I'm thinking I'm seeing a round filler in top right of picture ....

@koalar great question re-oil filler type... could the change from square to round oil filler cap correspond with change in belt ?

Cheers

Jack

Went from square rubber to round plastic long before 2009 didn't it?

Look on a specialist site..

Try shop4parts.

VIN plate numbers may be informative... It's in the boot

Better still, give them a ring for advice. They are very knowledgeable people and not at all pushy. Have freely given me valued advice in the past. I suppose the thing is that if it was running well without any reason to doubt it on the existing belt, then it's probably the right one?

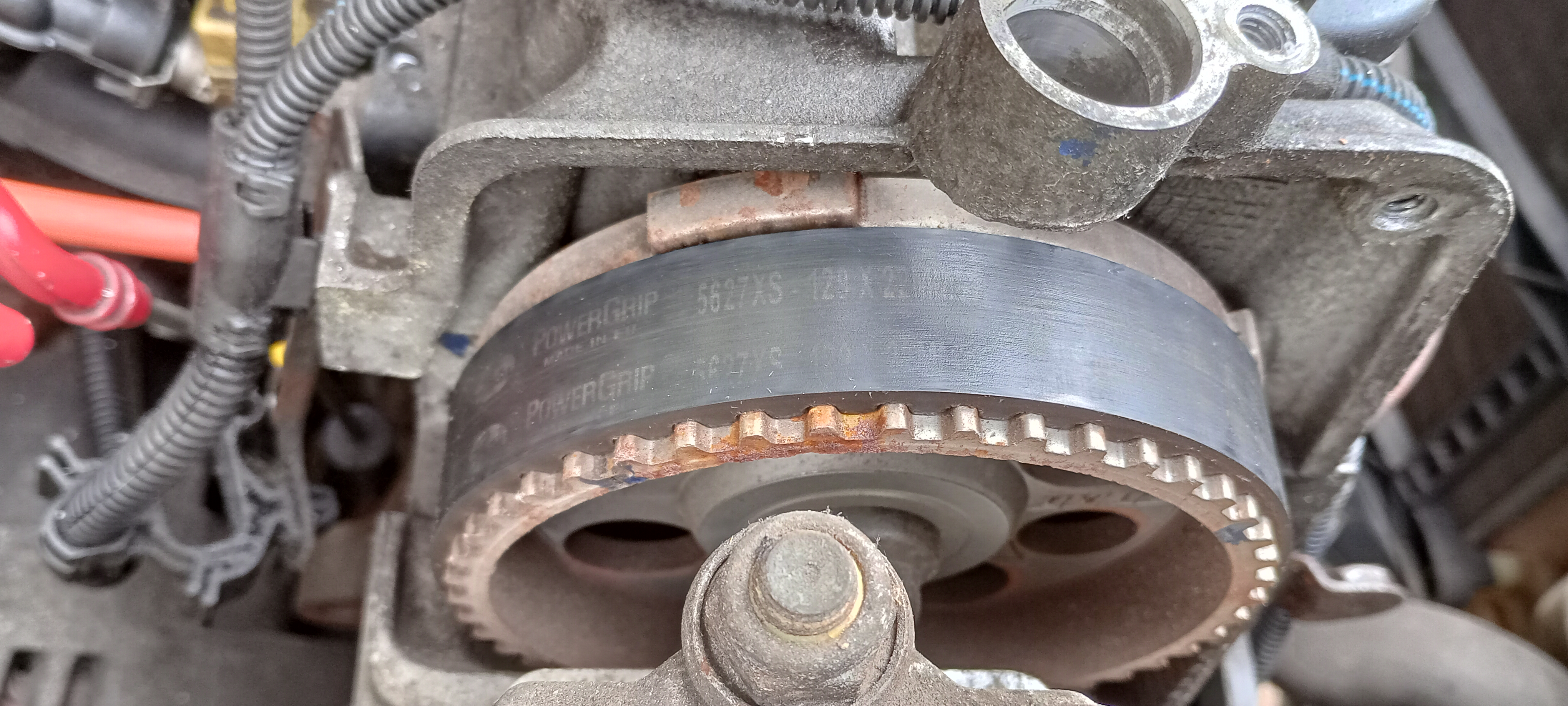

My first thought looking at your photo is the belt groove profile does not fit the pulley teeth correctly - but hard to tell from photos sometimes

