Last edited:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Seicento MPI Turbo ECU

- Thread starter woj

- Start date

Currently reading:

Technical Seicento MPI Turbo ECU

Wife would kill me if I bought a Seicento

Only because you'd spend more time servicing it than her.

Anyhow, I am getting closer and closer to indeed have a practical stand alone out of this thing. Some things are yet to be tested to confirm.

The important factor missing here is some intuitive software so people who can't see the Matrix can alter the mapping. Maybe you can write some.

I guess the other way (the way you are planning?) is to sell pre flashed ECU's for specific modifications but since every Cento (especially Turbocharged) contains bespoke parts for the conversion they will likely require a different map. I'm assuming the auto adaption will do its thing to a small degree but unless you can add a knock and wideband to your armory that's still not much use? Alternitively you could travel the world supplying these mapping them on site but I guess that might make the cost prohibitive. Of course the final option is to sell a complete kit with all the required parts manufactured the same.

Keep are the awsome work anyhow.

The important factor missing here is some intuitive software so people who can't see the Matrix can alter the mapping. Maybe you can write some.

This intuitive, no? Why would I write anything myself while there is TunerPro out there. Some things are and work better than in the DET/EMU software

Attachments

This intuitive, no? Why would I write anything myself while there is TunerPro out there. Some things are and work better than in the DET/EMU software

It has no realtime wideband input/overlay, better than a ecu specific software? No mate, the reason the DTA is so popular is because its intuitive easy to tune software which gets good results fast for the operator. This is the main reason people ditch the factory kit, not because the aftermarkets are better but because the software is more user friendly.

Edit: also its ability to easly enable/disable feature and remove the stuff we don't want. All stuff you can do but your buyer won't be able to unless you give them a way to do it. Sorry but Tuner Pro and its derivatives are too geeky for your average Joe even with excellent car and tuning knowledge. I can see what you have done with you specific ECU list and plugin etc. I take my hat off to you Woj for your excellent engineering however it's still pretty hard going for your average user. Maybe your clued up operator will be fine with this but maybe you can do something to make it easier for the road tuning chaps out there?

Last edited:

You are in principle right, but (a) I sense you have never used TunerPro, (b) the reason for popularity of SA system lies elsewhere in my opinion (and this is something I cannot fix for the moment). Yes you can live trace ECU feedback in Tuner and you can trace wideband (for now it has only plugin for LC, doing one for Zeitronix is deep on my todo list). Providing a user friendly view is also no problem, you tag your tables with "levels" and choose in the GUI upto which level your current interest is. You want to see and tune only the spark and VE table, no problem.

But point (b) is more crucial. I have no way of doing live remaps, that is pressing things in TunerPro and observing AFR live to see how this changes things. And this is a matter of the ECU architecture (relatively small RAM) than anything else.

But point (b) is more crucial. I have no way of doing live remaps, that is pressing things in TunerPro and observing AFR live to see how this changes things. And this is a matter of the ECU architecture (relatively small RAM) than anything else.

You are in principle right, but (a) I sense you have never used TunerPro.

True, I looked around it briefly with no file loaded, I can see that you have done the ground work to make it much easier and appretiate this.

Yes you can live trace ECU feedback in Tuner and you can trace wideband (for now it has only plugin for LC, doing one for Zeitronix is deep on my todo list). Providing a user friendly view is also no problem, you tag your tables with "levels" and choose in the GUI upto which level your current interest is. You want to see and tune only the spark and VE table, no problem.

This is all good stuff and I'm sure your interface will work well, however bear in mind on your average SA (not DET3) you just need to fit a sensor to the ECU not faff about with a seperate gauge and analogue input like we do.

But point (b) is more crucial. I have no way of doing live remaps, that is pressing things in TunerPro and observing AFR live to see how this changes things. And this is a matter of the ECU architecture (relatively small RAM) than anything else.

I thought you'd overcome this issue with the flashable chipset.

Of course this is still very doable but a slow process in comparisson to an SA. This is still quite a common way of mapping performance machines of course, covered well by Greg Banish (for those interested). However much easier to get accurate results with a RR due to repeatability.

I'm guessing the real bonus here is if you have a close map to the car your providing the ECU for to begin with, for example another 8v turbo or Tjet, the buyer should have much less work to do. However I can see the the price of all this creeping up to that of an SA once all the whistles are added.

Still an awesome achievement, maybe you can find a similar Magnetti ecu you can manipulate in realtime?

