newbie fiat

New member

- Joined

- Aug 4, 2016

- Messages

- 96

- Points

- 27

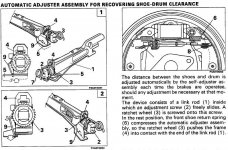

Hi, I replaced the drums and shoes on my 2005 panda yesterday but couldn't get the handbrake working. I'm aware of the adjuster cable in the cabin and adjusted that till it wouldn't go tighter. The auto adjusters seem to be at fault but after a clean up they look brand new and not worn at all. I just think I'm not setting the up right. I'm aware the handbrake cable has to be loose while sorting the adjusters

I'll attach a video if I can figure out how but the entire brass bar gets pulled out and moves the spline away from the metal plate its supposed to click against.

I'll attach a video if I can figure out how but the entire brass bar gets pulled out and moves the spline away from the metal plate its supposed to click against.