Greetings everyone, this will be a bit complicated explanation.

-Previous fault lamp, irregular operation, stalling.

I had problems.

I determined that the map and eccentric cable were broken and repaired them.

-I detected some vacuum leaks. I fixed it.

Despite these, I thought my idling was not very good. I don't trust iacv very much. When I disassembled it before to clean it, the plastic came off easily. It has worn out over the years.

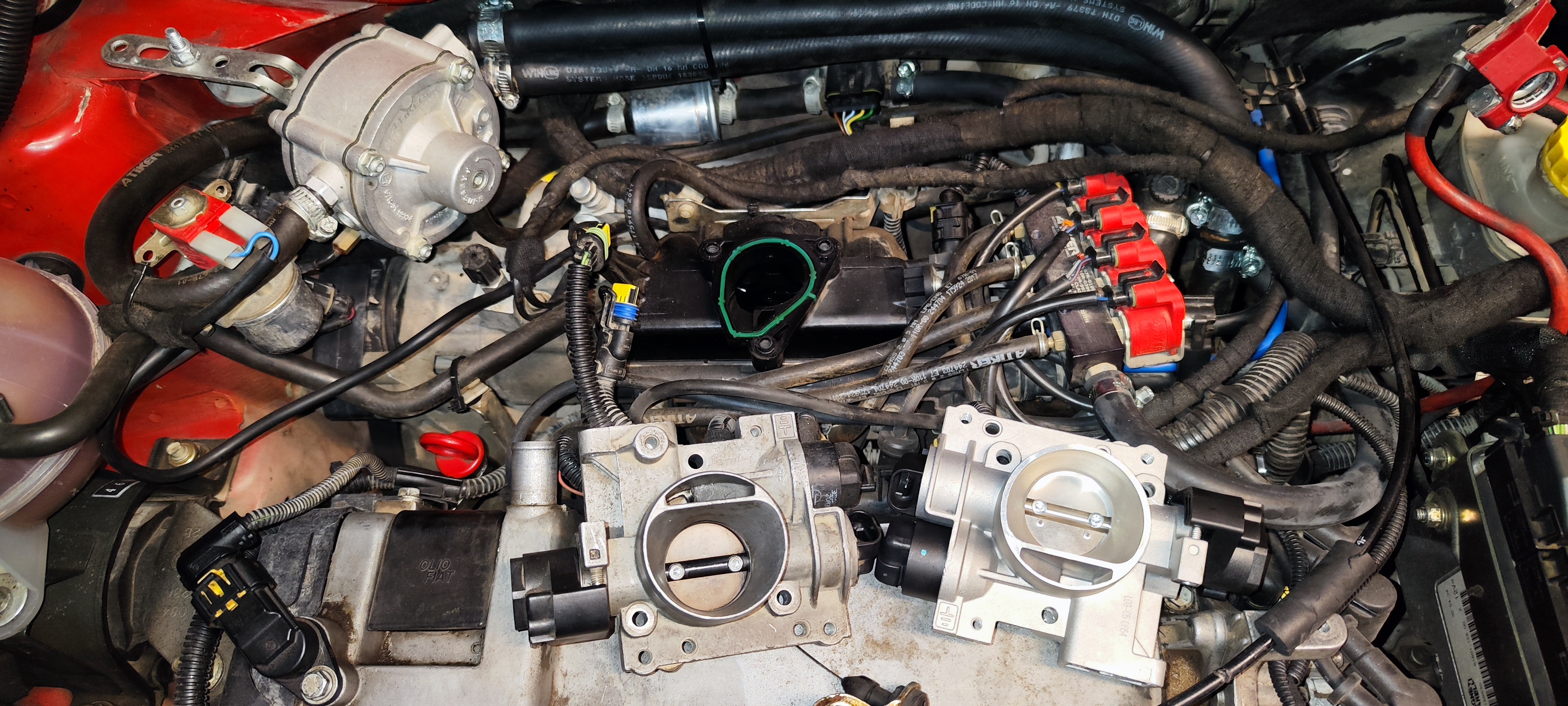

-While I was investigating the first malfunction above, I also purchased the throttle body.

Now I decided to assemble it.

After installing it, the idling performance of the car increased significantly.

The vehicle started to reach idle speed much more easily and quickly.So yes, my problem was here and it was fixed. I experienced very positive developments. The time I have to wait for the car to idle while stopping, starting and maneuvering has decreased.

Problem;

But despite its choppy operation, it never knocks or tends to stall. So my vacuum circuit is very healthy.

Question;

-Previous fault lamp, irregular operation, stalling.

I had problems.

I determined that the map and eccentric cable were broken and repaired them.

-I detected some vacuum leaks. I fixed it.

Despite these, I thought my idling was not very good. I don't trust iacv very much. When I disassembled it before to clean it, the plastic came off easily. It has worn out over the years.

-While I was investigating the first malfunction above, I also purchased the throttle body.

Now I decided to assemble it.

After installing it, the idling performance of the car increased significantly.

The vehicle started to reach idle speed much more easily and quickly.So yes, my problem was here and it was fixed. I experienced very positive developments. The time I have to wait for the car to idle while stopping, starting and maneuvering has decreased.

Problem;

- I guess he didn't recognize the new throttle body correctly.

- Sometimes the idle remains constant at 1400 rpm. (Too high) (I'm not talking about the automatic choke procedure)

- In general, it stays healthy at 800 rpm.

- Sometimes it is wavy like 800-500 -800-500rpm. It works.

But despite its choppy operation, it never knocks or tends to stall. So my vacuum circuit is very healthy.

The LPG circuit is a retrofitted circuit. When running on LPG, the rpm is currently around 1500. I need to go to the service to set this up. But the problems I am talking about now are the events that occur when the LPG system is turned off and the vehicle is started on gasoline.

Question;

- Is there any automatic identification procedure that I know of? Or is there?

- Also, when I disassembled the old TB, I observed that it was quite oily. There may be too much oil coming from the vapor recovery pipe.