My 1968 Fiat 500L never had seatbelts. It is sooo weird driving a vehicle w/o seatbelts (even though the safety device in this vehicle would only serve to assist investigators to locate body parts).

The factory built the vehicle w/ standard 7/16-20 reinforced female threads for three point seatbelts, w/ a pair on the floor behind the front seats, plus one on the side door latch wall, under the window, on both sides of the vehicle. These factory mounting points are designed for loose seatbelts, w/o retractor mechanisms. On my vehicle those existing floor mounting points were covered w/ glued plastic caps, under the carpeting.

Like many other owners, I wanted to add seatbelts w/ retractors, instead of loose seatbelts.

To that end I selected these dual sensitive 3-point seatbelts w/ 12" cable end because I preferred the appearance of the retractor mechanism, over this standard 3-point retractor seatbelt. I didn't like the appearance of that small side cylindrical addition on the standard retractor, as compared to the plain appearance of the dual sensitive retractor. I also purchased two sets of these mounting hardware. If I didn't already have these on-hand, I would have also purchased four of these bolt head caps, for the exposed bolt heads on the floor, even though those are covered by the floor mats on my vehicle. The bolt heads are already concealed on the retractor and on the door jamb, not requiring covers at those locations.

Note I needed to have the manufacturer shorten these seatbelts by 36", as they arrived waaay too long for this teeny vehicle and wouldn't fully retract into the mechanism, leaving a floppy mess. Now they work fine.

The difference w/ the dual sensitive retractor is that it will lock when not vertical, such as if the vehicle is in a roll over accident.

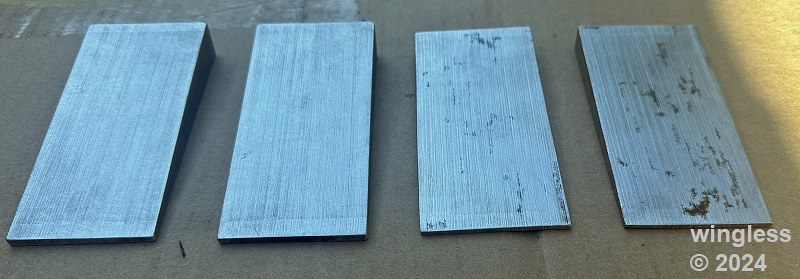

WRT to the application in the Fiat 500L, the mounting surface is not vertical, inhibiting the proper operation of that dual sensitive mechanism. My solution was to purchase two pairs (four pieces) of these 2" wide 4.7" long steel wedges to mount between the body and the retractor so the normal orientation of that retractor is vertical.

Those wedges arrive ROUGH, w/ sharp metal burrs, surface rust and sharp edges. My solution was to file and sand the parts, then prime and paint the parts. Then a mounting hole was drilled in the bottom corner, to permit the standard 7/16-20 seatbelt mounting bolt to pass through. Note that the hole is not centered, making the offset hole on opposite sides for the driver's side and the passenger side.

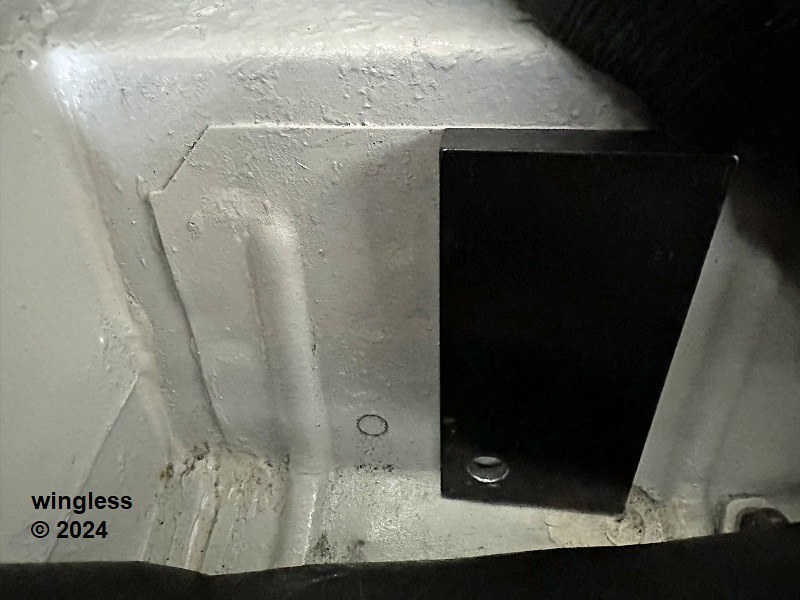

The top edge of those wedges are secured w/ this 3M 5925 VHB Acrylic Tape. That is excellent stuff and I've used it lots.

One REALLY nice thing about this mounting location is that it also passes through the additional steel that holds the rear suspension, making that new mounting location reinforced and as-such appropriate for mounting the seatbelt. That location also fits great w/ the existing curved vertical reinforcement rib.

Note I needed to additionally purchase a pair of 7/16-20 x 2" Grade 8 bolts for attaching the retractor to the vehicle, because of also passing through the wedges as the existing hardware wasn't long enough. Easy enough from the local hardware store.

An awl is used for locating the place to trim the carpeting and the padding by poking through from the bottom.

The 12" cable end for the buckle receptacle is formed into shape prior to attaching to the vehicle.

The finished visual appearance is VERY acceptable to me.

[/url]

[/url]

The factory built the vehicle w/ standard 7/16-20 reinforced female threads for three point seatbelts, w/ a pair on the floor behind the front seats, plus one on the side door latch wall, under the window, on both sides of the vehicle. These factory mounting points are designed for loose seatbelts, w/o retractor mechanisms. On my vehicle those existing floor mounting points were covered w/ glued plastic caps, under the carpeting.

Like many other owners, I wanted to add seatbelts w/ retractors, instead of loose seatbelts.

To that end I selected these dual sensitive 3-point seatbelts w/ 12" cable end because I preferred the appearance of the retractor mechanism, over this standard 3-point retractor seatbelt. I didn't like the appearance of that small side cylindrical addition on the standard retractor, as compared to the plain appearance of the dual sensitive retractor. I also purchased two sets of these mounting hardware. If I didn't already have these on-hand, I would have also purchased four of these bolt head caps, for the exposed bolt heads on the floor, even though those are covered by the floor mats on my vehicle. The bolt heads are already concealed on the retractor and on the door jamb, not requiring covers at those locations.

Note I needed to have the manufacturer shorten these seatbelts by 36", as they arrived waaay too long for this teeny vehicle and wouldn't fully retract into the mechanism, leaving a floppy mess. Now they work fine.

The difference w/ the dual sensitive retractor is that it will lock when not vertical, such as if the vehicle is in a roll over accident.

WRT to the application in the Fiat 500L, the mounting surface is not vertical, inhibiting the proper operation of that dual sensitive mechanism. My solution was to purchase two pairs (four pieces) of these 2" wide 4.7" long steel wedges to mount between the body and the retractor so the normal orientation of that retractor is vertical.

Those wedges arrive ROUGH, w/ sharp metal burrs, surface rust and sharp edges. My solution was to file and sand the parts, then prime and paint the parts. Then a mounting hole was drilled in the bottom corner, to permit the standard 7/16-20 seatbelt mounting bolt to pass through. Note that the hole is not centered, making the offset hole on opposite sides for the driver's side and the passenger side.

The top edge of those wedges are secured w/ this 3M 5925 VHB Acrylic Tape. That is excellent stuff and I've used it lots.

One REALLY nice thing about this mounting location is that it also passes through the additional steel that holds the rear suspension, making that new mounting location reinforced and as-such appropriate for mounting the seatbelt. That location also fits great w/ the existing curved vertical reinforcement rib.

Note I needed to additionally purchase a pair of 7/16-20 x 2" Grade 8 bolts for attaching the retractor to the vehicle, because of also passing through the wedges as the existing hardware wasn't long enough. Easy enough from the local hardware store.

An awl is used for locating the place to trim the carpeting and the padding by poking through from the bottom.

The 12" cable end for the buckle receptacle is formed into shape prior to attaching to the vehicle.

The finished visual appearance is VERY acceptable to me.