Introduction

The day i got the cinq sx with its crap racing stripes

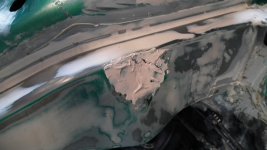

looking rather good for its age 1995 no rust no dents no deep scuffs

i previously owned a mk1 punto 60s but ive always wanted a cinq so after i purchased cinq i striped the punto down to bear chassis including engine and gearbox loom and so on ive been collecting parts for the 1.2 conversion for a while p75 cams full engine rebuild re skim using a big cnc machine from college

loom and so on ive been collecting parts for the 1.2 conversion for a while p75 cams full engine rebuild re skim using a big cnc machine from college  cinq gearbox and mounts ect

cinq gearbox and mounts ect

looking rather good for its age 1995 no rust no dents no deep scuffs

i previously owned a mk1 punto 60s but ive always wanted a cinq so after i purchased cinq i striped the punto down to bear chassis including engine and gearbox