Ok so I have reached the point of fitting a new front spring to Arancia.

I’ve seen clever people make the appropriate tool to put tension in it before fitting- the safest way judging by the energy locked up in the spring itself!

Does anyone have a way of fitting it without the special tool? It all looks rather dangerous if it’s not held in place properly !

Many thanks for your thoughts.

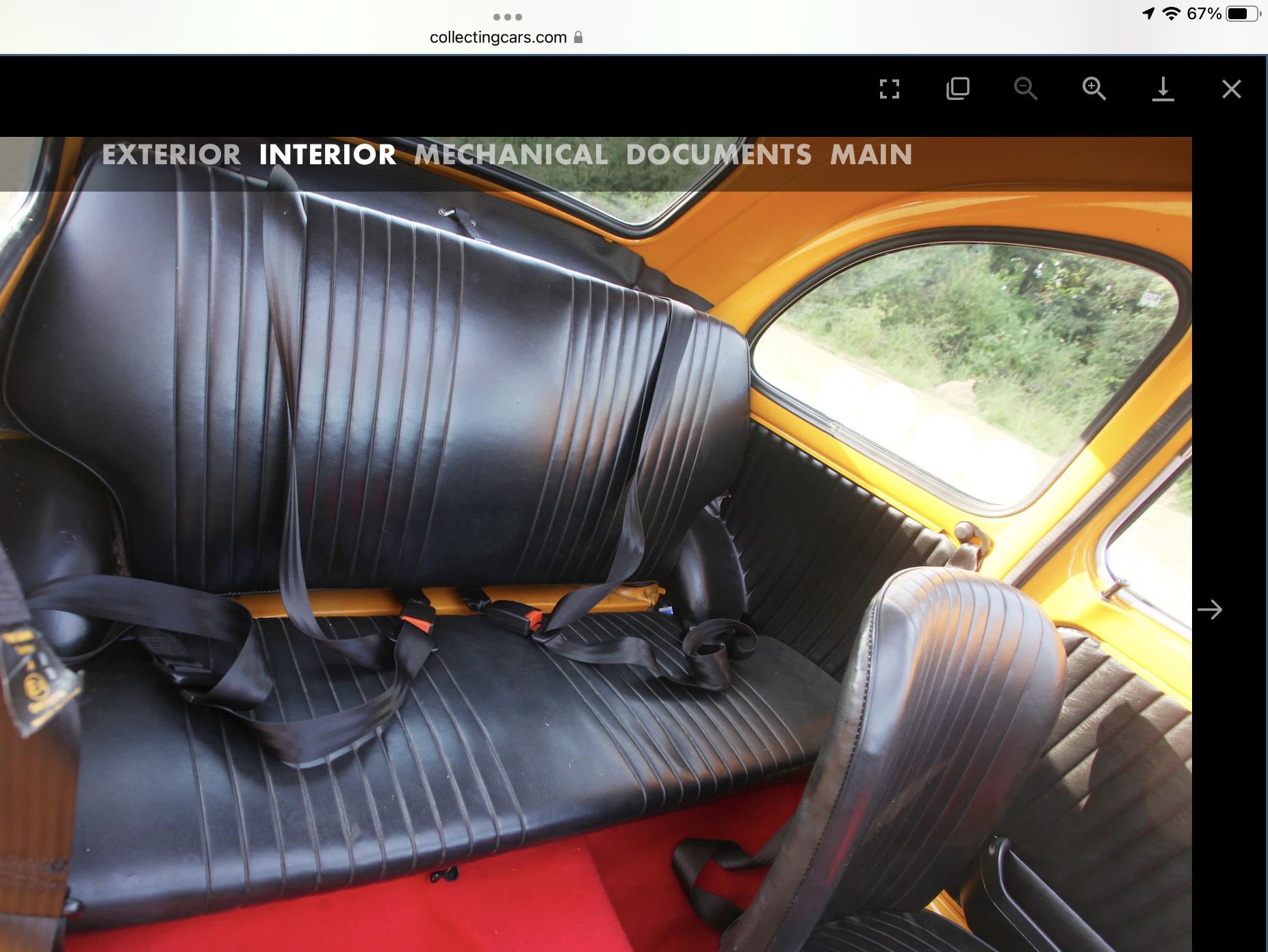

While I’m here a photo or two…. It’s all going at a suitably glacial pace!

I’ve seen clever people make the appropriate tool to put tension in it before fitting- the safest way judging by the energy locked up in the spring itself!

Does anyone have a way of fitting it without the special tool? It all looks rather dangerous if it’s not held in place properly !

Many thanks for your thoughts.

While I’m here a photo or two…. It’s all going at a suitably glacial pace!