Looking back at it and at my pictures since I first set the timing, February this year, I'd say you probably have the camshaft backwards one tooth. So revolving the engine with one bit on the crankshaft (like in the video) one time should do the trick and have them timed spot on.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Timing issue

- Thread starter Scottieo321

- Start date

Currently reading:

Technical Timing issue

Scottieo321

Member

So would this be turning anticlockwise or clockwise? (May seem stupid to ask but I'd rather ask and have it there than not you know) I've read before and seen videos ect all saying should never turn crank anticlockwise with the belt tensioned, is this 100% correct?Looking back at it and at my pictures since I first set the timing, February this year, I'd say you probably have the camshaft backwards one tooth. So revolving the engine with one bit on the crankshaft (like in the video) one time should do the trick and have them timed spot on.

I'll give it a go doing it this way see if it makes any difference to it, if it does and it's still not great but better then I'll try it again to see if I can get it as close to 10° as possible this way, if it fails then will retime it your way and see if that works.

Only thing is you seem to have the similar looking engine to this one but yours is dipped in at that mark on engine and you have the mark on dipstick holder yet this one has neither. What year is yours?

Turning clockwise!

I'm with those that say not to turn the engine anticlockwise. The guy in the video does turn it anticlockwise too, but I wouldn't do that.

Mine is Punto Mk2 2006 the year. Nevermind the dipstick holder mark. There is the mark on the corner of the Cylinder Head and the cam pulley also has the mark. Check again photo in post #50, that's your photo, I just circled the marks on it!

I'm with those that say not to turn the engine anticlockwise. The guy in the video does turn it anticlockwise too, but I wouldn't do that.

Mine is Punto Mk2 2006 the year. Nevermind the dipstick holder mark. There is the mark on the corner of the Cylinder Head and the cam pulley also has the mark. Check again photo in post #50, that's your photo, I just circled the marks on it!

- Joined

- Apr 22, 2018

- Messages

- 1,065

- Points

- 367

1. Now, That type of shake is not acceptable at all. There is a problem, hidden damage.

2. As far as I understand, you didn't checked the crankshaft wheel "key" (if it's broken), method was mentioned (how).

3. You can have a "good" timing looking from phonic wheel and camshaft sensors, but the pistons are somewhere else...

4. Universal OBD scanners are useless. Get FES or MES or other Fiat specific software (AlfaOBD). For now, you can't trust such data.

But wrong timing (forgot which way) can cause negative spark advance. Correct idle value is positive (0-10 degrees range) 1,2/1,4 8V.

5. Then we have other maintenance items: valve clearance, camshaft lobe lift (must be 9,50 mm).

Plus compression and fuel pressure. And intake vacuum gauge (old-school diagnostic tool, before OBD era).

2. As far as I understand, you didn't checked the crankshaft wheel "key" (if it's broken), method was mentioned (how).

3. You can have a "good" timing looking from phonic wheel and camshaft sensors, but the pistons are somewhere else...

4. Universal OBD scanners are useless. Get FES or MES or other Fiat specific software (AlfaOBD). For now, you can't trust such data.

But wrong timing (forgot which way) can cause negative spark advance. Correct idle value is positive (0-10 degrees range) 1,2/1,4 8V.

5. Then we have other maintenance items: valve clearance, camshaft lobe lift (must be 9,50 mm).

Plus compression and fuel pressure. And intake vacuum gauge (old-school diagnostic tool, before OBD era).

Scottieo321

Member

My apologies I didn't see that part about the key, I've just looked back and seen it. I don't have a day off till next Tuesday so I will take it down again and check the crank key if mikes method doesn't work as it will show there's a big issue somewhere.2. As far as I understand, you didn't checked the crankshaft wheel "key" (if it's broken), method was mentioned (how).

3. You can have a "good" timing looking from phonic wheel and camshaft sensors, but the pistons are somewhere else...

4. Universal OBD scanners are useless. Get FES or MES or other Fiat specific software (AlfaOBD). For now, you can't trust such data.

