I've decided to replace the stem valve seals on my Punto 1.2 8V, as there are signs that I need to do this.

The engine runs well, but consumes a lot of oil, about 1.5 l in 1.000 kms and there are traces of oil in the combustion chambers, especially on the plugs as those are the parts I could see. There was oil on the plugs threads, so obviously oil gets inside the combustion chambers, kind of the same on all cylinders.

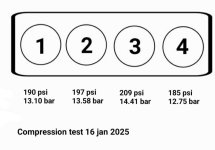

Compression test showed this:

1. 13.10 bar

2. 13.58 bar

3. 14.41 bar

4. 12.75 bar

Those are very good readings, meaning the piston rings are ok, I was dreaded the idea that them might need replacement. The car has over 250k km on the clock (~155k miles). The test was done with just one reading, without ingecting oil into chambers (wet testing) as those numbers told me the rings are good so the oil obviously comes through the stem valves. So I thought there's no need to add more oil. Also, the engine was not on working temperature while testing, but I've started it before not to be cold. It was warm-ish.

It's the first CH work I will do myself, so I welcome any good advice.

Last time I had the CH rebuild (took it to a specialist) was in 2018 and after that the oil was not on good levels, but I had to discover later on that the oil was leaking through the camshaft seal. By the time I'd replace that seal I think the stem seals started to leak, probably oil leaking contributed to early worn-out of stem seals. By the way, do you have any idea of what is the lifespan of stem seals?

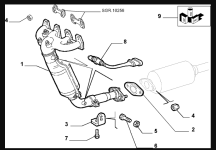

That time the specialist did not put a new seal, used the old one and I think that he even put the seal in place with the bracket off and then put the bracket on and tighten the screws. I don't think that that is the correct way to put that seal on. I think the proper way is to place the brackets, tighten the bolts and then place the seal from the ouside in, like any other seal. This is the way I'm gonna do it.

My first question is about the torque wrench settings, as Fiat has these silly recommendations with angle-tightening that I'm not gonna use. I'll just use the torque wrench and the cylinder head bolts I'm gonna tighten as I remember the mechanic did on my Punto in 2018, in these 4 steps:

1. 20Nm

2. 30 Nm

3. 70 Nm

4. 90 Nm

Do you agree with those numbers and do you have the numbers for the rest of bolts where Fiat recomands angle-tightening? I'm putting the recommendations from the Haynes manual and pics with how things are and what I'mdoing.

I will add pictures and details as I go along.

The engine runs well, but consumes a lot of oil, about 1.5 l in 1.000 kms and there are traces of oil in the combustion chambers, especially on the plugs as those are the parts I could see. There was oil on the plugs threads, so obviously oil gets inside the combustion chambers, kind of the same on all cylinders.

Compression test showed this:

1. 13.10 bar

2. 13.58 bar

3. 14.41 bar

4. 12.75 bar

Those are very good readings, meaning the piston rings are ok, I was dreaded the idea that them might need replacement. The car has over 250k km on the clock (~155k miles). The test was done with just one reading, without ingecting oil into chambers (wet testing) as those numbers told me the rings are good so the oil obviously comes through the stem valves. So I thought there's no need to add more oil. Also, the engine was not on working temperature while testing, but I've started it before not to be cold. It was warm-ish.

It's the first CH work I will do myself, so I welcome any good advice.

Last time I had the CH rebuild (took it to a specialist) was in 2018 and after that the oil was not on good levels, but I had to discover later on that the oil was leaking through the camshaft seal. By the time I'd replace that seal I think the stem seals started to leak, probably oil leaking contributed to early worn-out of stem seals. By the way, do you have any idea of what is the lifespan of stem seals?

That time the specialist did not put a new seal, used the old one and I think that he even put the seal in place with the bracket off and then put the bracket on and tighten the screws. I don't think that that is the correct way to put that seal on. I think the proper way is to place the brackets, tighten the bolts and then place the seal from the ouside in, like any other seal. This is the way I'm gonna do it.

My first question is about the torque wrench settings, as Fiat has these silly recommendations with angle-tightening that I'm not gonna use. I'll just use the torque wrench and the cylinder head bolts I'm gonna tighten as I remember the mechanic did on my Punto in 2018, in these 4 steps:

1. 20Nm

2. 30 Nm

3. 70 Nm

4. 90 Nm

Do you agree with those numbers and do you have the numbers for the rest of bolts where Fiat recomands angle-tightening? I'm putting the recommendations from the Haynes manual and pics with how things are and what I'mdoing.

I will add pictures and details as I go along.

- Model

- Punto mk2 1.2 8V

- Year

- 2005

- Mileage

- 154999