turbo500

Member

- Joined

- Mar 20, 2013

- Messages

- 251

- Points

- 118

Hello everyone,

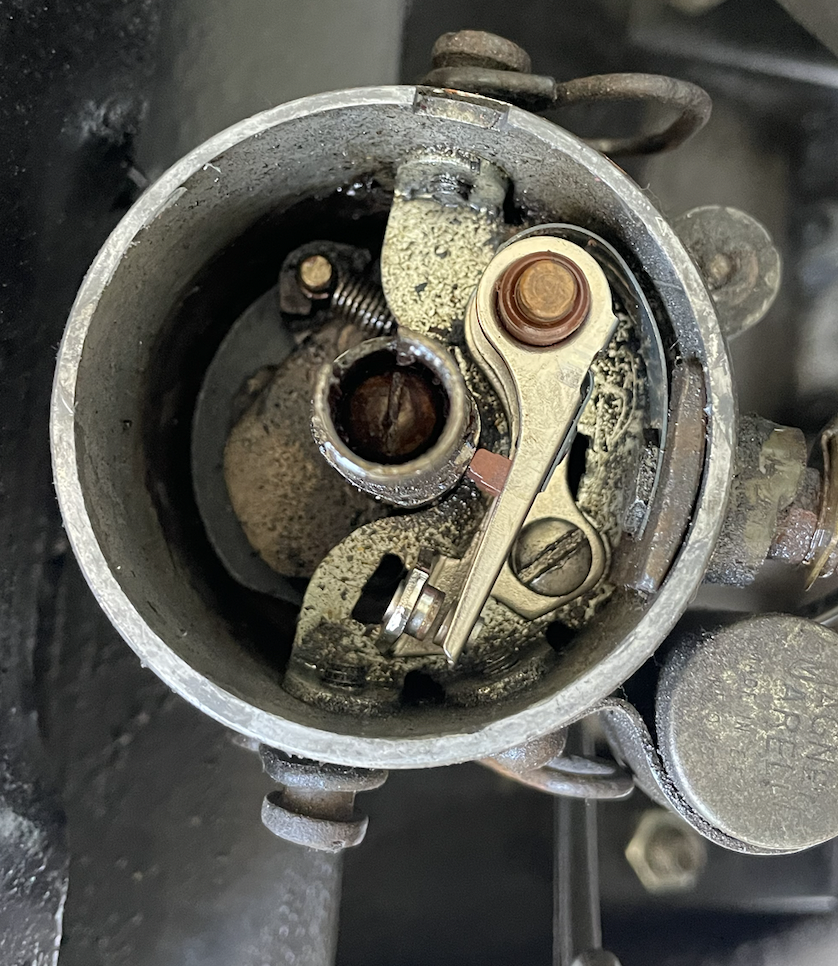

I recently upgraded to a 28IMB, have new bakelite spacer, new gaskets, new fuel pump. I'm struggling to get her started properly without cranking for a while with the choke on. Even with the choke, it doesn't always start properly at first. Tends to lower revs and stop.

I was reading other members similar issues, and it seemed to point towards incorrect gap in the breaker points of the ignition. So today I tried setting them to 0,50, moved the pulley until the gap was at it's furthest, measured and then set the gap. Nothing changed.

I replaced the points with a new set I had, and that too didn't change a thing. I have a new condenser to install but I don't think that will make a difference...

I've uploaded some pics, maybe you guys can see if something is wrong? Could the rotor arm be worn out?

Thank you for your help

I recently upgraded to a 28IMB, have new bakelite spacer, new gaskets, new fuel pump. I'm struggling to get her started properly without cranking for a while with the choke on. Even with the choke, it doesn't always start properly at first. Tends to lower revs and stop.

I was reading other members similar issues, and it seemed to point towards incorrect gap in the breaker points of the ignition. So today I tried setting them to 0,50, moved the pulley until the gap was at it's furthest, measured and then set the gap. Nothing changed.

I replaced the points with a new set I had, and that too didn't change a thing. I have a new condenser to install but I don't think that will make a difference...

I've uploaded some pics, maybe you guys can see if something is wrong? Could the rotor arm be worn out?

Thank you for your help