Sorry for the late addition to this post. I know that you decided not to remove yours Tony, but if I can add to this thread for folks that may be facing this in the future:

First, Sean mentioned how he removed the seal in a concurrent thread:

https://www.fiatforum.com/500-classic/345169-franko-1971-500l-18.html?p=4028356

I was able to knock the seal housing off of the gearbox from the inside as Peter mentioned but it took some doing as RTV or similar product had been used to seal between the two.

I read elsewhere that rather than remove the seal from the housing, it's easier to just replace the whole unit (housing, seal, and bushing). But, I had the bushing and seal in hand...

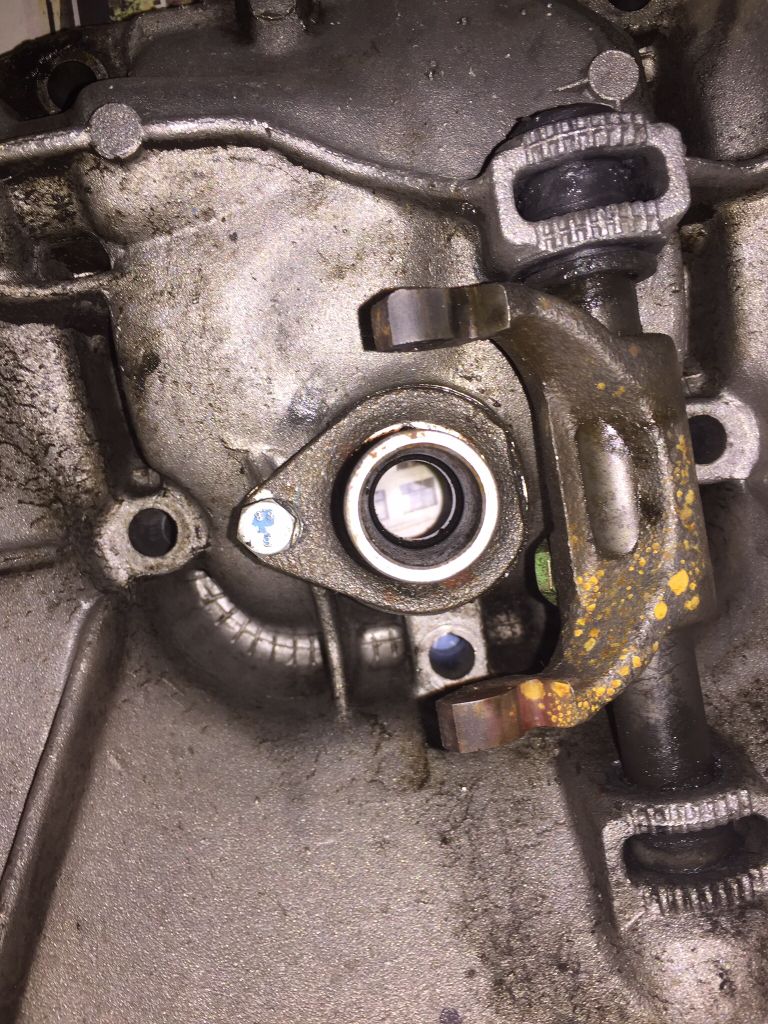

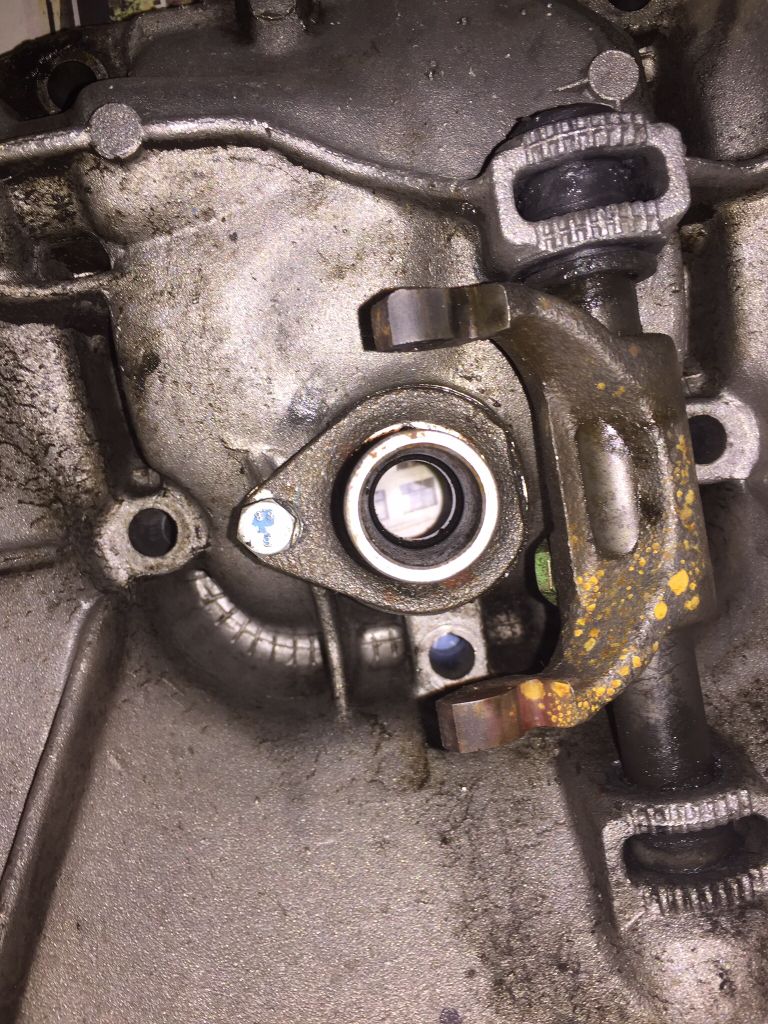

Similar to Sean, I was able to just knock the bushing out with a drift pin but struggled with the seal. In the first photo, the metal ring of the oil seal sits down against a flange in the bushing. I tried to use a small drift pin inserted in hole highlighted in red to push the seal out from the other side (Second photo). But, the seal was in solid and the edge of the metal ring just bent. Unfortunately, the hole doesn't line up with the outer edge of the seal either so, when pounding on it, the metal ring just bends. But, by bending it, it created a void between the metal ring and the housing that I was able to get an "L" shaped hook in between the two and by simply prying in the four quadrants of the seal, I was able to get it out fairly easily. In the first photo, the metal ring of the old seal in on the right-hand side of the photo. This is what you're up against.