Hi Folks.... Got a Panda (169) 1.2 2010. I replaced slipping clutch about 4 years ago, it was the cheapest ebay had to offer and though it was centred it never felt like it was. It's had a waring noise ever since. Anyway to the present my Mrs tells me the clutch doesn't feel right again and sure enough when I drove it, everything above 2000rpm slipping. I also noticed oil around bottom of clutch housing. Immediate thoughts before taking out clutch and g/box was either the crankshaft rear seal or input shaft seal. Have taken the g/box/clutch housing out of the car and started to strip g/box, can see the input bearing is shot and was surprised to see the original bearing had a nylon/plastic cage which was in pieces. Original bearing is a 6204 (20x47x14mm) not sure what brand but definitely knackered and not even sure how many balls were in it to begin with, so not sure if balls missing or just cage collapsed. I have seen a couple of videos on Y/tube but they were in Italian but I did notice they had upgraded the bearing to a cylindrical roller bearing but not sure which type they used. Some of those have lips others don't etc and then some have double lip on outer race and single lip on inner and vice versa. I am leaning towards a NF204 which has the double lip on the inner race but then not sure which way round to place it in the housing ? Anyone done this ? Or just get a regular 6204 deep groove bearing with a steel rather than plastic cage ? I do know some have put sealed bearings in the fiat 500 but then the oil seal dries out too and then another problem ? Any advice welcome. Thanks in advance.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Technical Another G/Box Input Shaft Bearing Thread !

- Thread starter CLUTCH

- Start date

Currently reading:

Technical Another G/Box Input Shaft Bearing Thread !

5 speed gearbox

The original has 7 ball bearings with a glass reinforced polyamide (plastic) cage no seals

Very expensive

6204.A.G15J30

Plenty have fitted standard bearings

SKF Explorer 6204 C3 for example

Please note the bearing does not go tight against the gear there is a small gap, Fiat use a special tool, but can be done with feeler guages or suitable spacer

6 speed in higher power cars have roller bearings not need in the 1.2 and 1.2

Sounds like the bearings run dry and/or over heated. In good clean oil they are good for over 200K miles

The original has 7 ball bearings with a glass reinforced polyamide (plastic) cage no seals

Very expensive

6204.A.G15J30

Plenty have fitted standard bearings

SKF Explorer 6204 C3 for example

Please note the bearing does not go tight against the gear there is a small gap, Fiat use a special tool, but can be done with feeler guages or suitable spacer

6 speed in higher power cars have roller bearings not need in the 1.2 and 1.2

Sounds like the bearings run dry and/or over heated. In good clean oil they are good for over 200K miles

Last edited:

Thanks mate. It seems to be the cage is the design weakness, it can't take the radial load. Do you know if anyone has tried a cylindrical roller bearing of the same dimensions as they can handle larger radial load ? But I'm not sure if they would be up to the axial load ? I found the bearing you mentioned on ebay for £6 but not confident in that set up and from my research i seems to be a well know problem. Not sure if the original was a cost saving exercise or a deliberate weak link for that to fail rather than a greater catastrophic failure. Decisions ..... decisions.... still thinking of a roller bearing as don't want to be messing with this box again......famous last words & bagernomics !!The original has 7 ball bearings with a glass reinforced polyamide (plastic) cage no seals

Very expensive

6204.A.G15J30

Plenty have fitted standard bearings

Yes it can, the same gearbox was fitted to turbo cars that had 3x the torque of the 1.2 VVT and some of which were modified to over 4x the torqueThanks mate. It seems to be the cage is the design weakness, it can't take the radial load.

£6 Is new old stock surplus, somebody in Germany has a shed load of then. Been selling them on eBay for several yearsDo you know if anyone has tried a cylindrical roller bearing of the same dimensions as they can handle larger radial load ? But I'm not sure if they would be up to the axial load ? I found the bearing you mentioned on ebay for £6 but not confident in that set up and from my research i seems to be a well know problem.

Watch the shipping cost, now we aren't in the EU

Not sure if the original was a cost saving

Buy the bearing new, They are very specialized. They have a reinforcing ring in one side. They are about $35 last I looked., compared $4 for the bearing used elsewhere in the gearbox

I don't know why they havr chosen this bearing,exercise or a deliberate weak link for that to fail rather than a greater catastrophic failure. Decisions ..... decisions.... still thinking of a roller bearing as don't want to be messing with this box again......famous last words & bagernomics !!

The oil flow to the bearing has been improved on latter gearboxes, I beleive but haven take an early box apart

But there must be a reason why they spend more, especially when you are producing tens of millions of these boxes

It's up to you what you fit., Any bearing that's dimensionally the same, allows the same oil flow and C3 will probably do

I have taken 2 panda gearboxes apart and 1 fiat 500, the input shaft bearing has run dry in all of them,

Which failed first i don't know, oil seal then bearing, bearing then oil seal.

But my last 2 pandas did nearly 400K miles between them on the original bearings

Just to give some more context for those that have yet to experience this problem.

