Ok I understand.

I need to extend the lead to the OBD and run it through the cabin of the car, avoiding the HT leads and coils. I will try that.

It's more work than you think, but it also depends on how your car is stripped at the moment.

Finally, I am interested in which aftermarket ECU you would choose because the only reason for having the car is for motorsport purposes. You are right that I would probably end up having someone do all the work.

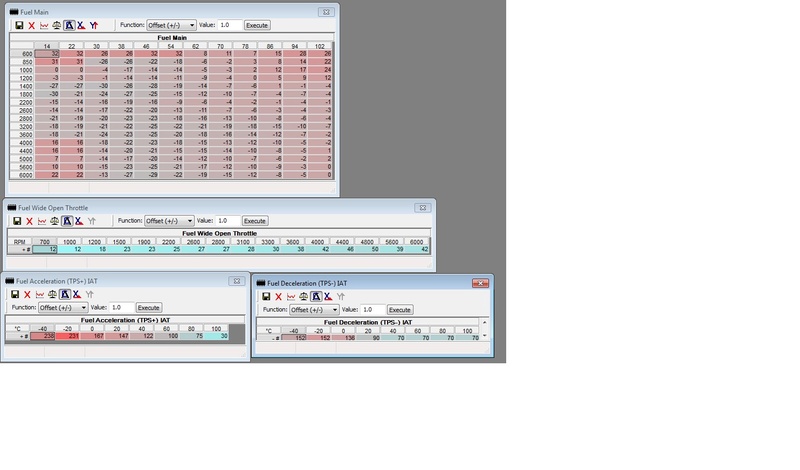

Personally I would not go for an aftermarket ECU, not even for a turbo application, I am crazy about playing with factory ECUs, but that's me. But apart from that, I'd suggest looking into ECU Master's EMU for a reasonably priced one, especially that this one (maybe others too) include some sport options (like launch control). But you have to do your homework here in terms of what you want, need, your budget, and the work required on the car. Setting up a standalone system is a bitch, you have to do all the wiring and set up the software practically from scratch. Done by oneself it takes a long time and lots of swearing, done by a specialist costs a small fortune.

Alternatively you can go for a good quality piggy back system like DET3 (also from ECU Master). Less wiring work, and very decent tuning options. And less work setting up software as you start from a running factory ECU and do your work on top of that.