Dancingbear

Member

Hi all,

I’m hoping someone here might be able to shed some light on ongoing issues with my 2019 Fiat Ducato 35 Multijet II (250) ‘Sportivo’ twin-EGR, no AdBlue, currently on 84,000 miles.

Symptomatically they seem to mirror the EGR cooler syndrome that’s been well documented here, but none of the codes are the same: Over the last 8 months I’ve had the following fault codes:

March

P0683 – glow plug circuit - replaced

P0639 – throttle valve control - cleaned

P045E – EGR - HP replaced (in error)?

May

P045E – EGR - LP replaced

Aug

P041A – EGR temp sensor replaced

Spetember

P2002 – DPF efficiency below threshold (after failed motorway regeneration)

The first motorway journey after the Temp sensor was replaced, a DPF regen failed which initiated the P2002 code and EML.

Unfortunately these error codes have taken excessive times to be fixed and the van has been driven with the EML on – the Temp sensor code illuminated in the French Alps and we weren’t able to get it resolved until back in the UK – 1000 miles+… I now know the illuminated EML will prevent auto DPF regen .

.

Last week I had a mobile DPF specialist perform a diagnostic and clean at my home. The basics of his assessment were:

He noted soot present in the tailpipe (which I noted 6 months ago) and suggests the DPF is probably damaged (based on soot and zero / low DPF pressures).

As a massive curve ball to this already complex picture, the DPF guy found my turbo electrically unplugged – which must be from previous garage work - Time scales unknown. Once reconnected, turbo faults cleared and it appears to boost normally again – both on the road and on the diagnostics.

At this stage, I think I know the following:

I’ve purchased MultiECUScan - its in the post - so I can start logging and learning from the excellent posts many of you have already shared here. I’ve started reading through the twin-EGR and P0401/P0402 mega-thread, but because of the difference in presentation any different or targeted insight here would be hugely appreciated.

Before I dive in, some questions for you legends:

I’d really appreciate any informed thoughts or guidance on this!

Thanks in advance

I’m hoping someone here might be able to shed some light on ongoing issues with my 2019 Fiat Ducato 35 Multijet II (250) ‘Sportivo’ twin-EGR, no AdBlue, currently on 84,000 miles.

Symptomatically they seem to mirror the EGR cooler syndrome that’s been well documented here, but none of the codes are the same: Over the last 8 months I’ve had the following fault codes:

March

P0683 – glow plug circuit - replaced

P0639 – throttle valve control - cleaned

P045E – EGR - HP replaced (in error)?

May

P045E – EGR - LP replaced

Aug

P041A – EGR temp sensor replaced

Spetember

P2002 – DPF efficiency below threshold (after failed motorway regeneration)

The first motorway journey after the Temp sensor was replaced, a DPF regen failed which initiated the P2002 code and EML.

Unfortunately these error codes have taken excessive times to be fixed and the van has been driven with the EML on – the Temp sensor code illuminated in the French Alps and we weren’t able to get it resolved until back in the UK – 1000 miles+… I now know the illuminated EML will prevent auto DPF regen

Last week I had a mobile DPF specialist perform a diagnostic and clean at my home. The basics of his assessment were:

| Parameter | Pre-Clean | Post-Clean |

| DPF soot load (%) | 177 | 9 |

| ΔP at idle (kPa) | 0.4 | 0 |

| ΔP at 2500 rpm (kPa) | 2.2 | 0.7 |

| Engine temp (°C) | 80 | 94 |

| MAF (mg/stroke) | 448 | 386 |

| EGR position (%) | 0 | 0 |

| EGT (°C) | 628 | 184 |

He noted soot present in the tailpipe (which I noted 6 months ago) and suggests the DPF is probably damaged (based on soot and zero / low DPF pressures).

