't find what Fiat used for OEM online. NGK again?

Very good never needed to replace one

But replacement Magneti Marelli are not of the same quality, fragile has been reported by some people. It's not unusual to make different parts for the the manufacture and for retail

Never used starline so have no idea., NGK is what's supplied by most motor factors so should be reliable.

Back in the day, materials used weren't as good and HT leads were an annual change

I don't see an requirement to change in the routine maintenance plan

All 4 replaced now, engine seems smoother anecdotally. Had a minor battle with the 2nd to the left plug and the leads needed some convincing but all sorted now.

Unfortunately there was one casualty of me overtightening bolts on the airbox. The bolt to the driver's side at the back was tightened too much and the thread came off.

Now I can't get the bolt out of the thread and I'm not sure how to replace it if I could. You live and learn I guess, all the others are fine, but I'd like to fix it.

Unfortunately there was one casualty of me overtightening bolts on the airbox. The bolt to the driver's side at the back was tightened too much and the thread came off.

Now I can't get the bolt out of the thread and I'm not sure how to replace it if I could. You live and learn I guess, all the others are fine, but I'd like to fix it.

Without see it, it's hard to adviseAll 4 replaced now, engine seems smoother anecdotally. Had a minor battle with the 2nd to the left plug and the leads needed some convincing but all sorted now.

Unfortunately there was one casualty of me overtightening bolts on the airbox. The bolt to the driver's side at the back was tightened too much and the thread came off.

Now I can't get the bolt out of the thread and I'm not sure how to replace it if I could. You live and learn I guess, all the others are fine, but I'd like to fix it.

If there's 5mm or more sticking up then mole grips(vice grip or locking pliers) should work

If it's only a few mm is stick up, you might be able to cut a slot in it and wind it out with a flat blade screwdriver

The easiest would be to ask a a friendly local garage to weld something on the top

You can drill and use a square cut easy out extractor

The airbox on mine is screwed to the cam cover, if yours is the same, as a last resort this could be changed for a second hand one, there's at least three different ones, you will need a new gasket and some sealent

- Joined

- Sep 14, 2009

- Messages

- 19,924

- Points

- 3,959

Silly idea maybe. Can you use a nut and bolt?

The biggest pain about doing plugs is the new fancy bendy ends on the extension bars tend to let go before the socket comes off the plug. Not so much a problem for the basic fiats, but for 16v engines the plugs are normally buried deep in the middle of the head and getting the socket out can be a fun.

I'd still be careful on the torque wrench, only use it for a final check, not to wind the plug in. By hand is best, feel the thread is clean on the way down, then with ratchet handle as the compression washer crushes, then use the torque wrench if you must (I've never used one for spark plugs)

I'd still be careful on the torque wrench, only use it for a final check, not to wind the plug in. By hand is best, feel the thread is clean on the way down, then with ratchet handle as the compression washer crushes, then use the torque wrench if you must (I've never used one for spark plugs)

- Joined

- Sep 14, 2009

- Messages

- 19,924

- Points

- 3,959

This why I like my long plug socket. It's about 8 or 9 inches long. No extension bars needed.

Last edited:

Instead of saying the plugs are angled I should have posted a photo

Too late to add it to the original post now but here a photo from the back for referance

Imagine a centre line down the egine

The two on either side point slightly towards it

Square oil cap 12mm spark plugs onwards follow this layout. Neve worked on the early 14mm plug fire engine

Too late to add it to the original post now but here a photo from the back for referance

Imagine a centre line down the egine

The two on either side point slightly towards it

Square oil cap 12mm spark plugs onwards follow this layout. Neve worked on the early 14mm plug fire engine

Similar threads

- Replies

- 36

- Views

- 546

- Replies

- 10

- Views

- 238