Hi Folks,

My pump failed about two ago and had got it repaired by a shop, which failed again in a weeks time due to an internal short. It's now repaired again and working quite well. However, I'd like to get this replaced ASAP.

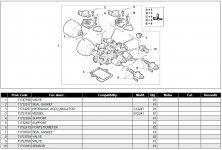

Searching though eBay and other places, I find that Alfa 147 pump looks exactly like the one I need. Has anyone here tried this motor?

On a secondary note, how often should this pump activate on Neutral? Mine turns on every 10s ish. I don't see any transmission fluid leaks though.

Thanks a lot.

Asanka.

My pump failed about two ago and had got it repaired by a shop, which failed again in a weeks time due to an internal short. It's now repaired again and working quite well. However, I'd like to get this replaced ASAP.

Searching though eBay and other places, I find that Alfa 147 pump looks exactly like the one I need. Has anyone here tried this motor?

On a secondary note, how often should this pump activate on Neutral? Mine turns on every 10s ish. I don't see any transmission fluid leaks though.

Thanks a lot.

Asanka.