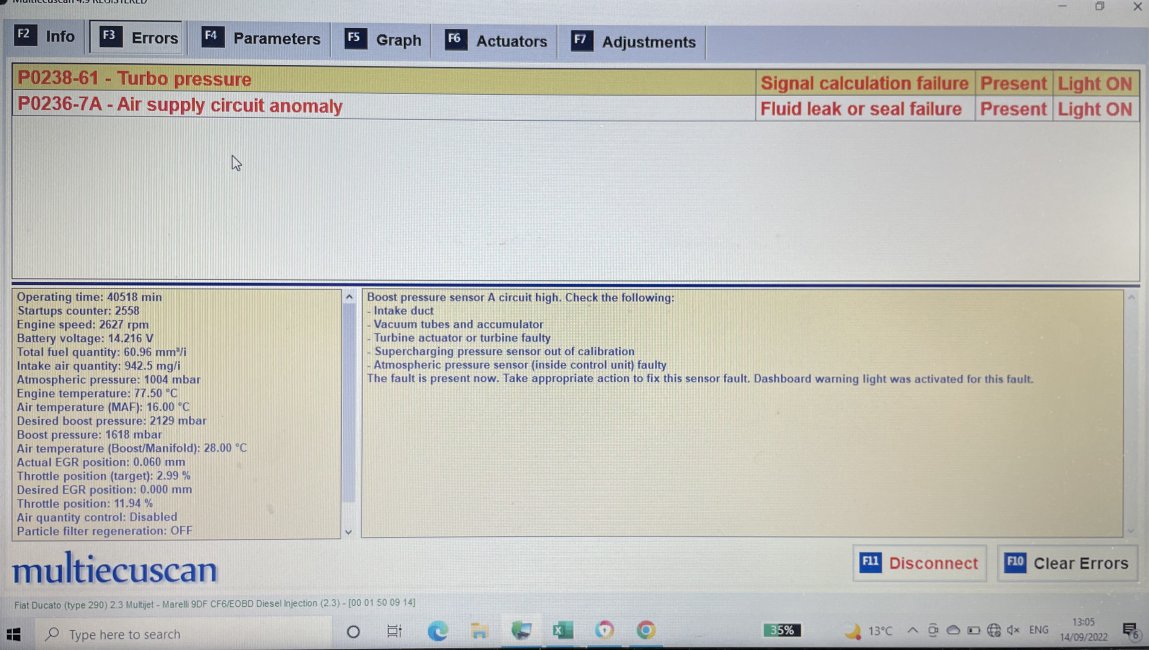

As a massive curve ball to this already complex picture, the DPF guy found my turbo electrically unplugged – which must be from previous garage work - Time scales unknown. Once reconnected, turbo faults cleared and it appears to boost normally again – both on the road and on the diagnostics.

At this stage, I think I know the following:

- This is going to be expensive!!!

- The DPF is almost certainly damaged and I have had soot in my exhaust for 6 months +

- The Turbo unplugged issue could be the root cause of this, as I imagine poor operation of the variable geometry in the turbo will make its operation ‘agricultural’ causing excessive soot! But it could also be only contributory or a complete red herring if it was only unplugged a few weeks with limited miles!???

I’ve purchased MultiECUScan - its in the post - so I can start logging and learning from the excellent posts many of you have already shared here. I’ve started reading through the twin-EGR and P0401/P0402 mega-thread, but because of the difference in presentation any different or targeted insight here would be hugely appreciated.

Before I dive in, some questions for you legends:

- Do these symptoms and readings suggest solely a cracked DPF or something else upstream (MAP / boost solenoid / EGR control, cooler etc etc.)?

- Would you DEFINITELY have to unplug the turbo to change LP or HP EGR or EGR Temp Sensor and therefore not plugged back in my my local garage?

- Whats the significance of the unplugged turbo?

- How would I be able to ‘prove’ that the garage left it unplugged?

- Any pointers on the next steps or first parameters I should log with MES to narrow this down?

I’d really appreciate any informed thoughts or guidance on this!

Thanks in advance

Last edited: