puck304

New member

Hi all,

I have the dual zone climate control with AC. The temperature is fine. The fan output is crap. The fan turns on and off. It come on when you turn it on, then maybe one level more as you increase the level and it stays at that level all the way up through the display.

The fan turns on and off. It come on when you turn it on, then maybe one level more as you increase the level and it stays at that level all the way up through the display.

I took it to a non-main dealer Fiat garage, who are good; they plugged the diagnostic kit in and it threw up a few fault codes:

B1922 Electric fan feedback present, O.C. or S.C. to Ground or Rotor blocked

B1907 Feet/vent flap actuator Intermittent Rotor Block

B1906 Feet/Chest motor feedback.Present O.C. or S.C. to +Batt.V.

Deckchair 5, you say 'B1922 Sounds like the fan is struggling electrically either with a physical restriction (might be leaves in fan) or the speed control CB in the fan motor on climate control cars. The B1906 and 7 are either sticking motors/ sticking vanes or poor wiring contacts on the B1906.'

I've replaced cabin filter and stuck a hoover nozzle in there too. When I first did that when first getting the car last year, there wasn't a cabin filter in there :bang:

Sounds like I need to pull the fan out then?

If there's no leaves in there, what would I need to look for on the speed control CB?

Could anyone also explain a bit more about 'The B1906 and 7 are either sticking motors/ sticking vanes or poor wiring contacts on the B1906'?

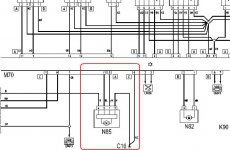

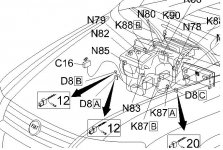

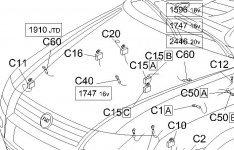

I've disconnected the connector to the fan, and put a multimeter across the feed and earth outputs; it shows just over 12V. The fuse by the battery looks ok and I cleaned up the contacts on the relay. I don't how to test the relay or how it would show itself to be faulty?

I have the dual zone climate control with AC. The temperature is fine. The fan output is crap.

I took it to a non-main dealer Fiat garage, who are good; they plugged the diagnostic kit in and it threw up a few fault codes:

B1922 Electric fan feedback present, O.C. or S.C. to Ground or Rotor blocked

B1907 Feet/vent flap actuator Intermittent Rotor Block

B1906 Feet/Chest motor feedback.Present O.C. or S.C. to +Batt.V.

Deckchair 5, you say 'B1922 Sounds like the fan is struggling electrically either with a physical restriction (might be leaves in fan) or the speed control CB in the fan motor on climate control cars. The B1906 and 7 are either sticking motors/ sticking vanes or poor wiring contacts on the B1906.'

I've replaced cabin filter and stuck a hoover nozzle in there too. When I first did that when first getting the car last year, there wasn't a cabin filter in there :bang:

Sounds like I need to pull the fan out then?

If there's no leaves in there, what would I need to look for on the speed control CB?

Could anyone also explain a bit more about 'The B1906 and 7 are either sticking motors/ sticking vanes or poor wiring contacts on the B1906'?

I've disconnected the connector to the fan, and put a multimeter across the feed and earth outputs; it shows just over 12V. The fuse by the battery looks ok and I cleaned up the contacts on the relay. I don't how to test the relay or how it would show itself to be faulty?