But wrong timing (forgot which way) can cause negative spark advance. Correct idle value is positive (0-10 degrees range) 1,2/1,4 8V.

5. Then we have other maintenance items: valve clearance, camshaft lobe lift (must be 9,50 mm).

Plus compression and fuel pressure. And intake vacuum gauge (old-school diagnostic tool, before OBD era).

The camshaft lobe lift you have both mentioned about the clearance on these, what are the +/- on this? Also and I know I can go looking to find out I just thought I would ask of you both how do you adjust the valves clearances? I have the tool to check them but if any are out how are they adjusted?

D'you know what I find particularly interesting about this thread? It's the fact that doing a cam belt, which seems such an easy task for us with more experience/motor trade backgrounds can turn out to be a whole barrel of worms for those with less experience. Perhaps we need to factor that in when posts like this appear?

Edit. @Scottieo321 - you make a good point about implications of the crank pulley key being sheared - and it's known to sometimes do this. I was forgetting that one! Mind you, personally I've never come across it.

Edit. @Scottieo321 - you make a good point about implications of the crank pulley key being sheared - and it's known to sometimes do this. I was forgetting that one! Mind you, personally I've never come across it.

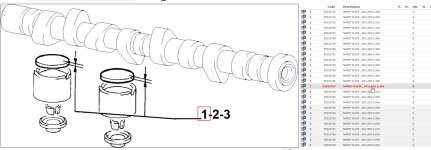

For the 1.2 8V engine the clearances are:

Inlet 0.35 +/- 0.05 mm

Outlet 0.45 +/- 0.05 mm.

To adjust them you have those adjusting shims (tappet plates) that you need to replace with the correct shim size if clearence is off.

New shim size = (measured valve clearance - specified valve clearence) + old shims size.

The shims look like this and are placed in here

Inlet 0.35 +/- 0.05 mm

Outlet 0.45 +/- 0.05 mm.

To adjust them you have those adjusting shims (tappet plates) that you need to replace with the correct shim size if clearence is off.

New shim size = (measured valve clearance - specified valve clearence) + old shims size.

The shims look like this and are placed in here

Attachments

- Joined

- Apr 22, 2018

- Messages

- 1,065

- Points

- 367

1. To check the "key", you don't have to dismantle everything. No tools needed (if your phonic wheel has a triangular cut/notch).

https://www.fiatforum.com/threads/engine-timing-setup-1-4-8v-vvt.426347/post-4790015 Flywheel + phonic wheel.

https://www.fiatforum.com/threads/engine-timing-setup-1-4-8v-vvt.426347/post-4790015 Flywheel + phonic wheel.

To be 200% sure (double check/"sanity check"), you probe the pistons (via sparkplug holes), where they are (at TDC and TDC+90).

2. Valve "lash" Guide: https://www.fiatforum.com/guides/valve-clearance-check-and-adjustment-1-4-8v.824/

Tolerance is 0,05 mm, but total (not plus/minus, it's too much). The point is not only to be in tolerance (and "call it a day"), but to set clearances equally.

3. Camshaft lobes lift same story. The problem is, when they wear unevenly. If there is a wear, but equal on all 8 lobes, it's a lesser evil.

About 0,1-0,2 mm missing (polished) makes a difference in engine performance (for example lack of power - hot engine).

Use dial indicator method (not caliper/micrometer).

4. Compression test is a good idea. For a starter (appetizer). In-cylinder pressure waveform would probably help to pinpoint the issue.

But this is still not popular (most mechanics don't use "scope"): https://www.youtube.com/results?search_query=in+cylinder+pressure+waveform+bad+timing

5. If the head was damaged (valves), it's probably still an engine head problem (valves/seats/guides)...

By the way, old eLearn (CD version) clearly states, that timing belt in Grande 1,2 8V is done with timing tools (same as 1,4 8V + VVT), so "old-school TDC method" is not needed (I mean: using tools cannot cause such trouble). But you must use full method (not mix them: TDC + one jig from the timing tool set).

