Leaky axle seals replacement guide (five-speed manual gearbox C514.5). Not so complicated, but not for complete beginners (definitely not for the very first DIY job).

When you see puddle of oil under the car or smell burnt oil, it's typically (in Grande Punto) bad "breather hoses" (Guide) or valve cover gasket, maybe oil pan or some engine seals (cam or crank shaft). But engine oil and gearbox oils have different scent (also when "cooking"). You should be able to tell (smell) the difference.

Mine was dripping on the exhaust pipe. Gearbox was completely wet (so there was no way to spot the leak source). So first step is to clean the gearbox (watch out, you can flood the clutch and ruin it) and engine (but carefully, electronics). Then look again.

Right side, longer axle was leaking.

Left (short) one was "OK" (much better than Right).

Oil was sprayed up on the engine intake manifold and then dripping on the alternator...

By the way. Most common leak spot is the gear selector seal (check this Guide). When it fails, oil is pouring on the short (left) axle mostly (and gearbox is wet on the top). Check it too (actually check it first). Mine is a bit greasy (will be fixed soon).

Other source of oil leak may be main shaft seal (inside the "bell" housing).

Seal sizes, dimensions, part numbers. There is a Left (36x56x10/13,5) and Right (36x54x10/13,5) one. Better replace both (even when only one is leaky).

Prepare for the job couple days before. Spray some multipurpose/penetrant oil on all bolts/nuts and joints that will be detached. Few drops every day. Such chemicals work if you give em' enough (hours, days) time to soak (impossible in seconds or few minutes).

Axle nuts are 32 mm hex here (thread is M22x1,5). By the way, other, more powerful engines (for example Diesels) have bigger shafts (so thread and nut is bigger too, like 36 mm hex, M24 thread). There is a lot of (mis)information in the internet (what's the hex size). If you want to be sure, just pop the wheel and check (measure) yours (and buy suitable socket - in most cases it must be "deep socket", sometimes special, thin wall).

Un-secure the nut (punch, old screwdriver, or so) and undo it (but just a bit, do not remove it yet) while car is still on all 4 wheels (and wheel is secured, blocked somehow - brick, wood, to prevent spinning). Use good tools, handles and sockets with bigger square, like 3/4" (don't ruin your 1/2" set).

Next undo the steering tie rod end. Inspect it (cracked boots, damaged/loose joint). All bolts/nuts will be 16 or 17 mm from now on. Not much tools needed for this whole job.

And swaybar end link (one joint, top or bottom, doesn't matter), prybar will help to remove (and install it back later). Inspect it too.

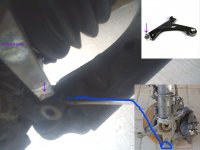

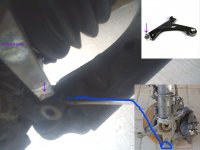

Track control arm ball joint. Pop it out too. Remove bolt and nut. Wedge something into the gap (but not too crazy) and hit, punch the joint out of the knuckle. Many universal ball joint pullers will not fit here (or will damage the rubber - "wishbone" ball joint boot and/or axle CV joint boot).

Now you can maneuver the axle out from the hub. Turn (max. left or right) and pull the shock-absorber assembly towards you. It will free up the axle (CV joint). Just mind the hoses (brake lines) and wires/cables (ABS sensor).

Drain the gearbox oil (Guide). Drain plug is 8 mm. Fill plug 12 mm internal hex.

Most difficult part of the job - prying/jerking out the inner joint housing from the gearbox differential. Hold it and pull it/wiggle it with one hand, while other is pushing/prying with some small prybar or big flat screwdriver. Not that hard, but tricky (you must generate proper impact to overcome, pop the retainer clip out). Mind the gearbox aluminium housing (don't crack it).

Once you "get it" it will be easy task next time, everytime. Axle popped out. C-clip seems to be a bit loose, but it will be OK. Take pictures and/or measure how deep is the seal installed.

They are all the same, most gearboxes (C514 series) in multiple Fiat models. And seals are installed same way (same depth).

Second most important thing. You know the seal dimensions (diameters). Prepare some install tool, improvise, piece of pipe, bushing, plastic hydraulic fitting, bearing race, or old seal etc. Lubricate and tap the seals into place, slowly, stop and check often, don't tilt/crook it too much during the job.

Other side is the same job. But seals (Left/Right) may be at different depths a bit, pay attention. Do not grind (to "clean") the axles, seal mating/riding surfaces, clean it (solvent) and leave it as it is. Not much you can do if there are grooves (maybe install seals +/- 1 mm deeper/shallower, intentionally).

Peep this. Document about seals, for example jump to pages 20, 21: https://www.parker.com/literature/Engineered Polymer Systems/5350.pdf

You can not control this while grinding freehand (rubbing with sand papers etc.), surface finish and scratches forming "lead" (you can get "pumping" action and push oil out of the gearbox - not all, and not instantly, but it will spoil the performance of the new seals).