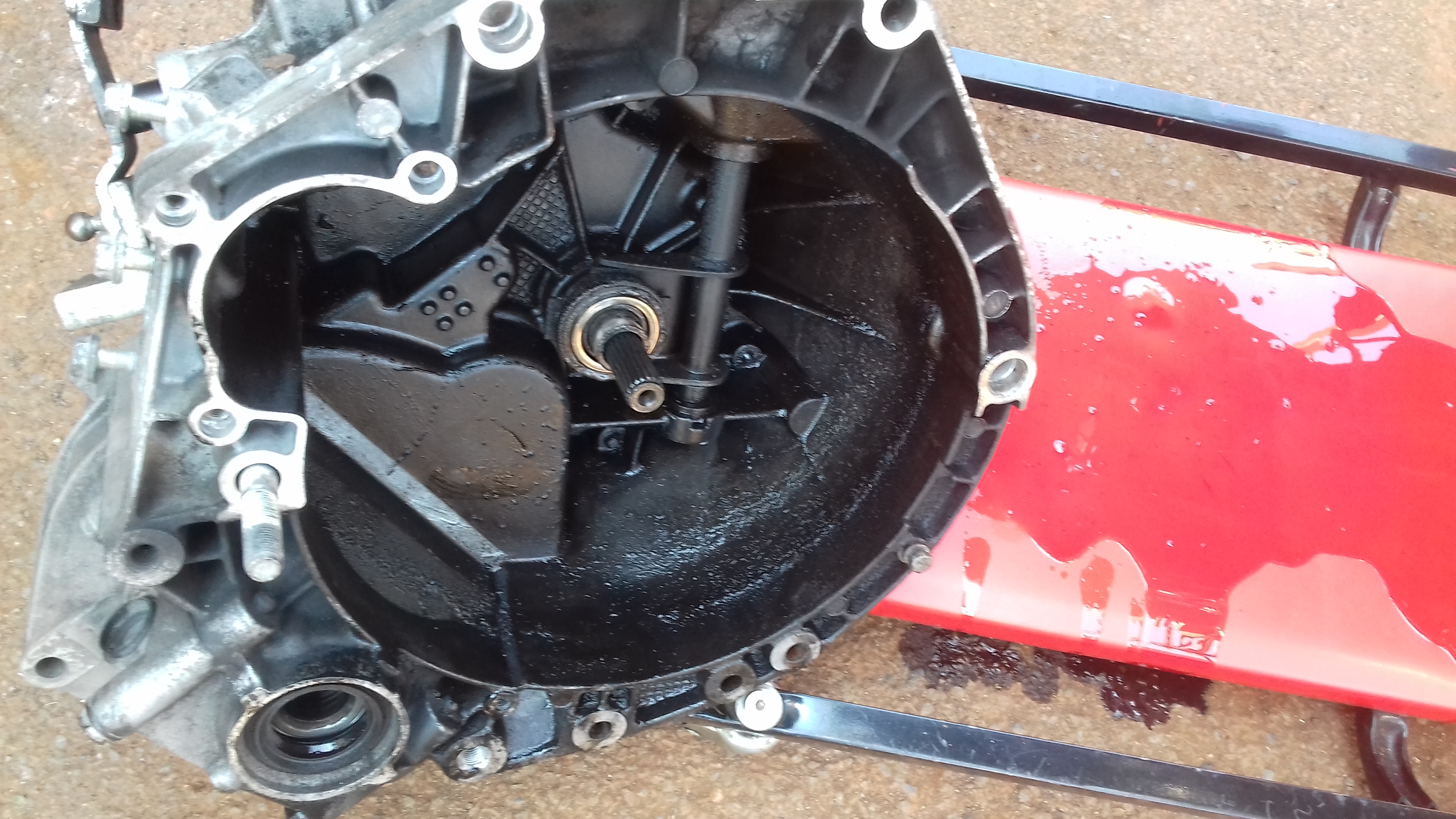

1) Clutch slipping above 2000 rpm (surprised any bite at all when I saw how much oil in clutch housing and on clutch itself.

2) Evidence of drips at bottom of clutch housing.

3) gearbox and cutch housing removed and inspection.

The sound isn't the throw bearing or fork, it is the shaft knocking.

Last time I did the clutch I don't recall seeing this crack like mark and maybe I notice now as the oil covering makes it stand out ? So with the amount of oil I now don't know if it is down to a crack in the rear of the crown gear space ? There also looks like welding spatter, so then I start to suspect perhaps they are just casting marks ?

And notice there are other crack like lines around the housing which weren't so visible when I did clutch 4 years ago. Anyway I still don't know for sure and will have to hope it is just the seal and bearing and keep an eye on things once it boxed up again.