To be 200% sure (double check/"sanity check"), you probe the pistons (via sparkplug holes), where they are (at TDC and TDC+90).

2. Valve "lash" Guide: https://www.fiatforum.com/guides/valve-clearance-check-and-adjustment-1-4-8v.824/

Tolerance is 0,05 mm, but total (not plus/minus, it's too much). The point is not only to be in tolerance (and "call it a day"), but to set clearances equally.

3. Camshaft lobes lift same story. The problem is, when they wear unevenly. If there is a wear, but equal on all 8 lobes, it's a lesser evil.

About 0,1-0,2 mm missing (polished) makes a difference in engine performance (for example lack of power - hot engine).

Use dial indicator method (not caliper/micrometer).

4. Compression test is a good idea. For a starter (appetizer). In-cylinder pressure waveform would probably help to pinpoint the issue.

But this is still not popular (most mechanics don't use "scope"): https://www.youtube.com/results?search_query=in+cylinder+pressure+waveform+bad+timing

5. If the head was damaged (valves), it's probably still an engine head problem (valves/seats/guides)...

By the way, old eLearn (CD version) clearly states, that timing belt in Grande 1,2 8V is done with timing tools (same as 1,4 8V + VVT), so "old-school TDC method" is not needed (I mean: using tools cannot cause such trouble). But you must use full method (not mix them: TDC + one jig from the timing tool set).

Last edited:

Scottieo321

Member

Well that's exactly it thought ain't it, some of you guys/gals have done this sort of thing for years so to you lot it's just like buttering bread (with soft butter), you'd look at it or hear it and go bish bash bosh jobs done, for likes of me the engine and fuel system are the only 2 things I've never gotten a hold of or even looked at cause I know myself I'm guna mess something up.D'you know what I find particularly interesting about this thread? It's the fact that doing a cam belt, which seems such an easy task for us with more experience/motor trade backgrounds can turn out to be a whole barrel of worms for those with less experience. Perhaps we need to factor that in when posts like this appear?

Edit. @Scottieo321 - you make a good point about implications of the crank pulley key being sheared - and it's known to sometimes do this. I was forgetting that one! Mind you, personally I've never come across it.

I think once I've done a head gasket but that took 3 attempts to do (wouldn't seal correctly nothing wrong with the head just not clean enough ).

Honestly before I started researching I just thought simple take belt off put new on like the aux belt, then when I had a little research I knew it wasn't that straightforward and I deffo knew this one wouldn't be either.

When we got the car it had (be prepared) 3rd party after market cheap a** "sports" air filter, bor exhaust, hid lights (not done correctly), oil literally pi**ING out all round the engine, coolant leak (still has slight but from pipe not into engine), never had oil change for years it was black and the amount of sludge under the car cover was ridiculous (took a lot of work), air intake pipe blocked, the bit on the top that lets engine pressure/fumes go back through air intake blocked, where the cat goes on 4/5 bolts snapped inside engine and been horribly tried to be drilled out, missing all sorts of bolts/nuts washers, body work is a wreck, lights have faults but all working correctly ? , had to change the starter too on and let's not forget the good old problem city mode makes, I had to change the whole power steering column (that left me with a scar on my head

Honestly there's still more but she's not been taken care of at all for years and I'm making it my job to bring her back to life the best I can cause I know puntos are a car for life if taken care of correctly.

Scottieo321

Member

I'm pretty sure that I checked down the sparks when at +90 but think I only checked 1+2 no all them, I know when at TDC 1+4 are top and 2+3 are bottom but will do a recheck if/when I need to.1. To check the "key", you don't have to dismantle everything. No tools needed (if your phonic wheel has a triangular cut/notch).

https://www.fiatforum.com/threads/engine-timing-setup-1-4-8v-vvt.426347/post-4790015 Flywheel + phonic wheel.

