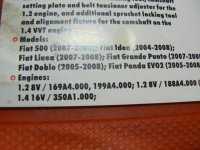

As you probably know I did both our (60 hp) panda and my boy's 1.4 VVT Punto by the tippex method and then followed up by checking their timing was correct by installing the timing tools just to be sure, so I know it works.

Here's a wee observation/thought concerning a possible advantage of doing this by the Tippex method.

Shortly after we'd bought the Panda and then with my boy buying the Punto and realizing both cars would be the best of having their belts renewed gave me the excuse I needed to justify buying my own copy of

MES because I had discovered, from posts I'd read on the forum, that I was likely to need to do a Phonic Wheel Relearn/Reset after I'd changed the cambelts.

However neither have had any problems, have run perfectly, posted no codes and required no resets. (So I didn't need to have bought

MES at that moment. However I consider it to be one of the most useful aids to maintaining our Fiats that I've so far bought) I've pondered over this, the Phonic Wheel "thing", at some length and I've come to this conclusion:-

The whole problem revolves around the way the ECU "sees" the relationship between the crankshaft and camshaft sensors. If you follow the "recommended/official" way of doing the job then you will slacken the big Hex/Torx bolt on the cam sprocket thus allowing the sprocket to "float" on the end of the cam. Then, having fitted the new tensioner and belt, maybe water pump too, applied tension to the belt and with the crank and cam locked up in the correct positions you would tighten the cam sprocket bolt thus locking the sprocket to the cam. Job done, just the guards, engine mount etc to reassemble.

So why do some people end up with the check engine light on? - usually after the car has had a wee run out on a dual carriageway or just a run in the country, somewhere where the engine is run at higher RPM for a wee while - My theory is that when the cam sprocket is slackened, no matter how careful you are, I doubt if it will be in absolutely exactly the same position when that bolt is retightened - I've noticed there is a wee bit of backlash in the cam locking tool and also there must be a small clearance in the bolts which hold the crank locking tool. There's also always the possibility of a very small movement taking place whilst you are tightening the cam sprocket bolt itself as you must not do this with the cam locking tool in place to avoid potentially damaging the end of the cam - Now when the engine runs the ECU notices that the signals from the crank and cam sensors are no longer arriving with exactly the same time interval between them and fires up the CEL. Performing a Phonic Wheel Relearn "tells" the ECU that this is the new norm and not to "worry" about it, so the light doesn't illuminate any more.

If you change the belt using the tippex method you totally eliminate the possibility of introducing these variables - I believe the belts are produced to such close tolerances that differences introduced by using different makes of belt are inconsequential - So the sensor signals will be seen by the ECU as exactly the same as they were before. The only caveat I'd place on this is that the first time you do an "unfamiliar" engine you need to check the timing of cam to crank by installing the timing tools before you strip the old belt off to be sure someone before you hasn't timed it up incorrectly and, as you will have had to remove the cam cover to do this, you might as well confirm the timing is correct by reinstalling the timing tools when you've finished just to double check the timing is still spot on. Once you've done your engine this way and know the timing to be correct, from then on you can just do belt changes by the tippex method without needing to remove the cam cover which means you only need access to the belt end of the engine so considerably quicker and easier to do.

Supporting evidence would seem to come from inquiries I've made at local garages. The main agent service department tells me they do the belts the "official" way, using the official tools and always do a Phonic wheel relearn. I learned this when I challenged them over the considerably greater price they quoted for the job when I inquired. The wee local garages all seem to do it by the tippex method and apart from my favorite wee Fiat Indy non of them perform the relearn and report no subsequent problems. Indeed they probably don't have diagnostic gear that could do the relearn anyway.