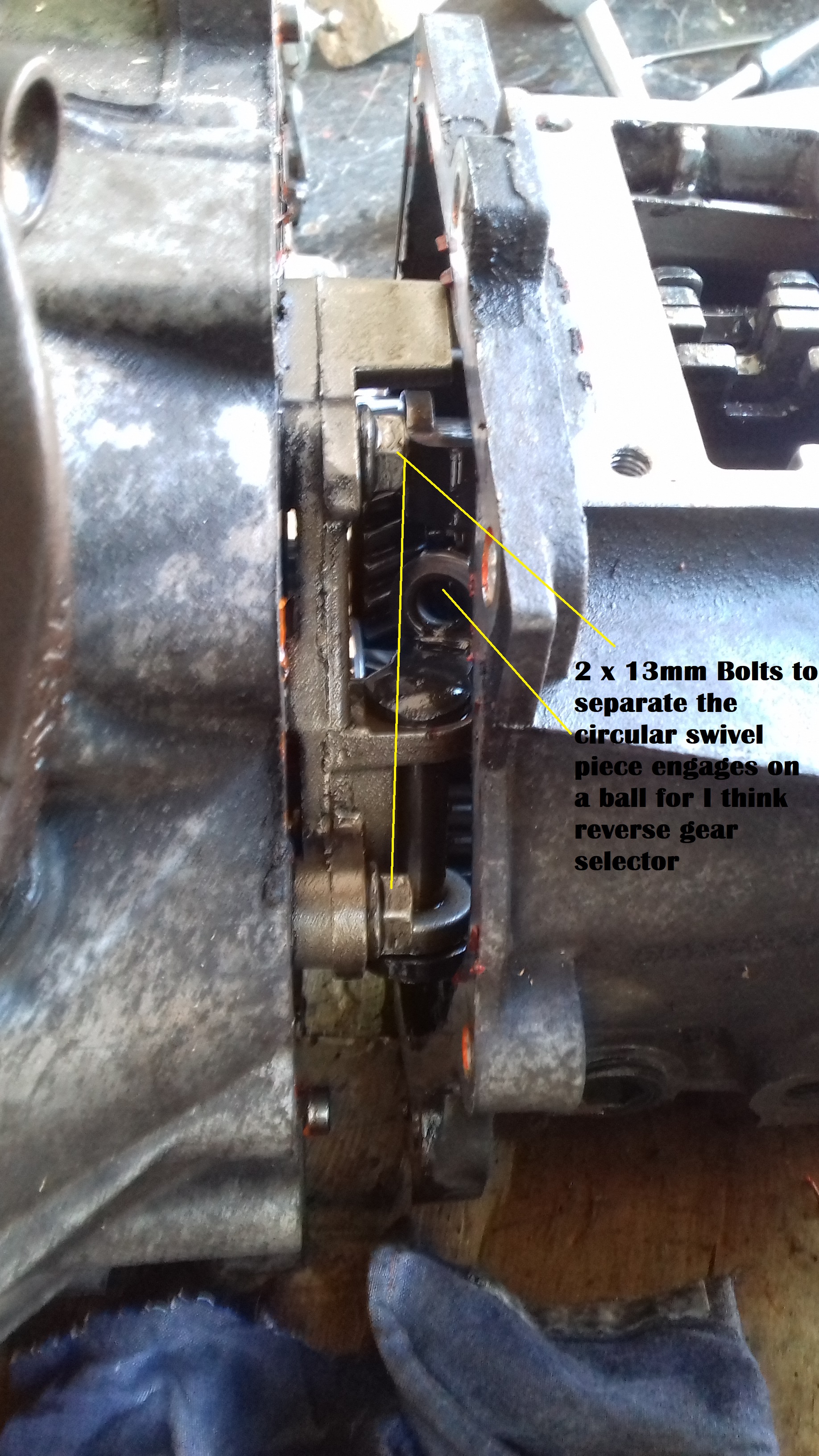

5) Next step I wanted to see if could separate g/box from clutch housing and remove bearing and seal without taking gears out. Once separated and waggling apart slightly I found 2 x 13mm bolts which prevent it from coming free so removed those and then saw part of collapsed cage and at that point didn't know if a ball was missing as didn't know how many in the original bearing.