To be 200% sure (double check/"sanity check"), you probe the pistons (via sparkplug holes), where they are (at TDC and TDC+90).

2. Valve "lash" Guide: https://www.fiatforum.com/guides/valve-clearance-check-and-adjustment-1-4-8v.824/

Tolerance is 0,05 mm, but total (not plus/minus, it's too much). The point is not only to be in tolerance (and "call it a day"), but to set clearances equally.

3. Camshaft lobes lift same story. The problem is, when they wear unevenly. If there is a wear, but equal on all 8 lobes, it's a lesser evil.

About 0,1-0,2 mm missing (polished) makes a difference in engine performance (for example lack of power - hot engine).

Use dial indicator method (not caliper/micrometer).

4. Compression test is a good idea. For a starter (appetizer). In-cylinder pressure waveform would probably help to pinpoint the issue.

But this is still not popular (most mechanics don't use "scope"): https://www.youtube.com/results?search_query=in+cylinder+pressure+waveform+bad+timing

5. If the head was damaged (valves), it's probably still an engine head problem (valves/seats/guides)...

By the way, old eLearn (CD version) clearly states, that timing belt in Grande 1,2 8V is done with timing tools (same as 1,4 8V + VVT), so "old-school TDC method" is not needed (I mean: using tools cannot cause such trouble). But you must use full method (not mix them: TDC + one jig from the timing tool set).

View attachment 466955

I'll check the valve stems when I next get time to do so to see, I think I've done it before and being inexperienced only checked 1 or 2. But I will do a full check.

Last compression test I done everything was perfect, all hitting 200 maybe 0.01 less on one of them and they held compression too but again will recheck (it does no harm).

It's a shame that all guides with pictures show the crank without any marker or the dimple on as that would be a great help to know which way is the right way and not have to mess it up scratch your head for days and then have to ask you guys about a simple enough job you know.

Scottieo321

Member

No problem thank you least I know what to look for when needing new (I say when cause it's guna be out I know it) also thank you for the measurement I now know how to calculate that up correctly.For the 1.2 8V engine the clearances are:

Inlet 0.35 +/- 0.05 mm

Outlet 0.45 +/- 0.05 mm.

To adjust them you have those adjusting shims (tappet plates) that you need to replace with the correct shim size if clearence is off.

New shim size = (measured valve clearance - specified valve clearence) + old shims size.

The shims look like this and are placed in here

Scottieo321

Member

So going by the guide for the shims they should be at around 0.30 for intake and 0.40 for exhaust.

My question is how do they need to be checked? Is it where they slide between lobe and shim nicely or where you need to give them just a little push the go in to rest it?

This is them just sliding in and out no resistance or anything just nicely.

Intake 0.30

2- 0.33 shim 2.43 = +0.03 = 2.46 needed

4- 0.25 shim 2.38 = -0.05 = 2.33

5- 0.38 shim 2.47 = +0.08 = 2.55

7- 0.40 shim 2.37 = +0.10 = 2.47

Exhaust 0.40

1- 0.35 shim 2.32 = -0.05 = 2.27

3- 0.33 shim 2.40 = -0.07 = 2.33

6- 0.30 shim 2.29 = -0.10 = 2.19

8- 0.35 shim 2.28 = -0.05 = 2.23

If this is the case then all but 1 needs replacing which will be a big expense.

If it's the tight fitting and I can get away with it I only need to replace 3 and all will be within tolerance in the + but all won't be at the same.

My question is how do they need to be checked? Is it where they slide between lobe and shim nicely or where you need to give them just a little push the go in to rest it?

This is them just sliding in and out no resistance or anything just nicely.

Intake 0.30

2- 0.33 shim 2.43 = +0.03 = 2.46 needed

4- 0.25 shim 2.38 = -0.05 = 2.33

5- 0.38 shim 2.47 = +0.08 = 2.55

7- 0.40 shim 2.37 = +0.10 = 2.47

Exhaust 0.40

1- 0.35 shim 2.32 = -0.05 = 2.27

3- 0.33 shim 2.40 = -0.07 = 2.33

6- 0.30 shim 2.29 = -0.10 = 2.19

8- 0.35 shim 2.28 = -0.05 = 2.23

If this is the case then all but 1 needs replacing which will be a big expense.

