Introduction

Hello everyone! As the title suggests, I have decided to build a Ducati powered Fiat 500!

I have restored a couple classic American cars, some motorcycles, and have designed and built a handful of Formula SAE cars in college, but I've always wanted to build my own motorcycle powered road car.

After a decade of working at one of the largest Spacecraft companies in California, I decided to take a break and try to make this dream a reality. The car needed to be simple, lightweight, relatively cheap, and older than 1975 (California smog requirements). I have a buddy that did this with an old Honda S600, and another with a Fiat 850 spider, but I wanted to do something a bit less roadster-y. Then, as the wife and I were honeymooning in Italy, I saw the answer: the old Cinquecento.

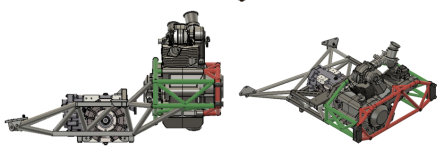

There seems to be lots of motorcycle powered 500s for hill climbing, and Z-Cars is one of the most popular swaps out there with their Suzuki Hayabusa swapped "Fiabusa" (they also make a Subaru swapped "Fubaru"), but I wanted to keep the motor air cooled (no big radiator up front) and Italian. After a bit of research, I decided to go with my favorite motorcycle engine, a Ducati 1100. The last of the big, air cooled, dry clutch L-Twins. How hilariously adorable would this car be with that noise coming out of it?

I spent a few months looking for the perfect car - something that was driveable, in decent shape, but not too nice, so I could save money up front and put it toward the swap. I ended up with a clean-ish 1974 Fiat 500 R with about 26,000 km on the clock that had been imported into the states a few years prior. The body was in pretty good shape until a strap broke towing it home resulting in a head on collision with the trailer. I minimally repaired the damaged area so I could turn the wheels full lock again, then drove it around a few months until I got the car registered.

Now that the car is legal, it's time to begin the project!

I'm looking forward to sharing the progress and hearing everyone's thoughts on the build. I have reached out to a few people individually and everyone has been extremely nice and very helpful!

I have restored a couple classic American cars, some motorcycles, and have designed and built a handful of Formula SAE cars in college, but I've always wanted to build my own motorcycle powered road car.

After a decade of working at one of the largest Spacecraft companies in California, I decided to take a break and try to make this dream a reality. The car needed to be simple, lightweight, relatively cheap, and older than 1975 (California smog requirements). I have a buddy that did this with an old Honda S600, and another with a Fiat 850 spider, but I wanted to do something a bit less roadster-y. Then, as the wife and I were honeymooning in Italy, I saw the answer: the old Cinquecento.

There seems to be lots of motorcycle powered 500s for hill climbing, and Z-Cars is one of the most popular swaps out there with their Suzuki Hayabusa swapped "Fiabusa" (they also make a Subaru swapped "Fubaru"), but I wanted to keep the motor air cooled (no big radiator up front) and Italian. After a bit of research, I decided to go with my favorite motorcycle engine, a Ducati 1100. The last of the big, air cooled, dry clutch L-Twins. How hilariously adorable would this car be with that noise coming out of it?

I spent a few months looking for the perfect car - something that was driveable, in decent shape, but not too nice, so I could save money up front and put it toward the swap. I ended up with a clean-ish 1974 Fiat 500 R with about 26,000 km on the clock that had been imported into the states a few years prior. The body was in pretty good shape until a strap broke towing it home resulting in a head on collision with the trailer. I minimally repaired the damaged area so I could turn the wheels full lock again, then drove it around a few months until I got the car registered.

Now that the car is legal, it's time to begin the project!

I'm looking forward to sharing the progress and hearing everyone's thoughts on the build. I have reached out to a few people individually and everyone has been extremely nice and very helpful!