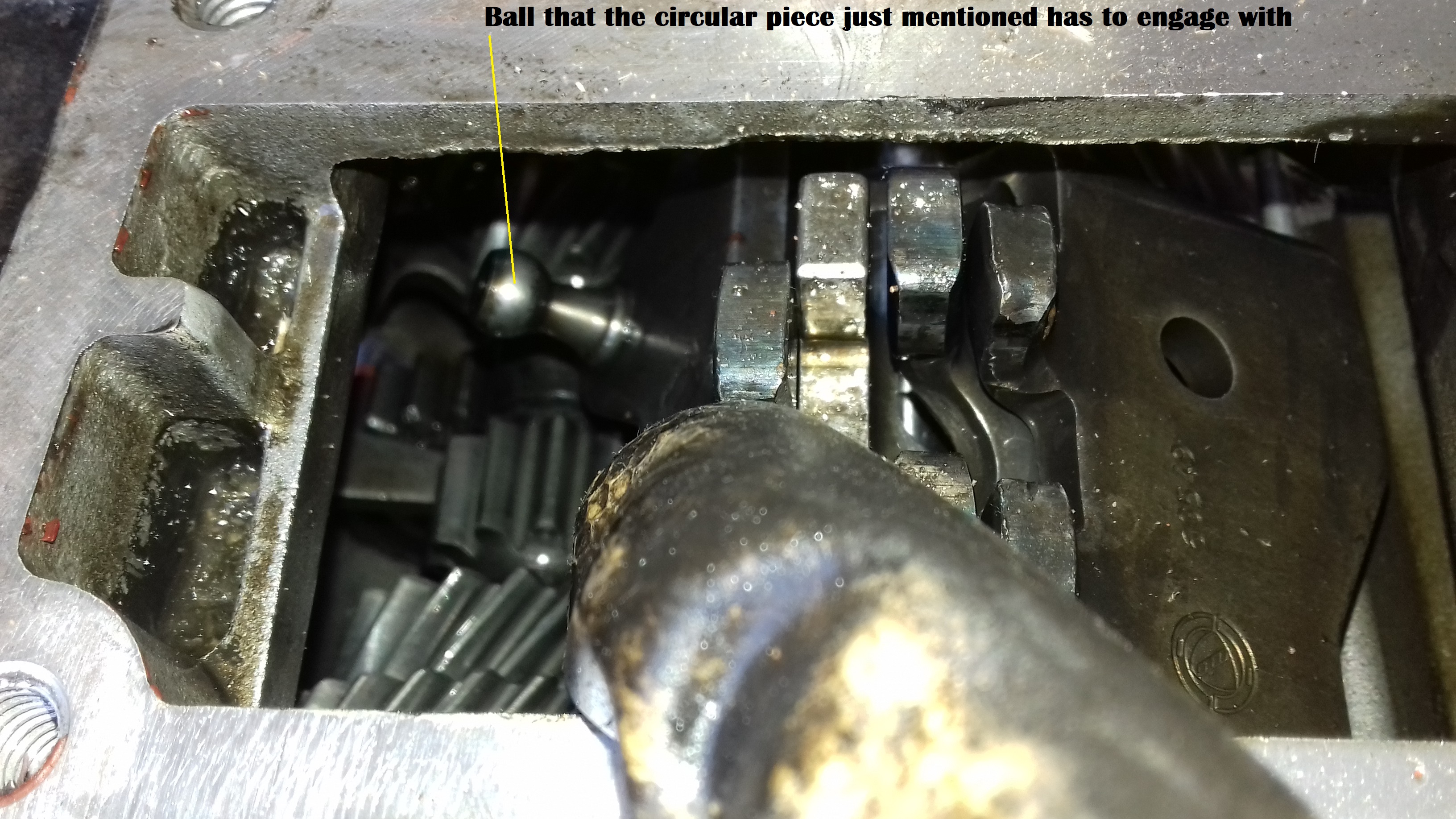

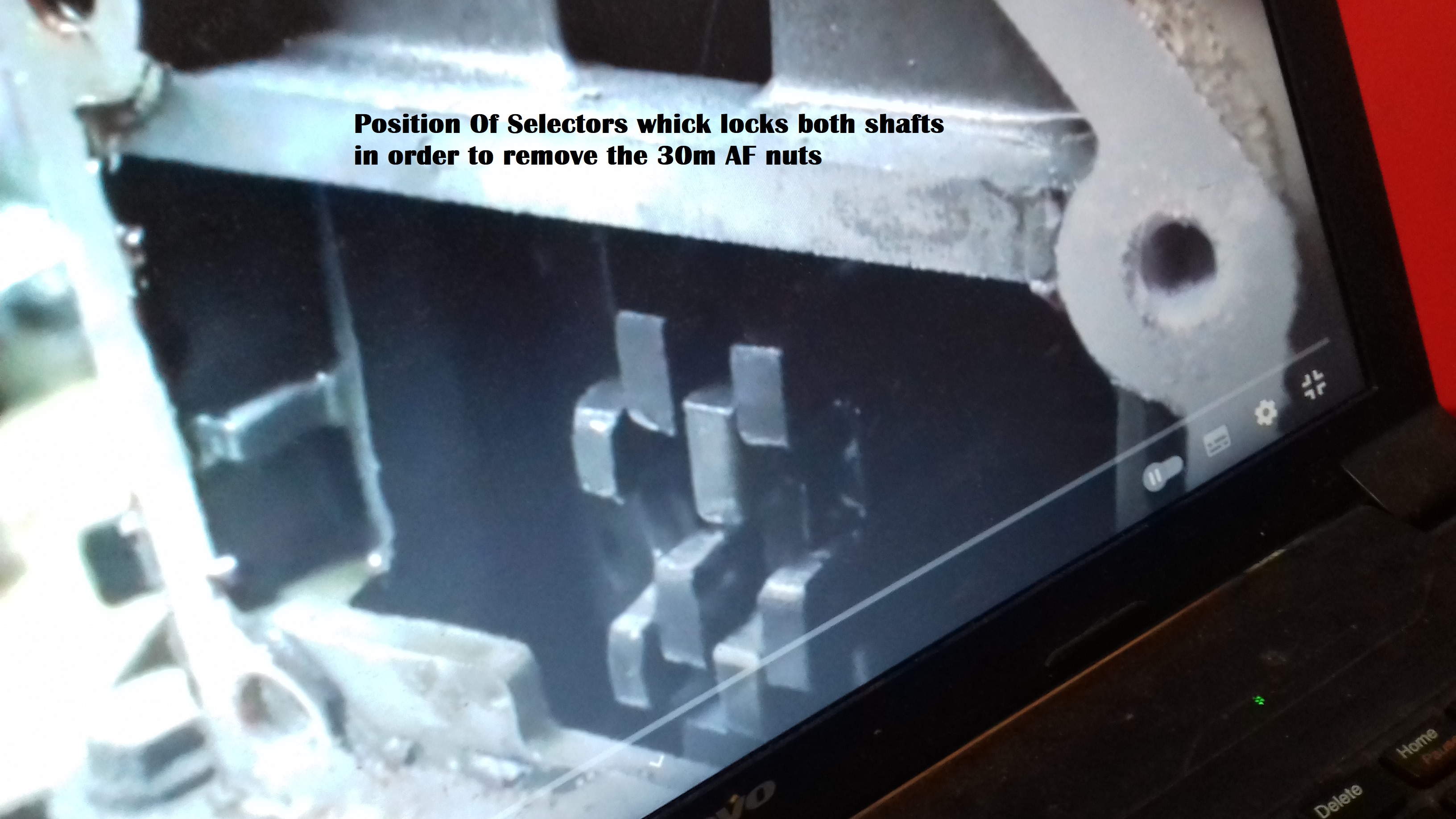

6) It was at this point I thought best to strip down and clear out any bits from the diff and the g/box itself so removed the g/box end cover and quickly discovered if you decide to strip it would have been easier not to remove the already removed 2 x 13mm bolts because I could not remove the large 30mm pinion nuts. So I put the 2x13mm bolts back in, hooked up to the ball and fixed the g/box case back to the clutch housing with just a couple of bolts, it was then rigid enough to move selectors as shown which locked the shafts and then enable me to remove the 2 x 30mm nuts. Had to ratchet strap the g/box down to a table to get enough grip to loosen the big nuts.

T

This pic was provided by my brother, to show position of selectors required to lock shafts, courtesy of the internet some place.

7) After removing the large nuts, remove the bolt from the fork and then everything above the plate with the Alen bolts in will just pry off easy enough. Then remove the countersunk Alen bolts and that plate. This then reveals the end bearings on both shafts which are held in place by large circlip. Following the removal of those go back to step 5 and separate the g/box housing from clutch housing and remove the 2 x 13mm bolts inside. There is also one 13mm bolt on side of gearbox case which secures a small internal shaft off to the side. It is dead obvious and didn't take a pic. But the whole housing should just slide off the top now revealing both shafts, forks, gears etc.