If it's the tight fitting and I can get away with it I only need to replace 3 and all will be within tolerance in the + but all won't be at the same.

- Joined

- Apr 22, 2018

- Messages

- 1,065

- Points

- 367

Zero clearance during measurement gives the feedback that feels like a slight drag, small resistance.

Same for calibrating tools, like micrometer + gauge blocks = when you're on size, there is a drag (should be).

That's how you develop "the feel" (how much force is needed/expected during various checks, using different tools).

Your calculations are OK, here is a (re)check using old-school program (non-english unfortunately), works only under DOS and Windows 32-bit.

It utilizes mouse to navigate. Download (zip file), if someone is interested: LINK. Nothing to write home about. Translation (table)...

Valve, Exhaust/Intake / Current shim is / Lash measured / Desired lash is / New shim should be / EPER part number / "Freccia".

Grande model is default (clearances 0,40 / 0,30). It spits also rounded values for aftermarket shims (0,05 mm increment). Brands like "Metelli" or "Freccia".

You can swap 3 or 4 existing shims (so only 4 or 5 to be purchased, not all eight)... Example below (options, alternatives).

Again, main goal is to be equal/even (lash), then the value (is it perfect, or smaller, or a bit bigger - but make ALL clearances bigger, that's the point). Being "in tolerance" for the sake of it, is NOT a primary goal of the valve lash adjustment procedure (it's a secondary goal).

But, first of all, make sure that your valves are not looking like that (use USB endoscope). Adjusting lash in such case is pointless, doesn't make sense.

Next thing to do (after sorting out the lash) will be the ignition coils module. New strong one makes sparks at 1,5 ms (dwell, "coil charge time" in MES), but when it's old and weak it needs more "charging" (dwell jumps above 2,0 ms - max. is 2,5).

Same for calibrating tools, like micrometer + gauge blocks = when you're on size, there is a drag (should be).

That's how you develop "the feel" (how much force is needed/expected during various checks, using different tools).

Your calculations are OK, here is a (re)check using old-school program (non-english unfortunately), works only under DOS and Windows 32-bit.

It utilizes mouse to navigate. Download (zip file), if someone is interested: LINK. Nothing to write home about. Translation (table)...

Valve, Exhaust/Intake / Current shim is / Lash measured / Desired lash is / New shim should be / EPER part number / "Freccia".

Grande model is default (clearances 0,40 / 0,30). It spits also rounded values for aftermarket shims (0,05 mm increment). Brands like "Metelli" or "Freccia".

You can swap 3 or 4 existing shims (so only 4 or 5 to be purchased, not all eight)... Example below (options, alternatives).

Again, main goal is to be equal/even (lash), then the value (is it perfect, or smaller, or a bit bigger - but make ALL clearances bigger, that's the point). Being "in tolerance" for the sake of it, is NOT a primary goal of the valve lash adjustment procedure (it's a secondary goal).

But, first of all, make sure that your valves are not looking like that (use USB endoscope). Adjusting lash in such case is pointless, doesn't make sense.

Next thing to do (after sorting out the lash) will be the ignition coils module. New strong one makes sparks at 1,5 ms (dwell, "coil charge time" in MES), but when it's old and weak it needs more "charging" (dwell jumps above 2,0 ms - max. is 2,5).

Last edited:

Scottieo321

Member

Hi sorry been a few weeks since my last post.Zero clearance during measurement gives the feedback that feels like a slight drag, small resistance.

Same for calibrating tools, like micrometer + gauge blocks = when you're on size, there is a drag (should be).

That's how you develop "the feel" (how much force is needed/expected during various checks, using different tools).