Axles will (should) gently pop back into the gearbox - use some grease or thick oil to help. Put everything back together. Fill the gearbox. Make sure axle nuts are "guten-tight" (as they say in german-english).

When you see puddle of oil under the car or smell burnt oil, it's typically (in Grande Punto) bad "breather hoses" (Guide) or valve cover gasket, maybe oil pan or some engine seals (cam or crank shaft). But engine oil and gearbox oils have different scent (also when "cooking"). You should be able to tell (smell) the difference.

Mine was dripping on the exhaust pipe. Gearbox was completely wet (so there was no way to spot the leak source). So first step is to clean the gearbox (watch out, you can flood the clutch and ruin it) and engine (but carefully, electronics). Then look again.

Right side, longer axle was leaking.

Left (short) one was "OK" (much better than Right).

Oil was sprayed up on the engine intake manifold and then dripping on the alternator...

By the way. Most common leak spot is the gear selector seal (check this Guide). When it fails, oil is pouring on the short (left) axle mostly (and gearbox is wet on the top). Check it too (actually check it first). Mine is a bit greasy (will be fixed soon).

Other source of oil leak may be main shaft seal (inside the "bell" housing).

Seal sizes, dimensions, part numbers. There is a Left (36x56x10/13,5) and Right (36x54x10/13,5) one. Better replace both (even when only one is leaky).

Prepare for the job couple days before. Spray some multipurpose/penetrant oil on all bolts/nuts and joints that will be detached. Few drops every day. Such chemicals work if you give em' enough (hours, days) time to soak (impossible in seconds or few minutes).

Axle nuts are 32 mm hex here (thread is M22x1,5). By the way, other, more powerful engines (for example Diesels) have bigger shafts (so thread and nut is bigger too, like 36 mm hex, M24 thread). There is a lot of (mis)information in the internet (what's the hex size). If you want to be sure, just pop the wheel and check (measure) yours (and buy suitable socket - in most cases it must be "deep socket", sometimes special, thin wall).

Un-secure the nut (punch, old screwdriver, or so) and undo it (but just a bit, do not remove it yet) while car is still on all 4 wheels (and wheel is secured, blocked somehow - brick, wood, to prevent spinning). Use good tools, handles and sockets with bigger square, like 3/4" (don't ruin your 1/2" set).

Next undo the steering tie rod end. Inspect it (cracked boots, damaged/loose joint). All bolts/nuts will be 16 or 17 mm from now on. Not much tools needed for this whole job.

And swaybar end link (one joint, top or bottom, doesn't matter), prybar will help to remove (and install it back later). Inspect it too.

Track control arm ball joint. Pop it out too. Remove bolt and nut. Wedge something into the gap (but not too crazy) and hit, punch the joint out of the knuckle. Many universal ball joint pullers will not fit here (or will damage the rubber - "wishbone" ball joint boot and/or axle CV joint boot).

Now you can maneuver the axle out from the hub. Turn (max. left or right) and pull the shock-absorber assembly towards you. It will free up the axle (CV joint). Just mind the hoses (brake lines) and wires/cables (ABS sensor).

Drain the gearbox oil (Guide). Drain plug is 8 mm. Fill plug 12 mm internal hex.

Most difficult part of the job - prying/jerking out the inner joint housing from the gearbox differential. Hold it and pull it/wiggle it with one hand, while other is pushing/prying with some small prybar or big flat screwdriver. Not that hard, but tricky (you must generate proper impact to overcome, pop the retainer clip out). Mind the gearbox aluminium housing (don't crack it).

Once you "get it" it will be easy task next time, everytime. Axle popped out. C-clip seems to be a bit loose, but it will be OK. Take pictures and/or measure how deep is the seal installed.

They are all the same, most gearboxes (C514 series) in multiple Fiat models. And seals are installed same way (same depth).

Second most important thing. You know the seal dimensions (diameters). Prepare some install tool, improvise, piece of pipe, bushing, plastic hydraulic fitting, bearing race, or old seal etc. Lubricate and tap the seals into place, slowly, stop and check often, don't tilt/crook it too much during the job.

Other side is the same job. But seals (Left/Right) may be at different depths a bit, pay attention. Do not grind (to "clean") the axles, seal mating/riding surfaces, clean it (solvent) and leave it as it is. Not much you can do if there are grooves (maybe install seals +/- 1 mm deeper/shallower, intentionally).

Peep this. Document about seals, for example jump to pages 20, 21: https://www.parker.com/literature/Engineered Polymer Systems/5350.pdf

You can not control this while grinding freehand (rubbing with sand papers etc.), surface finish and scratches forming "lead" (you can get "pumping" action and push oil out of the gearbox - not all, and not instantly, but it will spoil the performance of the new seals).

Axles will (should) gently pop back into the gearbox - use some grease or thick oil to help. Put everything back together. Fill the gearbox. Make sure axle nuts are "guten-tight" (as they say in german-english).