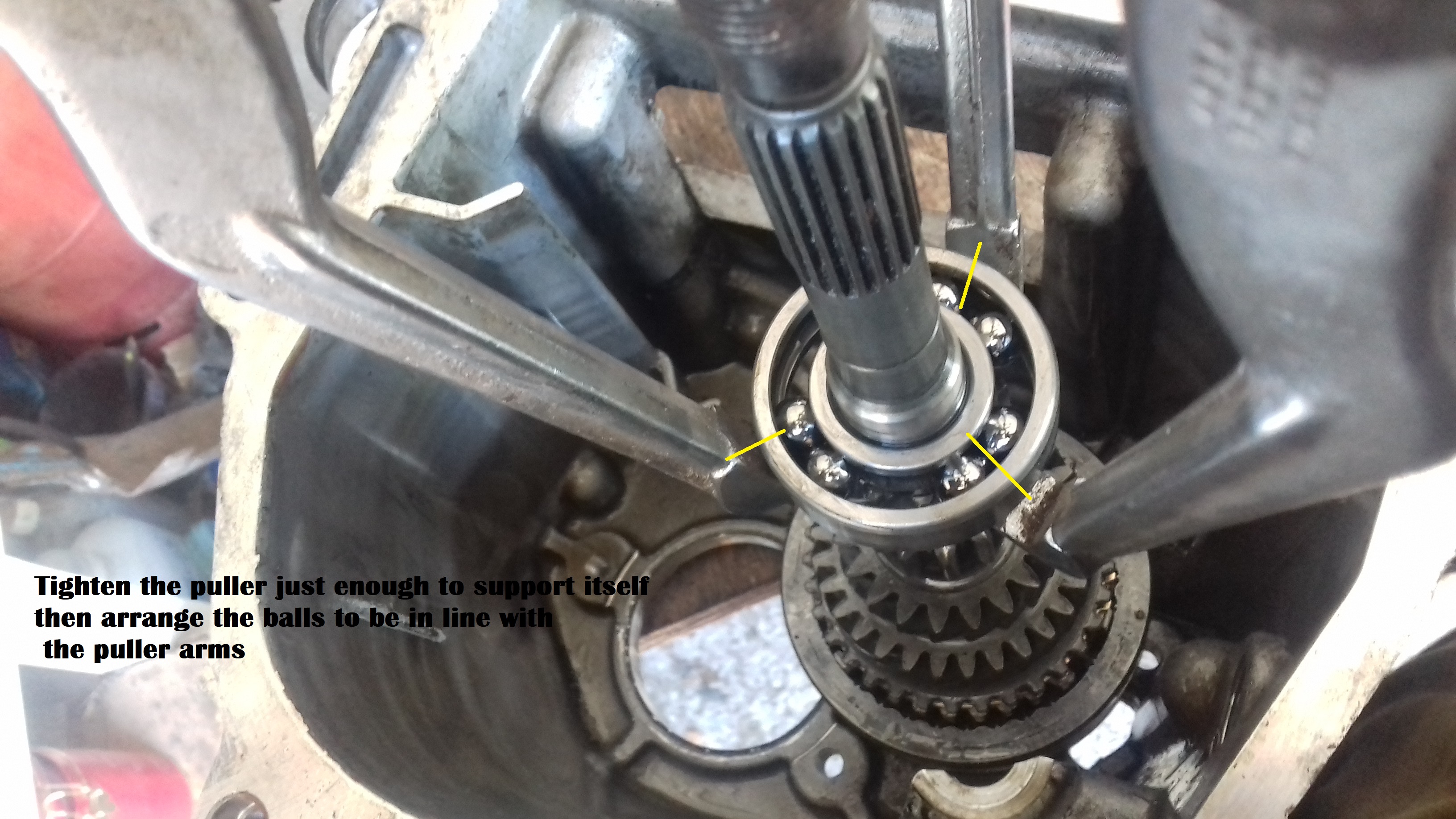

8) To remove the problem bearing I slightly tightened a 3 prong puller then arranged the balls in the race so that they lined up with the puller arms, I found this stopped the races from buckling as packed out where needed, IE where the pulling force was located.

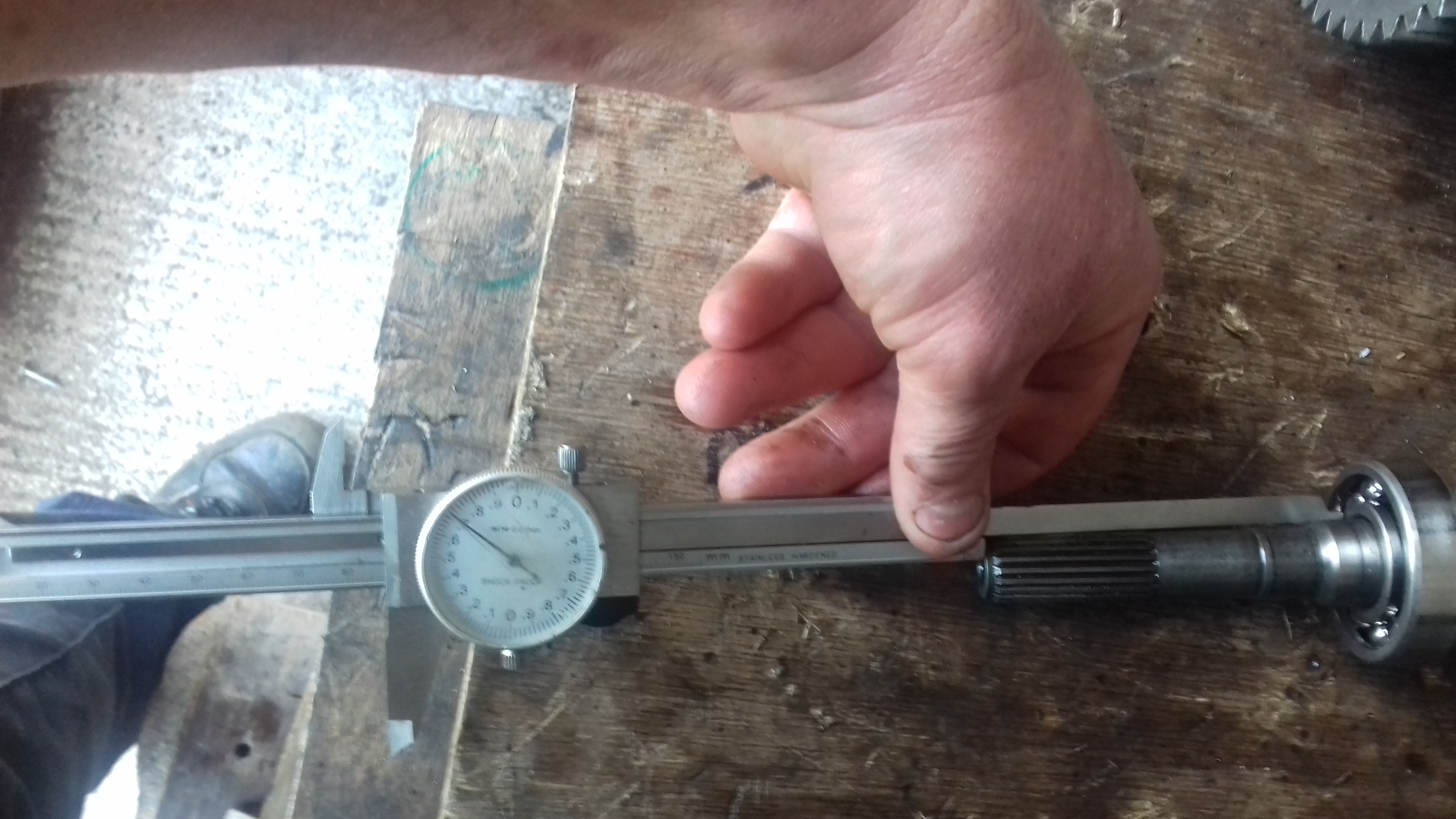

You can see from this last photo that it looks like the bearing has been in different positions on the shaft for a while so not actually sure where the true position should be but I did take a measurement of it last resting place as some kind of reference before I began to remove the bearing.

