Head on and torqued down. All going well (so far). I marked the timing belt hoping to just put everything back as was, but I think the belt might have moved and I don’t want to risk putting all back together and regret not checking it and doing it properly. Do you know the timing marks/pegs? I have a late so could knock to do pegs if needed.

Thanks Tom

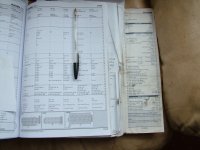

Apart from the flywheel locking bit I don't think you need to make up timing tools, just line up the marks as in this manual.

If you take your time and follow the timing manual details you should have no problem, I have done many in the past, mostly in Iveco Daily's.

You don't have to time the injector pump on the JTD, so all you need is TDC mark on crank and the cam pointers lined up.

I trust the pistons were out of the way when you fitted the cylinder head or you may bend valves!!!

When you are sure timing is correct and all tensioners etc. tight, then turn engine by hand at least two full revolutions. to make sure no valve to piston contact.

Ideally you should fit a new cam belt and guide bearings etc.

By the way, what was the reason for cylinder head off in the first place? If head gasket then head should have been checked for "flatness" with a straight edge and feeler gauge, if out then head would have needed skimming/machining flat again, also the cause of the over heating needs to have been fixed as head gaskets do not just blow on their own.

Also take care when fitting plastic timing cover etc. as I have heard of cam belt failures by not fitting spacers etc. correctly and belt tensioner failing.

Most of it is common sense if you take your time.