Hi all,

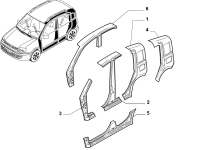

it seem that right side sill on my Panda rusted away, so I'm trying to get a replacement. However, scanning through eper, there is a difference between normal sills (71734757) that have reasonable price and availability, and Climbing sills (71738307), that are absolutely nowhere to be found (except Fiat dealer for hefty 692,75 EUR in Czechia). Does anyone know whether the normal sill can be used or reasonably hand fitted? And whats the difference? Many thanks for help.

it seem that right side sill on my Panda rusted away, so I'm trying to get a replacement. However, scanning through eper, there is a difference between normal sills (71734757) that have reasonable price and availability, and Climbing sills (71738307), that are absolutely nowhere to be found (except Fiat dealer for hefty 692,75 EUR in Czechia). Does anyone know whether the normal sill can be used or reasonably hand fitted? And whats the difference? Many thanks for help.

- Model

- Climbing Panda 4x4

- Year

- 2008

- Mileage

- 101000