stuartbat

New member

Okay guys going to be doing my head gasket on my mk 1 sporting 1.2 16v. (burning oil and water and never getting hot, oil leaking at back of engine )

What i want to know is there a how 2 for the 16v engine?

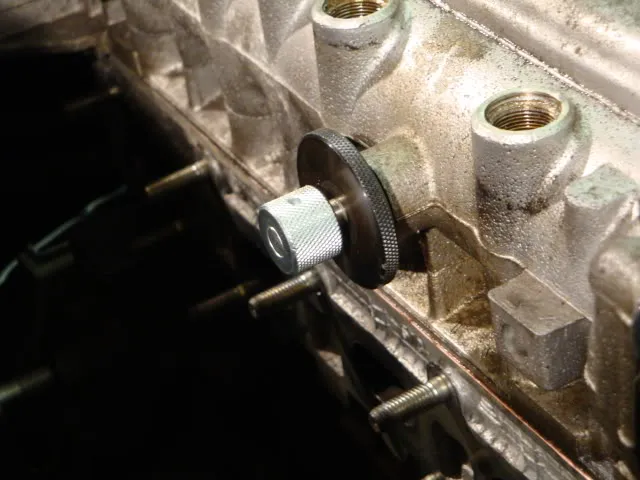

Also do i really need all the special tools? Or can i do without them by marking up the head and crank.

I am not a noob when it comes to playing with cars recently did a head gasket on a 1.0L 12v corsa

What is the head tightening sequence and what should they be torqued up to and then turned a further what degres?

Thanks in advance guys

stuart

What i want to know is there a how 2 for the 16v engine?

Also do i really need all the special tools? Or can i do without them by marking up the head and crank.

I am not a noob when it comes to playing with cars recently did a head gasket on a 1.0L 12v corsa

What is the head tightening sequence and what should they be torqued up to and then turned a further what degres?

Thanks in advance guys

stuart