8) Measurement from end of input shaft to shoulder of inner race was 87.70mm

9) And here is what is on the bearing, it's an SKF and is definitely the original as we have had the car from new (2010). I don't recognise the classification and even close up not certain what they say but will get the magnifying glass out and update if I can see them any better. Hope that is of some use to people. I have yet to decide which bearing I'm going to replace it with but leaning towards a roller bearing probably NJ204. Again will update what I go with. By the way I am replacing the oil seal too but I presume no photo's needed for that. But do have a photo of depth to seal so you have a good idea when it is seated. From shoulder of casting to metal outer ring is 14.80mm

1) Clutch slipping above 2000 rpm (surprised any bite at all when I saw how much oil in clutch housing and on clutch itself.

2) Evidence of drips at bottom of clutch housing.

3) gearbox and cutch housing removed and inspection.

The sound isn't the throw bearing or fork, it is the shaft knocking.

Last time I did the clutch I don't recall seeing this crack like mark and maybe I notice now as the oil covering makes it stand out ? So with the amount of oil I now don't know if it is down to a crack in the rear of the crown gear space ? There also looks like welding spatter, so then I start to suspect perhaps they are just casting marks ?

And notice there are other crack like lines around the housing which weren't so visible when I did clutch 4 years ago. Anyway I still don't know for sure and will have to hope it is just the seal and bearing and keep an eye on things once it boxed up again.

5) Next step I wanted to see if could separate g/box from clutch housing and remove bearing and seal without taking gears out. Once separated and waggling apart slightly I found 2 x 13mm bolts which prevent it from coming free so removed those and then saw part of collapsed cage and at that point didn't know if a ball was missing as didn't know how many in the original bearing.

6) It was at this point I thought best to strip down and clear out any bits from the diff and the g/box itself so removed the g/box end cover and quickly discovered if you decide to strip it would have been easier not to remove the already removed 2 x 13mm bolts because I could not remove the large 30mm pinion nuts. So I put the 2x13mm bolts back in, hooked up to the ball and fixed the g/box case back to the clutch housing with just a couple of bolts, it was then rigid enough to move selectors as shown which locked the shafts and then enable me to remove the 2 x 30mm nuts. Had to ratchet strap the g/box down to a table to get enough grip to loosen the big nuts.

T

This pic was provided by my brother, to show position of selectors required to lock shafts, courtesy of the internet some place.

7) After removing the large nuts, remove the bolt from the fork and then everything above the plate with the Alen bolts in will just pry off easy enough. Then remove the countersunk Alen bolts and that plate. This then reveals the end bearings on both shafts which are held in place by large circlip. Following the removal of those go back to step 5 and separate the g/box housing from clutch housing and remove the 2 x 13mm bolts inside. There is also one 13mm bolt on side of gearbox case which secures a small internal shaft off to the side. It is dead obvious and didn't take a pic. But the whole housing should just slide off the top now revealing both shafts, forks, gears etc.

8) To remove the problem bearing I slightly tightened a 3 prong puller then arranged the balls in the race so that they lined up with the puller arms, I found this stopped the races from buckling as packed out where needed, IE where the pulling force was located.

You can see from this last photo that it looks like the bearing has been in different positions on the shaft for a while so not actually sure where the true position should be but I did take a measurement of it last resting place as some kind of reference before I began to remove the bearing.

8) Measurement from end of input shaft to shoulder of inner race was 87.70mm

9) And here is what is on the bearing, it's an SKF and is definitely the original as we have had the car from new (2010). I don't recognise the classification and even close up not certain what they say but will get the magnifying glass out and update if I can see them any better. Hope that is of some use to people. I have yet to decide which bearing I'm going to replace it with but leaning towards a roller bearing probably NJ204. Again will update what I go with. By the way I am replacing the oil seal too but I presume no photo's needed for that. But do have a photo of depth to seal so you have a good idea when it is seated. From shoulder of casting to metal outer ring is 14.80mm

Damn you are an old hand at this and in my neck of the woods too, I should have got in touch with you first before I did my last post with the photo's because you obviously won't need them. Thanks for info mateYes it can, the same gearbox was fitted to turbo cars that had 3x the torque of the 1.2 VVT and some of which were modified to over 4x the torque

£6 Is new old stock surplus, somebody in Germany has a shed load of then. Been selling them on eBay for several years

Watch the shipping cost, now we aren't in the EU

Buy the bearing new, They are very specialized. They have a reinforcing ring in one side. They are about $35 last I looked., compared $4 for the bearing used elsewhere in the gearbox

I don't know why they havr chosen this bearing,

The oil flow to the bearing has been improved on latter gearboxes, I beleive but haven take an early box apart

But there must be a reason why they spend more, especially when you are producing tens of millions of these boxes

It's up to you what you fit., Any bearing that's dimensionally the same, allows the same oil flow and C3 will probably do

I have taken 2 panda gearboxes apart and 1 fiat 500, the input shaft bearing has run dry in all of them,

Which failed first i don't know, oil seal then bearing, bearing then oil seal.

But my last 2 pandas did nearly 400K miles between them on the original bearings

Maybe the answer is a touch more oil in the gearbox over the stated capacity ? What do think of the crack like marks in my photo's ? Have you seen that in the ones you have done ? Just casting marks ?Yes it can, the same gearbox was fitted to turbo cars that had 3x the torque of the 1.2 VVT and some of which were modified to over 4x the torque

£6 Is new old stock surplus, somebody in Germany has a shed load of then. Been selling them on eBay for several years

Watch the shipping cost, now we aren't in the EU

Buy the bearing new, They are very specialized. They have a reinforcing ring in one side. They are about $35 last I looked., compared $4 for the bearing used elsewhere in the gearbox

I don't know why they havr chosen this bearing,

The oil flow to the bearing has been improved on latter gearboxes, I beleive but haven take an early box apart

But there must be a reason why they spend more, especially when you are producing tens of millions of these boxes

It's up to you what you fit., Any bearing that's dimensionally the same, allows the same oil flow and C3 will probably do

I have taken 2 panda gearboxes apart and 1 fiat 500, the input shaft bearing has run dry in all of them,

Which failed first i don't know, oil seal then bearing, bearing then oil seal.