Your calculations are OK, here is a (re)check using old-school program (non-english unfortunately), works only under DOS and Windows 32-bit.

It utilizes mouse to navigate. Download (zip file), if someone is interested: LINK. Nothing to write home about. Translation (table)...

Valve, Exhaust/Intake / Current shim is / Lash measured / Desired lash is / New shim should be / EPER part number / "Freccia".

View attachment 467255

Grande model is default (clearances 0,40 / 0,30). It spits also rounded values for aftermarket shims (0,05 mm increment). Brands like "Metelli" or "Freccia".

You can swap 3 or 4 existing shims (so only 4 or 5 to be purchased, not all eight)... Example below (options, alternatives).

View attachment 467262

Again, main goal is to be equal/even (lash), then the value (is it perfect, or smaller, or a bit bigger - but make ALL clearances bigger, that's the point). Being "in tolerance" for the sake of it, is NOT a primary goal of the valve lash adjustment procedure (it's a secondary goal).

But, first of all, make sure that your valves are not looking like that (use USB endoscope). Adjusting lash in such case is pointless, doesn't make sense.

View attachment 467260

Next thing to do (after sorting out the lash) will be the ignition coils module. New strong one makes sparks at 1,5 ms (dwell, "coil charge time" in MES), but when it's old and weak it needs more "charging" (dwell jumps above 2,0 ms - max. is 2,5).

Ran into a problem where a valve snapped luckily only made a slight indent on the piston so been doing my homework slowly and surely.

I decided it was easier (for myself) to replace all the valves and the stem seals (also done the valve seating with correct tools so now shiny), put cam shaft back on the head tested gaps and rearranged where needed. All but 1 is on the lower end being at a -0.05mm (no further gaps in them all) and no.5 is right on the money at 0.30mm.

Firstly wanting to check will this run when back together?

Also wanting to check since both are apart I know I need cam to have the tool to fit at the end being that is correct timing place for it but what point is best for the crank?

Having them all half mast or 1/4 at top before putting everything back together?

Also top of the engine block is fine I've gone over a few times with a straight edge and checked gaps as well as bottom of head is fine, both clean and tidy (best it can be without skimming).

Have full new gasket set along with bolts (I don't like to reuse when it's for torque in engine better to be safe than sorry)

All seals that come with it have been fitted and old thrown away.

This is my last point of call after research just to ask the questions and get them answered that way full learning has been acquired.

Scottieo321

Member

These taken before cleaning fully ect as you can see 7 snapped, this is the same one that was previously replaced.

Attachments

-

IMG20250520125656.jpg4.4 MB · Views: 45

IMG20250520125656.jpg4.4 MB · Views: 45 -

IMG20250520125701.jpg4.8 MB · Views: 40

IMG20250520125701.jpg4.8 MB · Views: 40 -

IMG20250520125705.jpg4.5 MB · Views: 35

IMG20250520125705.jpg4.5 MB · Views: 35 -

IMG20250520125708.jpg4.8 MB · Views: 40

IMG20250520125708.jpg4.8 MB · Views: 40 -

IMG20250520125719.jpg6.2 MB · Views: 35

IMG20250520125719.jpg6.2 MB · Views: 35 -

IMG20250520125731.jpg5.4 MB · Views: 38

IMG20250520125731.jpg5.4 MB · Views: 38 -

IMG20250520125733.jpg5.3 MB · Views: 45

IMG20250520125733.jpg5.3 MB · Views: 45 -

IMG20250520125735.jpg5.4 MB · Views: 36

IMG20250520125735.jpg5.4 MB · Views: 36 -

IMG20250520125738.jpg5 MB · Views: 35

IMG20250520125738.jpg5 MB · Views: 35

Scottieo321

Member

Firstly wanting to check will this run when back together?

I hope it works out! I have my fingers crossed.

I can't offer any advice, if the rebuild fails it'll do so in a way thats impossible for me to predict.

I'm very interested to know what happens though.

Similar threads

- Replies

- 15

- Views

- 888