Hi

I've re-con my head cylinder of my 999cc uno (carb).

Car was fine for 4 days, but drove with unadjustment distributor, so the engine had ringing noise when I press the gas all the way.

After 4 days, I drove at 120KM/H gas all the way, and suddenly big white smoke.

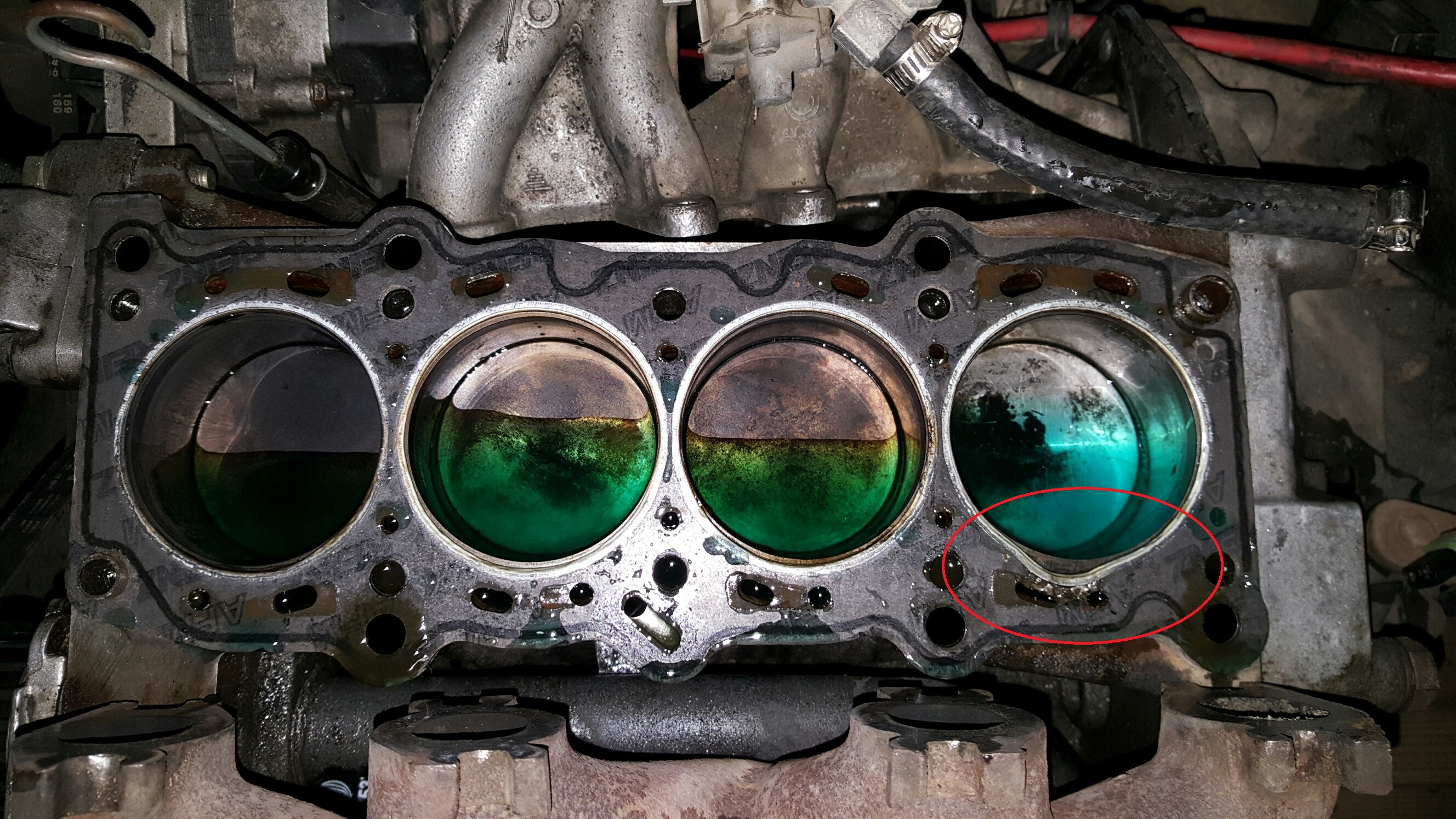

This is what I see after I took off the head again:

What could cause that?

I've closed the head exactly at 20nm, then 30nm, then 2 times 90*.

My friend told me the head may be low height, and that it would happen again if I put a new head gasket.

I've re-con my head cylinder of my 999cc uno (carb).

Car was fine for 4 days, but drove with unadjustment distributor, so the engine had ringing noise when I press the gas all the way.

After 4 days, I drove at 120KM/H gas all the way, and suddenly big white smoke.

This is what I see after I took off the head again:

What could cause that?

I've closed the head exactly at 20nm, then 30nm, then 2 times 90*.

My friend told me the head may be low height, and that it would happen again if I put a new head gasket.