Last edited:

Being able to flash it does not mean much. You still have to erase the whole 96kb block first and then write it whole in one go. This is not a solution for live mapping. What you do is you keep the map temporarily in RAM and once you are done with it you flash it whole. For that you need lots of it. But I am thinking about circumventing this limitation somehow... :devil:

Being able to flash it does not mean much. You still have to erase the whole 96kb block first and then write it whole in one go. This is not a solution for live mapping. What you do is you keep the map temporarily in RAM and once you are done with it you flash it whole. For that you need lots of it. But I am thinking about circumventing this limitation somehow... :devil:

And the best of luck with that, but you must realise you are nearly at the point where buying a processor, some ram, some drivers and building your own ECU would be a better option. There is only so much you can wring out of this thing, I truly believe you abillities and time would be better spent building the Wojtec ECU.

Edit: Well if you change your mind I want royalties for the name...

Last edited:

A small update. I managed to solder on (pics perhaps later) the two missing coil drivers for the sequential spark, and, after muscling the ECU program a bit, I squeezed the sequential spark out of the thing. Being safety (for the driver and for the engine) critical this needs a bit more testing though. Then the Launch Control is also in place already, and I started working out a diagnostics interface in TunerPro, now it is a bit of tedious work of defining all the data items I want to have in it, but otherwise it is there and works. Idle valve control things also worked out and tested, was not as self-adaptive as I thought, but very clever nevertheless, everything is based on expcted load on idle (judging from system's voltage, air con system pressure, etc.) from which the ICV opening is then derived. Now it is really slowly the time to think on how to live map this thing...

Another video for Mr. Honeymonster visualising the EBC closed loop mode and showing off TunerPro and convincing him it is better than he thinks. The correction kicks in when boost error is below 15kPa either way, otherwise stays 1.0. Boost control itself kicks in at 120kPa of MAP. On the top you can see the DC table for boost, where the current cell is marked (RPM vs. Target boost to DC). It stays fixed in one position, because the RPM and TPS are constant, I was dialing only with the MAP. The diagnostics readouts are also part of TunerPro.

I also have a good idea for fuel semi-auto-tune, only that I would need to feed AFR signal to the ECU. This is not a big problem either, there are 3 free ADC channels for that, but it requires soldering, precise soldering

I also have a good idea for fuel semi-auto-tune, only that I would need to feed AFR signal to the ECU. This is not a big problem either, there are 3 free ADC channels for that, but it requires soldering, precise soldering

Looks impressive Mr. Woj, you don't need to convince me of anything. I am well aware the benefit of Tuner Pro is that it is what you make it. I'm sure you are doing a very good job.

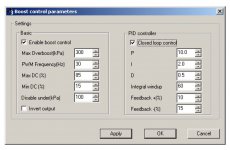

DET 3 uses a very simple PID system that is accurate enough and takes very little time to set up:

This should eliminate the spike still gives you excellent control and all with a very simple little interface. Maybe not as comprehensive but great for the home tuner. A description of PID is in the manual for those interested.

I'm intrigued by how you plan to implement an autotune with out real time mapping? Maybe you are going to use it to write a file that can be flashed after the run based on the results? I guess another option here is your looking to use your PC/memory to hold the real time information and then flash once you've completed? Could work but you'd need a very realiable PC, a BSOD during a tuning session could leave you with a smoldering lump of iron and a fiery mess of an engine.

I wish someone would implement an autotune that could work on torque (with smoothing), unfortunately it would probably require interfacing with a load bearing RR, or atleast telling the computer an accurate constant load condition. It could work with weight I guess but momentum is tricky and you'd need a perfectly flat road. The reality is we should be tuning to torque unless the engine is knock limited. Fueling and knock are unlikely to get you a perfect tune, however they certainly help you get quickly and safely into the ballpark which is a real bonus, and possibly an engine saver for the noob tuner.

DET 3 uses a very simple PID system that is accurate enough and takes very little time to set up:

This should eliminate the spike still gives you excellent control and all with a very simple little interface. Maybe not as comprehensive but great for the home tuner. A description of PID is in the manual for those interested.

I'm intrigued by how you plan to implement an autotune with out real time mapping? Maybe you are going to use it to write a file that can be flashed after the run based on the results? I guess another option here is your looking to use your PC/memory to hold the real time information and then flash once you've completed? Could work but you'd need a very realiable PC, a BSOD during a tuning session could leave you with a smoldering lump of iron and a fiery mess of an engine.