Ah, you noticed that too? - Tooth profile I mean. This aspect and belt materials and construction in general interest me very much. I've looked at lots of belts and how they mesh with the pulley teeth over the years and often noticed that, on a belt that's "done it's time", there's a bit of clearance, only a wee bit mind you, between the side of the belt tooth and the pulley tooth on the "trailing side" of the tooth. I think this is just due to normal compaction and wear of the belt material when it ages. Tooth pitch doesn't seem to alter.

Think back a few years, well maybe more than a few? and square tooth profiles which exactly matched the pulley teeth were common. Now a rounded profile seems to be in favour? Here's a selection of belts I've done over the last few years, on the "Family Fleet", so not just Fiats.

They're pretty much all rounded profile:

But hang on a wee minute. Look at the two belts at the bottom:

Unlike all the others they have a wee "slot?" running along the top of their teeth which the others don't. I'll comer back to them in a minute.

I'm interested enough in this that I've had several email conversations with manufacturers about belts in general and tooth profile in particular. I've always found Gates very helpful in the past so I wasn't surprised that they engaged quite openly with me. It appears that, of course, the tooth pitch is very important but the actual shape of the tooth is less so because the drive is transmitted through the base of the tooth where it meets the main part of the belt. This is why any cracking observed at the base of the teeth is very important and indicates an immediate renewal of the belt is required.

Surprisingly, although I'm sure it's important, the profile of the tooth seems less critical. I've noticed that most of the genuine Fiat belts I've removed have that wee slot I talked about above. Here's an old one from my '99 Panda Parade:

which you can see has the slots. and here's the ones I took off the Panda and Punto a couple of years ago:

Both are original fitment genuine Fiat belts and you'll have seen right away that one has the slots and the other doesn't - identical belts in all other respects complete with their Fiat/Alfa/Lancia logos. I replaced both with the recommended Gates belt kits where the belts had rounded teeth with no slots.

Some time after that I had a conversation with the Gates people about the slots because I wondered if the slots had something to do with allowing the teeth to flex more freely as the belt bends and straightens. The answer I got was to do with copyright and ownership of the tooth profile design rather than a physical difference in performance of the tooth design. I had wondered also whether it was something to do with belt noise where the belt was meshing with the pulley teeth when running, but I've noticed no difference. The belt with the slots was from the Panda and it was making a small amount of noise from where the belt meshes with the cam pulley teeth before the new belt was fitted which is unchanged with the new Gates belt which doesn't have the slots. At the end of the day Fiat won't be actually manufacturing their own belts so I think the tooth profile will depend on the actual manufacturer of the belt - got a slight suspicion that the slotted design "belongs" to Continental, but can't really tell you why I think this.

I'm interested also in the materials used and whether it's incorporated into production thus allowing newer versions of the belts to be longer living. For instance Dayco seems to make a big thing about the tooth facing material on their belts.

https://www.ymfcarparts.co.uk/blog/dayco-white-belt-timing-belt-kits/ - some sort of PTFE I think? You can see here that it's white on this belt from my Ibiza:

I didn't actually do the belt replacement on this one myself but I did ask the garage to make sure it was replaced with an identical belt and I doubt if I'll still have the car when it's due it's next one.

By the way, don't just throw away all the old belts. They are phenomenally strong and can be used for battery hold down straps etc. I've got one securing my jump start battery to a wooden base:

which makes it a bit less liable to tipping over when being transported in the car and makes it easier for me to secure it to the lugs in the boot with bungees. I've also used them with the farm jack to pull "stuff" - they don't stretch at all.