Update on the TWIN EGR system: our camper is running again !!

Finally after 4 weeks, last saturday we could pick up our camper from the garage. The repair on the exhaust system gave the garage quite some trouble. Initially they replaced, with new parts, the High and Low Pressure EGR valves, the MAP sensor, the throttle body, and the EGR cooler. They cleaned the inlet manifold and the DPF, yet there was still an error message. The DPF was sent to a company named Büchli that is specialized in overhauling exhaust systems. They concluded that the DPF was cracked. For this reason the garage placed a new DPF. The overall costs of this repair were about 7000 euro’s which the camperdealer is paying because we still have warranty on the camper.

During the repair process we regularly phoned the garage and discussed the progress. Thanks to the advice I got on this forum I could ask the right questions and discuss the solutions they planned !! Following the advice from

theoneandonly (see earlier in this thread) I also asked them to install a clean copy of the Engine software V32, but this the garage did not consider necessary.

On Saturday I went for a long ride (360 km) on the highway and monitored the performance of the camper using

MES. I used the Template 4 as suggested by

theoneandonly (see earlier in this thread), I only replaced the odometer reading for a vehicle speed reading and added a fuel consumption reading. I also checked several times for any error codes but non showed up.

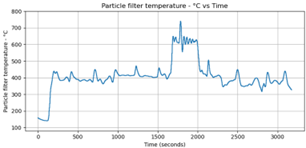

I attached the data for the last part of my test drive in which a regeneration of the DPF took place. During this part of the test drive, I increased the speed from 100 km/h (@2000 rpm) to 110 km/h, and further up to 120 km/h. Below you can see a graph with the temperature behaviour of the DPF during regeneration. Nearly independent of the speed, the temperature of the DPF is about 400 deg C during normal operation. During the regen one can see that the temperature goes up to more than 600 deg C to burn of the soot accumulated in the DPF.

View attachment 466147

The other graph shows the differantial pressure drop across the DPF before and after regen. The pressure drop goes up a little with increasing speed from 100 to 120 km/h, then it peaks at about 1700 seconds where the regen starts. After the regen at about 2000 seconds the pressure drop across the DPF is reduced from about 100-120 mbar down to about 30 mbar.

View attachment 466148

From this graph, I would conclude that the DPF seems to do is its job, it captures the soot and burns it off. Hopefully this will prevent the EGR cooler from getting blocked again.

Analyzing the data further, one can also see that the High and Low Pressure EGR valves actually change position, which was not the case before repair. The High Pressure valve changes most during low speed and the Low Pressure changes most during high speed (100-120km/h). Yet, it is not clear to me how these valves are actually controlled because checking with

MES, I find that they seem to be disabled for position control but enabled for air quantity control.

View attachment 466149

View attachment 466150

QUESTION to the forum: could somebody explain how this air quantity control works ?

Another thing that bothers me a bit is the fuel consumption, I think it is on the high side. Our camper is a Pössl Roadcar 640 based on a Fiat Ducato 2.3, with 130 HP from 2018. It is 6.4 m long and weighs about 2900 kg. It uses about 8 liter/100km @ 90 km/h, which increase to 10 liters/100 km @ 100km/h, and 12.5l/100 km @ 110 km/h.

Question to the forum: what is your opinion about this fuel consumption, is it comparebly high or normal ?

A short note on the legal aspects of this repair.

I consulted a lawyer who told me we have a strong case against the camper dealer in case he would refuse to repair our camper properly and within a certain time limit. In the Netherlands, we have independent of any warranty given by the dealer, a year warranty by law for consumers that buy a product from a company. Apparantly such warranty is not provided when you buy from a private person. Luckily for us the camper dealer did not make any fuss about the repair and followed the advice of the garagist to replace nearly all parts of the exhaust system by new ones.

Regards Bert