I wish someone would implement an autotune that could work on torque (with smoothing), unfortunately it would probably require interfacing with a load bearing RR, or atleast telling the computer an accurate constant load condition. It could work with weight I guess but momentum is tricky and you'd need a perfectly flat road. The reality is we should be tuning to torque unless the engine is knock limited. Fueling and knock are unlikely to get you a perfect tune, however they certainly help you get quickly and safely into the ballpark which is a real bonus, and possibly an engine saver for the noob tuner.

My boost control setup and PID is practically the same as in DET and EMU. Both in my current ECU and this one here. And the idea for table setup of duty cycles are stolen from MS, in my opinion they got the thing with what they call "initial duty cycles" just right.

For autotune, I was primarily thinking of steady state dynos (or what you call load bearing, but I think the two notions might actually be different, the one I think of does not bear load, but RPM), but could work on the road on statistical basis too. Essentially, this ECU knows the target AFR it is supposed to produce (that is there is a VE table for flat 14.7AFR and an AFR table to get the actual requested AFR), if it can know about the actual AFR it can log things and can calculate what changes are to be made to the VE table. For steady state this is piece of cake, the ECU can tell you what to enter into your file through tuner pro, you save the file and flash it. For road use this is a bit more tricky, there needs to be a procedure to establish if the load is steady enough. On acceleration and vaarying engine loads AFR readings are far from reliable. Another thing is whehter the procedure should correct the fuel at the same time to hit the target AFR, or just measure the difference.

What sucks really bad is the speed of the diagnostics interface. The tranmission overhead is horrible in these modern OBD protocols. The serial connection itself works 30% quicker than in the old IAW-s, the resulting refresh speed is like 5 times lower. On my handheld home brewed tester for IAW 18F I get real realtime data, here I get freeze frames basically

For autotune, I was primarily thinking of steady state dynos (or what you call load bearing, but I think the two notions might actually be different, the one I think of does not bear load, but RPM), but could work on the road on statistical basis too. Essentially, this ECU knows the target AFR it is supposed to produce (that is there is a VE table for flat 14.7AFR and an AFR table to get the actual requested AFR), if it can know about the actual AFR it can log things and can calculate what changes are to be made to the VE table. For steady state this is piece of cake, the ECU can tell you what to enter into your file through tuner pro, you save the file and flash it. For road use this is a bit more tricky, there needs to be a procedure to establish if the load is steady enough. On acceleration and vaarying engine loads AFR readings are far from reliable. Another thing is whehter the procedure should correct the fuel at the same time to hit the target AFR, or just measure the difference.

What sucks really bad is the speed of the diagnostics interface. The tranmission overhead is horrible in these modern OBD protocols. The serial connection itself works 30% quicker than in the old IAW-s, the resulting refresh speed is like 5 times lower. On my handheld home brewed tester for IAW 18F I get real realtime data, here I get freeze frames basically

I'd be talking about a braked rolling road where the operator selects a load then adjusts timing and fuel for the highest speed/RPM for that given load in each RPM range (except the highest ones which would melt your engine if you maintained them too long. These need to be tinkered with on power runs). This is IMO the ultimate base tune prior to be a bit of street/track fine tinkering, torque doesn't lie where as AFR is quite often wrong due to sensor limitations/positions and even peculiar engine designs. AFR should be used as a guide not a complete solution, this is especially true on a turbocharged vehicle. Now this information being streamed in real-time to the ECU allowing it to make adjustments based on torque and simply stay out of dangerous AFR, EGT and knock situations would be a TASTY autotune.

Just to add I think you're talking about a pegged rolling road which maintains the rpm but still measures the torque. This of course achieves the same thing but in a way is better because it allows you to stay firmly in your rpm sites. Regardless the operator normally tunes timing (and the top chaps fueling) for maximum torque then backs of the timing until the torque just starts to drop. The point where the torque just stops rising is obviously the bit we are interested in. As far as I'm aware no autotune works on the same principle. Nearly all work on sensor based inputs from Knock, Lambda, EGT and in some cases cylinder pressure. If you could make an autotune that could tune to torque (in best case torque on the road) you would have the ulitimate plug and play system. This would simply leave the acceleration enrichments, cold start and other minor stuff to set up. If you could do this you'd have the home based tuner chaps breaking down your door for ecu's since you would have almost bypassed the need for a rolling road operator all together.

Anyway, any autotune is better than no autotune.

I hope you can solve the update speed problem.

Anyway, any autotune is better than no autotune.

I hope you can solve the update speed problem.

Similar threads

- Replies

- 16

- Views

- 449