But my last 2 pandas did nearly 400K miles between them on the original bearings

Looking through your photo at the momentMaybe the answer is a touch more oil in the gearbox over the stated capacity ? What do think of the crack like marks in my photo's ? Have you seen that in the ones you have done ? Just casting marks ?

All looks good so far

All 7 balls present is good, it's unlikely there will be any other damage

Most cars only get fresh gear oil and topped up when the clutch is changed.

Didn't notice the edits earlier mate. Any idea what the gap is ? G/box oil was changed at 20k then when clutch failed at 44k and checked in between. It did not need any top ups. There was no issue with oil in clutch housing at last failure but thinking about it, it was probably the beginning of the end for the bearing as a constant whirring noise after new clutch fitted. I blamed the cheapy ebay clutch at the time. It obviously got worse but my Mrs hardly uses it and only notices anything when she aims it and it doesn't move.5 speed gearbox

The original has 7 ball bearings with a glass reinforced polyamide (plastic) cage no seals

Very expensive

6204.A.G15J30

Plenty have fitted standard bearings

SKF Explorer 6204 C3 for example

Please note the bearing does not go tight against the gear there is a small gap, Fiat use a special tool, but can be done with feeler guages or suitable spacer

6 speed in higher power cars have roller bearings not need in the 1.2 and 1.2

Sounds like the bearings run dry and/or over heated. In good clean oil they are good for over 200K miles

We normally only see the diesel crankshaft seal goShould I replace crankshaft seal while clutch is off ? Or leave well alone ? Anybody know what the service life of that seal is ?

The Mrs Panda has only done 53k miles since 2010, first clutch change was at 44k and now this.

If you keep on top of the oil change it unlikely to fail in my opinion

Might depend who driving it where its being driven, luck, weight in carDidn't notice the edits earlier mate. Any idea what the gap is ? G/box oil was changed at 20k then when clutch failed at 44k

I normally get over 120,000 miles out of the original AP clutch

It's flat round here so helps, as does driving without passrngers

Didn't notice the edits earlier mate. Any idea what the gap is ?

Clutch slip 2004 Panda 1.2 | FIAT Panda (Mk3)

My clutch has recently started slipping, only under load - on hills or acceleration. The revs rise and I have to back off to stop it slipping. No history of a new clutch or hydraulics, 103k miles. Pedal action is fine, clutch engages and disengages fine. I suspect oil contamination. Recently...

So your gap about 3 stanley blades (75 thou approx) and his gap was 25 thou. I think that proves what I was thinking in my photo's to be correct, that the bearing has indeed moved and resettled. So measuring the clearance gap from inner race to gear after failure may not be to original spec clearance. I think I will measure everything tomorrow, from housing to housing and see what is left minus the 14mm for the bearing.

Clutch slip 2004 Panda 1.2 | FIAT Panda (Mk3)

My clutch has recently started slipping, only under load - on hills or acceleration. The revs rise and I have to back off to stop it slipping. No history of a new clutch or hydraulics, 103k miles. Pedal action is fine, clutch engages and disengages fine. I suspect oil contamination. Recently...www.fiatforum.com

Just to give some more context for those that have yet to experience this problem.

1) Clutch slipping above 2000 rpm (surprised any bite at all when I saw how much oil in clutch housing and on clutch itself.

2) Evidence of drips at bottom of clutch housing.View attachment 424767

3) gearbox and cutch housing removed and inspection.

View attachment 424769

View attachment 424768

The sound isn't the throw bearing or fork, it is the shaft knocking.

Last time I did the clutch I don't recall seeing this crack like mark and maybe I notice now as the oil covering makes it stand out ? So with the amount of oil I now don't know if it is down to a crack in the rear of the crown gear space ? There also looks like welding spatter, so then I start to suspect perhaps they are just casting marks ?

And notice there are other crack like lines around the housing which weren't so visible when I did clutch 4 years ago. Anyway I still don't know for sure and will have to hope it is just the seal and bearing and keep an eye on things once it boxed up again.

View attachment 424770

View attachment 424771

5) Next step I wanted to see if could separate g/box from clutch housing and remove bearing and seal without taking gears out. Once separated and waggling apart slightly I found 2 x 13mm bolts which prevent it from coming free so removed those and then saw part of collapsed cage and at that point didn't know if a ball was missing as didn't know how many in the original bearing.

View attachment 424772View attachment 424773View attachment 424774

6) It was at this point I thought best to strip down and clear out any bits from the diff and the g/box itself so removed the g/box end cover and quickly discovered if you decide to strip it would have been easier not to remove the already removed 2 x 13mm bolts because I could not remove the large 30mm pinion nuts. So I put the 2x13mm bolts back in, hooked up to the ball and fixed the g/box case back to the clutch housing with just a couple of bolts, it was then rigid enough to move selectors as shown which locked the shafts and then enable me to remove the 2 x 30mm nuts. Had to ratchet strap the g/box down to a table to get enough grip to loosen the big nuts.View attachment 424775

T

View attachment 424776

This pic was provided by my brother, to show position of selectors required to lock shafts, courtesy of the internet some place.View attachment 424777

7) After removing the large nuts, remove the bolt from the fork and then everything above the plate with the Alen bolts in will just pry off easy enough. Then remove the countersunk Alen bolts and that plate. This then reveals the end bearings on both shafts which are held in place by large circlip. Following the removal of those go back to step 5 and separate the g/box housing from clutch housing and remove the 2 x 13mm bolts inside. There is also one 13mm bolt on side of gearbox case which secures a small internal shaft off to the side. It is dead obvious and didn't take a pic. But the whole housing should just slide off the top now revealing both shafts, forks, gears etc.

View attachment 424778

8) To remove the problem bearing I slightly tightened a 3 prong puller then arranged the balls in the race so that they lined up with the puller arms, I found this stopped the races from buckling as packed out where needed, IE where the pulling force was located.

