Updated 05/07/08

Finally as of last night - my time is free for a couple of weeks

James is also on holiday (being a school teacher) - so here we go, the push to the finish begins!

Starting about 11AM today, we moved the 164 out of my outside garage so we have somewhere to work on the removed panels (doors and bonnet) of the Uno - instead of cluttering the space around the Uno, they'll be primed and painted out in the other garage while the 164 weathers the elements.

The Uno was a bit more approachable with the doors, bonnet, and bumpers out of the way (picture). But the WEATHER - horrible! Temperature reached 9 degrees today (apparently) with scattered outbreaks of sun, fine showers, and heavy rain the rest of the time, strong winds, and winds in the usual prevailing westerly direction that drives the rain into my inside (i.e. attached-to-the-house) garage

James and I tend to work like insects - we speed up when the sun's shining on us - so we both found it difficult to get motivated today knowing that painting, etc. was out of the question. We decided to start with fitting a couple of new parts bought recently. The cam cover gasket/rubber seal had a small leak near the distributor - this is after we'd cleaned/fitted it with Loctite Master Gasket. I don't know if you know Master Gasket, but it's a close relative of the red threadlocking compound - it sets when there is no air between close-fitting flanges.

Master Gasket worked so well on the flat parts that James had to use a slide hammer to remove the cam cover - of course, it had still leaked anyway because the rubber seal was not a good fit over the curved part. The slide hammer, having proved to be poor at removing dents, was excellent at removing the bonded-on cam cover! Cleaning off the hardened Master Gasket was not an easy job. We eventually used some grey silicone sealer to seal the corners and the back surface of the new gasket (rubber seal).

Meanwhile I set about the simple satisfaction of changing the thermostat. Even though we hadn't been able to really drive the car due to a cooling system leak, I had my suspicions that the thermostat wasn't working - the radiator top hose was getting hot pretty quickly and the heater output wasn't much. On the Trademe auction site last week, I spotted a new, genuine FIAT thermostat for a 1998 Punto 75SX. That's a rare model in NZ, but the thermostat looked familiar, so I took a punt on it for $40. With the gasket.

Sure enough, it was an identical shape to the one on the good old 999cc FIRE. The coolant that I'd put in a few weeks back drained out easily (hint: flexible screwdriver makes an ideal hoseclamp tool because the socket for hex screwdriver bits is exactly the right size for hose clamps), and the coolant was still clean and bright green, almost fluorescent.

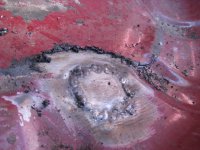

What made this little job even more satisfying was when the old thermostat came out in pieces! One of the posts had simply corroded away, so the centre was floating around, and also the plate had a ring of holes where there should have been a rubber seal. With the thermostat floating around, I'm sure that would have interfered with cooling flow to some extent and obviously didn't seal. (picture)

I re-used the coolant and refilled the system, trying to get the air out of the heater junction in the process (there's no bleed tap on this one, but even if there was, it's the highest point in the system so water won't reach it before the radiator overflows. A bit of a dumb design there - how can you get the air out? That's probably why Uno heaters usually gurgle when you turn them on - the air collects at the hoses. I think the best solution will be to add a bleed tap (I have one spare) and then make a 'head of water' by designing a tube to fit onto an old radiator cap and thus raise the water level above the bleed tap - that should work.

Come to think of it, if the radiator cap was fitted and the system run up to temperature, you could open the bleed tap (with the radiator cap on) and the pressure would force the water up to the bleed tap - so I guess I've answered my own question

Incidentally the Turbo does not have this air-in-the-heater-when-filling problem, because the expansion tank is the highest point.

I stopped for a lunch break at this point, so James continued with the welder making some reinforcements where there had been rust in the engine bay front corner. I think James did a bloody brilliant job in a very inaccessible place (picture). No actual patch went in - it was more a case of welding the existing inner wing to the chassis rail and to the towing eye bracket, where it should have been welded in the factory but never was!

Next I sent James out to the outside garage with the D/A sander and several doors to get the clearcoat, flaking paint etc. sanded off. I then stumbled around trying to solve a problem with the compressor's regulator (I could hear the sander zinging at well over its max pressure, then it would be too low to start, and my compressor was running all the time). Solution was to turn down the compressor's regulator so that less air got used by the sander and therefore the pressure would be more consistent - problem is, it's quite tricky to adjust a regulator when the air tool is starting and stopping! James worked solidly though and got all three doors sanded ready for primer/filler. Except the recessed bits behind the handles! I guess I'll do those by hand

I also kicked around looking for my fibre-filler and my spreader, the tiny hardener tube, etc. in order to start filling the bottom of one door. All the welding had been painted with POR-15 (American anti-rust paint) which sets extremely hard and shiny. (picture) thepottleflump - Trevor - eat your heart out - just look at how lumpy that welding is compared with my worst before! I'm proud to say that I didn't do it - so it's all *his* fault

Ironically there are still big holes in the outer doorskin despite the metres of welding to the door bottom. The door had been soaking in rust converter for a few days, then I chased what remaining rust there was with a strip-disc on an angle grinder, so I'm confident the rust should be gone for a long time IF I can make the bottom of the door waterproof and repair the great big holes in the outer skin. Watch this space.

I think it's fair to say that I didn't get much done - but I may get some work done by myself tomorrow - the date will be 06/07/08, yay - but otherwise, on Monday we're hoping for a fine day so that we can roll the shell outside and sand/clean it in all the corners ready for painting soon. Ideally the doors/bonnet will get primed on Monday also.

Keep those projects ticking

Cheers,

-Alex