View attachment 424779View attachment 424780

View attachment 424783

You can see from this last photo that it looks like the bearing has been in different positions on the shaft for a while so not actually sure where the true position should be but I did take a measurement of it last resting place as some kind of reference before I began to remove the bearing.

8) Measurement from end of input shaft to shoulder of inner race was 87.70mm View attachment 424781View attachment 424782

9) And here is what is on the bearing, it's an SKF and is definitely the original as we have had the car from new (2010). I don't recognise the classification and even close up not certain what they say but will get the magnifying glass out and update if I can see them any better. Hope that is of some use to people. I have yet to decide which bearing I'm going to replace it with but leaning towards a roller bearing probably NJ204. Again will update what I go with. By the way I am replacing the oil seal too but I presume no photo's needed for that. But do have a photo of depth to seal so you have a good idea when it is seated. From shoulder of casting to metal outer ring is 14.80mm

View attachment 424784

View attachment 424785

Also just to clarify in my scribble and pics, when I mention bolt/nut sizes I'm referring to AF/spanner/socket sizes, not thread size.

- Joined

- Sep 14, 2009

- Messages

- 19,492

- Points

- 3,294

The 100HP (Six speed) and Multijet (diesel) have a much bigger input bearing. It's a substantial uncaged roller. I believe the failure is caused by the gear adjacent to the bearing throwing oil away before it can reach the bearing.

I replaced the bearing in our 1.2 with an SKF as mentioned at top of this thread. I used a three leg puller modified with longer crank arms to allow for the long shaft. I did not set the gap as discussed above but have had zero problems. I believe the issue is fitting the new bearing so it cannot bottom out in the housing. The gap should not be greater than that used by the old bearing.

My 100HP had the input oil seal fail. Thankfully, the bearing (uncaged roller) was as good as new - it looks extremely expensive. It offer zero thrust tolerance. That all happens at the other end. The much bigger the roller bearing is not shielded from oil splash by the adjacent gear. Reverse gear is the same as the 1200 gearbox.

The 2009 diesel input bearing is similar to the 100HP but 5 speed only.

I replaced the bearing in our 1.2 with an SKF as mentioned at top of this thread. I used a three leg puller modified with longer crank arms to allow for the long shaft. I did not set the gap as discussed above but have had zero problems. I believe the issue is fitting the new bearing so it cannot bottom out in the housing. The gap should not be greater than that used by the old bearing.

My 100HP had the input oil seal fail. Thankfully, the bearing (uncaged roller) was as good as new - it looks extremely expensive. It offer zero thrust tolerance. That all happens at the other end. The much bigger the roller bearing is not shielded from oil splash by the adjacent gear. Reverse gear is the same as the 1200 gearbox.

The 2009 diesel input bearing is similar to the 100HP but 5 speed only.

This is just for anybody out there that has to take seal out. I know many get a screw started and then pull at the seal with mole grips/pliers etc but if you place piece of timber across and lever with a claw hammer, no effort at all required. By the way grind point off screws as you don't want them bottoming in the shoulder.

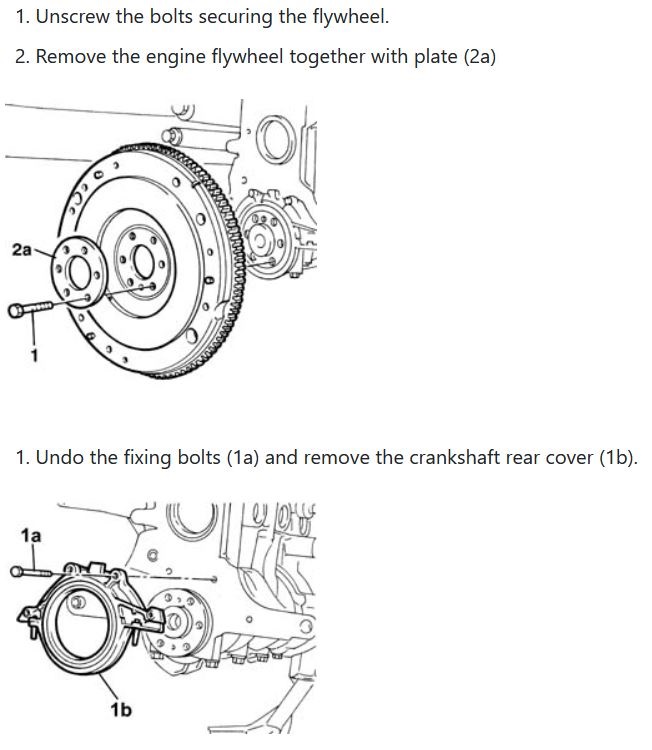

Now can anybody please tell me if the surface area of the flywheel that mates with the friction plate should be slighter lower than the area/ring that surrounds it ? And in general what to look for to decide it is past its best ? First photo is with a square across the surface and can see it touches on that outer ring only but the gap does does look consistent and even all the way round. TIA

While I have got this far I have decided to replace crankshaft seal. Luckily my Mrs isn't desperate for the motor, so bit of a wait for various bits and pieces to be delivered isn't an issue. Anyway a bit of a show of my setup. I'm by no means a pro, it has just turned out over the years I was the one that half volunteered/got landed with family/friends etc motors for brakes, oil changes, MOT type stuff etc. So some time ago I built these ramps as one thing I hated was being low down for brakes etc. They are a sort of halfway house cheap compromise rather than having a lift and been extremely useful over the years

. Plus I made a little bogey for them and can wheel them out of the way when not needed. They are not so good when clutch goes though as had to chain block the Panda up the ramp !

. Plus I made a little bogey for them and can wheel them out of the way when not needed. They are not so good when clutch goes though as had to chain block the Panda up the ramp !

Last edited:

Here my 1.2 69hp they should have a 200mm clutch plate that covered the full mating surface.Now can anybody please tell me if the surface area of the flywheel that mates with the friction plate should be slighter lower than the area/ring that surrounds it ? And in general what to look for to decide it is past its best ? First photo is with a square across the surface and can see it touches on that outer ring only but the gap does does look consistent and even all the way round. TIAView attachment 424907View attachment 424906